At its core, furnace brazing is a high-precision metal joining process where components are heated in a controlled atmosphere. A filler metal with a lower melting point than the base materials is used, which melts and is drawn into the joint by capillary action, creating a strong, clean, metallurgical bond upon cooling.

The critical insight is that furnace brazing is not just a heating process; it's an environmental control process. By using a vacuum or protective atmosphere, it eliminates oxidation and the need for flux, enabling the creation of exceptionally clean, strong, and leak-tight joints in complex assemblies.

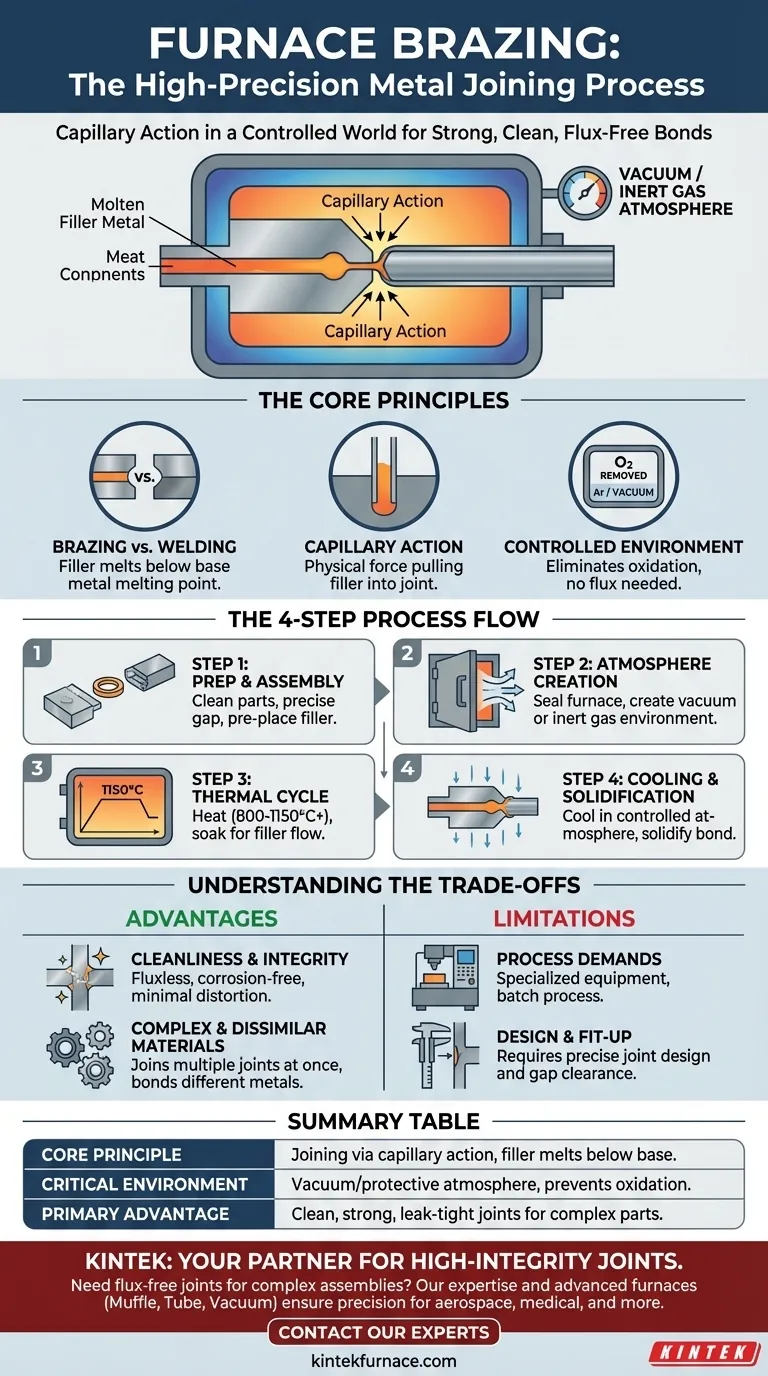

The Core Principle: Capillary Action in a Controlled World

To understand furnace brazing, you must grasp three interlocking concepts: the nature of brazing itself, the physical force that makes it work, and the environment that allows for perfection.

What is Brazing?

Brazing joins metals by melting a filler metal into the gap between two components. Crucially, the process temperature is high enough to melt the filler but always below the melting point of the base metals being joined. This distinguishes it from welding, where the base metals themselves are melted and fused together.

The Role of Capillary Action

Capillary action is the physical force that pulls the molten filler metal into the tight-fitting joint. Just as water is drawn up into a narrow straw, the liquid filler is naturally pulled through the small, uniform gap between the parts, ensuring a complete and consistent bond throughout the joint.

The Critical "Furnace" Environment

The furnace provides a controlled atmosphere, which is the key to this method's success. This is typically a vacuum or a protective gas like argon. This environment prevents the formation of oxides on the metal surfaces during heating, which would otherwise inhibit the flow of the filler metal and weaken the final bond.

The Step-by-Step Furnace Brazing Process

The furnace brazing cycle is a precise sequence of events designed to produce a perfect metallurgical bond between components. Each step is critical to the final outcome.

Step 1: Joint Preparation and Assembly

Parts must be thoroughly cleaned and assembled with the filler metal pre-placed at or near the joint. The gap between the components is carefully engineered to be extremely small, allowing capillary action to function correctly.

Step 2: Creating the Controlled Atmosphere

The entire assembly is loaded into a furnace, which is then sealed. All air is removed to create a high-level vacuum, or the chamber is flooded with an inert gas. This step removes oxygen and other contaminants that could compromise the joint.

Step 3: The Thermal Cycle

The furnace slowly heats the assembly to the specified brazing temperature, which can range from 800°C to 1150°C or higher. The assembly is held at this temperature—a phase known as "soaking"—for a short period to ensure the filler metal is fully molten and has flowed throughout the entire joint.

Step 4: Solidification and Cooling

After soaking, the assembly is cooled in a controlled manner, still within the vacuum or protective atmosphere. As it cools, the filler metal solidifies, forming a strong, permanent metallurgical bond with the surfaces of the base materials. Air is only allowed back into the furnace once the part has cooled sufficiently.

Understanding the Trade-offs

Furnace brazing offers significant advantages, but it's essential to recognize its specific requirements and limitations to determine if it is the right choice for your application.

Advantage: Unmatched Joint Integrity and Cleanliness

Because the process is fluxless and occurs in a vacuum, the resulting joints are exceptionally clean and free of contaminants or residual flux that can cause corrosion. The uniform heating also minimizes thermal stress and distortion.

Advantage: Joining Complex and Dissimilar Materials

Furnace brazing is ideal for intricate assemblies with multiple joints, as all bonds can be made simultaneously. The lower process temperatures also make it effective for joining dissimilar metals that would be difficult or impossible to weld.

Limitation: Process and Equipment Demands

This method requires specialized and expensive equipment, namely a vacuum or controlled atmosphere furnace. It is a batch process, which may be less efficient for single, simple parts compared to manual joining methods.

Limitation: Design and Fit-up are Non-Negotiable

The success of furnace brazing is entirely dependent on the correct joint design. The gap clearance must be tightly controlled to facilitate capillary action. Poor fit-up will result in an incomplete or weak bond.

Making the Right Choice for Your Goal

Selecting furnace brazing depends entirely on the specific requirements of your component and its application.

- If your primary focus is joining complex, multi-joint assemblies: Furnace brazing allows you to create all bonds simultaneously with minimal distortion.

- If your primary focus is creating high-purity, leak-tight seals: The flux-free, controlled atmosphere of furnace brazing is ideal for sensitive applications in aerospace, medical, and vacuum systems.

- If your primary focus is joining delicate, thin-walled, or dissimilar materials: The uniform heating and lower temperatures prevent the warping and metallurgical issues associated with welding.

By controlling the entire environment, furnace brazing delivers a level of precision, cleanliness, and integrity that many other joining methods cannot match.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Joining metals using a filler metal melted below the base metals' melting point via capillary action. |

| Critical Environment | Vacuum or protective atmosphere (e.g., argon) to prevent oxidation, eliminating the need for flux. |

| Typical Temperature Range | 800°C to 1150°C+ |

| Primary Advantage | Creates exceptionally clean, strong, and leak-tight joints in complex or dissimilar materials. |

| Key Consideration | Requires precise joint design and gap clearance for capillary action to work effectively. |

Need to create high-integrity, flux-free joints for your complex assemblies?

At KINTEK, we understand that precision and cleanliness are paramount. Our furnace brazing expertise, backed by advanced R&D and manufacturing, ensures your components achieve the strong, leak-tight bonds required for demanding applications in aerospace, medical, and vacuum systems.

We offer a range of high-temperature laboratory furnaces, including Muffle, Tube, Rotary, and Vacuum systems, all customizable to meet your unique brazing process requirements.

Contact our experts today to discuss how our solutions can enhance your metal joining capabilities.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas