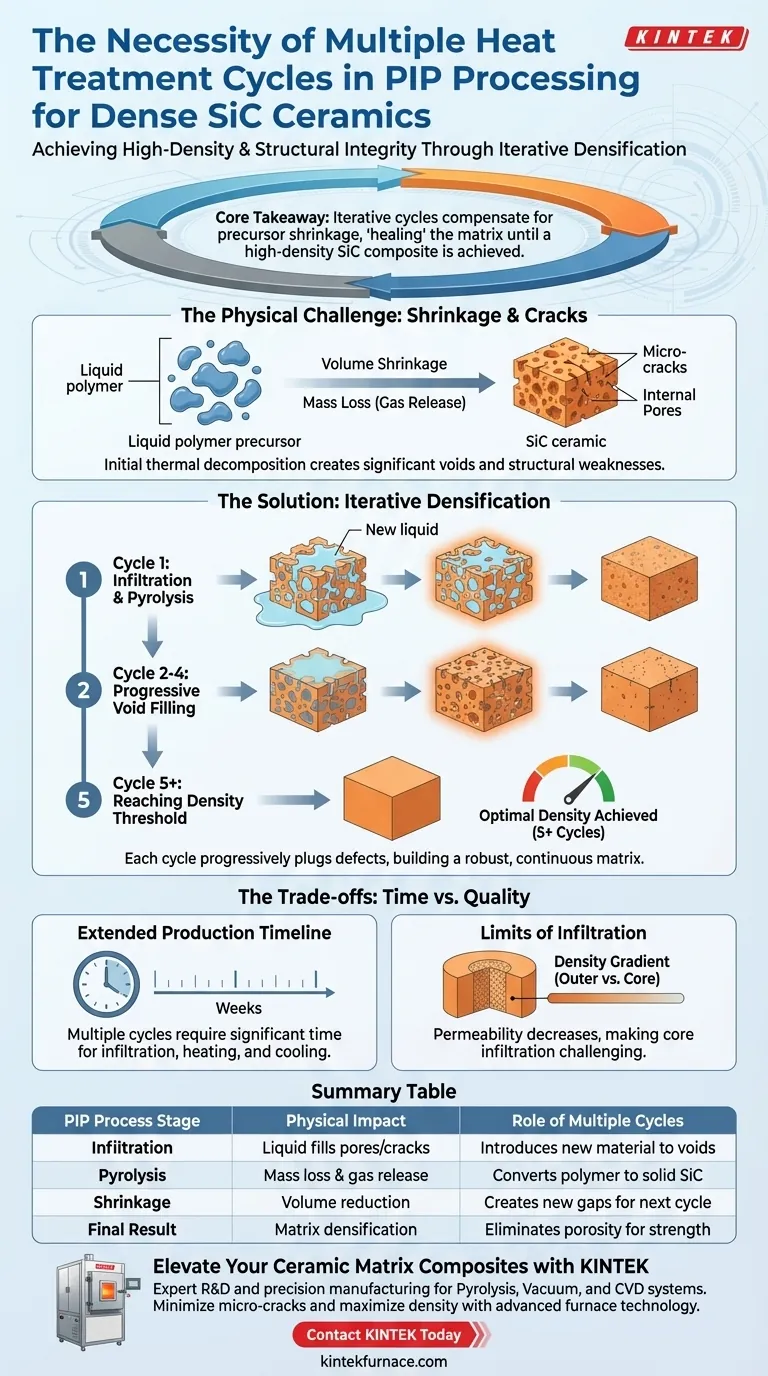

Multiple heat treatment cycles are essential because the conversion of liquid polymer precursors into solid SiC ceramics involves significant volume shrinkage and mass loss. This transformation naturally creates a network of micro-cracks and internal pores within the material. By repeating the infiltration and pyrolysis process, usually five or more times, new precursor material fills these voids, gradually increasing the density and structural integrity of the ceramic matrix.

Core Takeaway: PIP processing relies on iterative cycles to compensate for the inherent shrinkage of precursors during thermal decomposition, effectively "healing" the matrix until a high-density, high-performance SiC composite is achieved.

The Physical Challenge of Precursor Conversion

Volume Shrinkage and Mass Loss

During the pyrolysis phase, the polymer precursor undergoes a chemical breakdown to form a ceramic. This process releases gaseous byproducts, leading to a substantial reduction in the volume of the material.

As the liquid precursor transitions into a solid ceramic state, the loss of mass inevitably leaves behind empty spaces. Without further intervention, the resulting matrix would be too porous to provide adequate structural strength.

The Development of Micro-cracks

The internal stresses generated during thermal decomposition often exceed the strength of the nascent ceramic. This leads to the formation of a network of micro-cracks throughout the preform.

These cracks act as pathways for future infiltration but also represent structural weaknesses. Addressing these defects is the primary reason why a single heat treatment is insufficient for industrial-grade SiC ceramics.

The Mechanics of Iterative Densification

Progressive Void Filling

Each subsequent "impregnation-pyrolysis" cycle introduces fresh liquid precursor into the pores and cracks created by the previous heat treatment. When this new material is pyrolyzed, it solidifies within those gaps.

This iterative approach ensures that the density of the SiC matrix increases incrementally. Each cycle effectively "plugs" the defects of the last, building a more continuous and robust ceramic structure.

Reaching the Density Threshold

To achieve a high-density SiC ceramic matrix composite (CMC), a standard threshold of five or more cycles is typically required. Early cycles focus on filling large macro-pores, while later cycles target finer micro-porosity.

As the matrix becomes denser, the permeability of the material decreases. This makes each subsequent infiltration more challenging, eventually reaching a point of diminishing returns where the density stabilizes.

Understanding the Trade-offs

Time and Cost Implications

The primary downside of the PIP process is the extended production timeline. Because each cycle requires hours or days for infiltration, heating, and cooling, the total manufacturing time for a dense part can span several weeks.

Limits of Infiltration

As the matrix densifies, it becomes increasingly difficult for the liquid precursor to penetrate the center of the component. This can lead to a "density gradient," where the outer surface is denser than the core, potentially trapping gases inside during final heat treatments.

Achieving Optimal Matrix Integrity

- If your primary focus is Maximum Density: Perform at least five to eight cycles to ensure that even the finest micro-cracks are filled with ceramic material.

- If your primary focus is Production Efficiency: Monitor the mass gain after each cycle and stop the process once the incremental density increase falls below your required threshold.

- If your primary focus is Structural Uniformity: Ensure that infiltration times are sufficient in later cycles to allow the precursor to reach the inner geometry of the part.

Successful SiC ceramic formation is fundamentally a marathon of repeated thermal treatments designed to overcome the physical limitations of chemical shrinkage.

Summary Table:

| PIP Process Stage | Physical Impact | Role of Multiple Cycles |

|---|---|---|

| Infiltration | Liquid fills pores/cracks | Introduces new material to voids |

| Pyrolysis | Mass loss & gas release | Converts polymer to solid SiC |

| Shrinkage | Volume reduction | Creates new gaps for next cycle |

| Final Result | Matrix densification | Eliminates porosity for strength |

Elevate Your Ceramic Matrix Composites with KINTEK

Achieve unmatched structural integrity in your PIP processing. Backed by expert R&D and precision manufacturing, KINTEK offers specialized Pyrolysis, Vacuum, and CVD systems designed to handle the rigorous demands of iterative SiC heat treatments. Whether you need customizable lab high-temp furnaces or industrial-scale solutions, we provide the thermal precision required to minimize micro-cracks and maximize density. Contact KINTEK today to discover how our advanced furnace technology can optimize your production efficiency and material performance.

Visual Guide

References

- Katsumi Yoshida, Masaki Kotani. Mechanical properties of SiC <sub>f</sub> /SiC composites with h‐BN interphase formed by the electrophoretic deposition method. DOI: 10.1111/ijac.14687

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of vacuum brazing in modern manufacturing? Achieve Strong, Pure Joints for Critical Applications

- Why is a de-oiling pre-treatment step required in magnesium sublimation? To Ensure High-Purity Recovery

- How is a directional solidification furnace used to remove metallic impurities from silicon? Achieve Solar-Grade Purity

- In what way does a Spark Plasma Sintering (SPS) system inhibit grain growth? Achieve Precision Nanostructures

- What is the process of furnace brazing? Achieve Clean, Strong Metal Joining Without Flux

- Why are vacuum and modified atmosphere furnaces essential for 3D printing? Unlock Dense, Strong Parts with Controlled Sintering

- What is the objective of vacuum drying in NaF–Na3AlF6 electrolytes? Ensure High-Purity Molten Salt Performance

- How does graphite's thermal conductivity improve vacuum furnace performance? Achieve Superior Thermal Uniformity