In modern manufacturing, the significance of vacuum brazing lies in its unique ability to create exceptionally strong, pure, and uniform joints in a highly controlled environment. By performing the joining process in a vacuum, it eliminates the oxidation and contamination that plague other methods, making it indispensable for producing mission-critical components in sectors like aerospace, medical, and automotive.

The core challenge in high-performance metal joining is preventing atmospheric contamination, which weakens bonds. Vacuum brazing solves this fundamentally by removing the atmosphere itself, resulting in flawless, flux-free joints that are impossible to achieve otherwise.

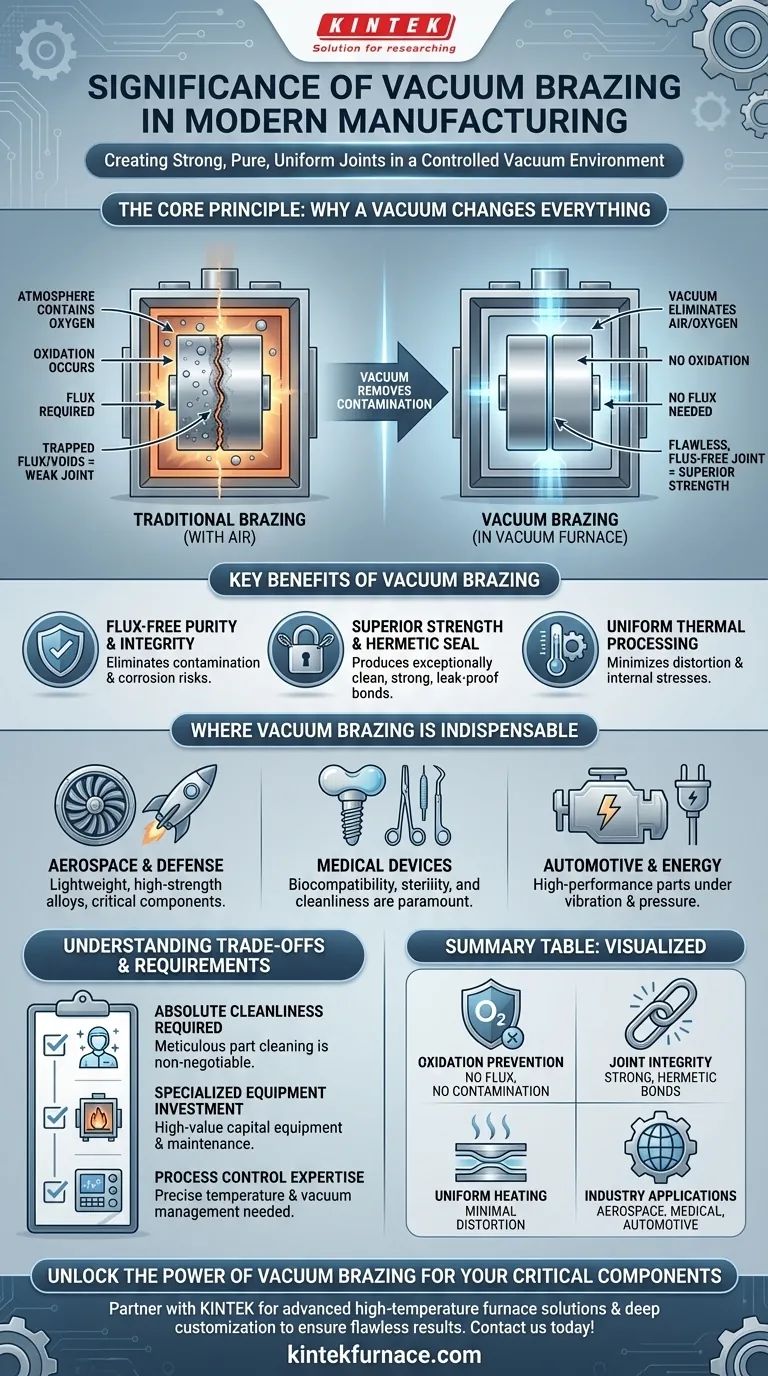

The Core Principle: Why a Vacuum Changes Everything

Vacuum brazing is a high-temperature joining process where parts are heated in a vacuum furnace. A filler metal with a lower melting point flows between the closely fitted surfaces of the parts, creating a metallurgical bond upon cooling. The vacuum environment is the key differentiator.

Eliminating Oxidation Without Flux

The primary role of the vacuum is to remove oxygen and other reactive gases. This prevents the formation of oxides on the metal surfaces during heating.

Oxide layers act as barriers that inhibit the filler metal from properly wetting and bonding with the base materials. Traditional brazing uses a chemical agent called flux to dissolve these oxides, but flux can become trapped in the joint, causing corrosion or structural weak points.

Vacuum brazing makes flux entirely unnecessary, resulting in a cleaner and more reliable bond.

Achieving Superior Joint Integrity and Purity

By eliminating the risk of oxidation and flux entrapment, vacuum brazing produces joints that are exceptionally clean, strong, and hermetically sealed.

This level of purity is non-negotiable in applications like medical implants, where any residue could be harmful, or in aerospace components, where a microscopic flaw could lead to catastrophic failure.

Ensuring Uniform Thermal Processing

A vacuum furnace provides an incredibly stable and uniform heating environment. The parts are heated and cooled in a highly controlled cycle.

This uniform thermal processing minimizes internal stresses, distortion, and warping, which is especially critical when joining complex assemblies or delicate materials. The result is a dimensionally stable final product.

Where Vacuum Brazing is Indispensable

The unique benefits of vacuum brazing make it the go-to process for industries where performance and reliability are paramount.

Aerospace and Defense: For Strength and Low Weight

In aerospace, every gram matters. Vacuum brazing is used to join lightweight, high-strength alloys and complex geometries, such as turbine blades and heat exchangers. The process creates joints that are as strong as the parent materials, ensuring structural integrity under extreme conditions of temperature and pressure.

Medical Devices: For Biocompatibility and Sterility

For surgical instruments, diagnostic equipment, and permanent implants, cleanliness is a matter of patient safety. Vacuum brazing creates perfectly smooth, pure, and void-free joints with no flux residue. This ensures the final device is biocompatible and can be effectively sterilized.

Automotive and Energy: For Performance Under Stress

High-performance automotive parts like fuel injectors and transmission components must withstand constant vibration and high pressure. Vacuum brazing produces leak-proof, durable joints that ensure long-term reliability and efficiency in these demanding applications.

Understanding the Trade-offs and Requirements

While powerful, vacuum brazing is a specialized process with specific demands that make it unsuitable for every application.

The Need for Absolute Cleanliness

Vacuum brazing is unforgiving of contaminants. The parts to be joined must be meticulously cleaned before entering the furnace, as any oils, greases, or particulates will vaporize in the vacuum and interfere with the process. This often requires dedicated clean-room assembly environments.

The Investment in Specialized Equipment

Vacuum furnaces are complex and expensive pieces of capital equipment. The high initial investment and ongoing maintenance costs mean the process is typically reserved for high-value components where the benefits of superior joint quality justify the expense.

Process Control and Expertise

Successfully executing a vacuum braze cycle requires deep technical expertise. Operators must precisely control variables like temperature ramp rates, hold times, and vacuum levels. Developing a repeatable process for a new assembly is a significant engineering effort.

Is Vacuum Brazing Right for Your Application?

Choosing a joining method requires balancing technical requirements with production realities. Use these guidelines to determine if vacuum brazing fits your goal.

- If your primary focus is mission-critical reliability: Vacuum brazing is often the default choice for applications in aerospace or high-pressure systems due to its unmatched joint integrity.

- If your primary focus is biocompatibility or purity: The fluxless, contaminant-free nature of the process makes it the ideal solution for medical devices or components for the semiconductor industry.

- If your primary focus is cost-sensitive mass production: You must weigh the high equipment and process costs against the quality gains; less complex furnace brazing or other joining methods may be more appropriate.

Ultimately, vacuum brazing is an enabling technology, allowing engineers to design and build components that simply could not exist otherwise.

Summary Table:

| Aspect | Significance |

|---|---|

| Oxidation Prevention | Eliminates need for flux, preventing contamination and corrosion in joints. |

| Joint Integrity | Produces strong, hermetically sealed bonds ideal for high-stress environments. |

| Uniform Heating | Ensures minimal distortion and internal stresses for dimensional stability. |

| Industry Applications | Essential for aerospace, medical devices, and automotive components requiring reliability. |

Unlock the Power of Vacuum Brazing for Your Critical Components

Are you designing for aerospace, medical, or automotive applications where joint purity and strength are non-negotiable? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored to meet your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to ensure flawless, flux-free brazing results. Don't let contamination compromise your products—contact us today to discuss how our expertise can enhance your manufacturing process and deliver reliable, high-performance joints!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions