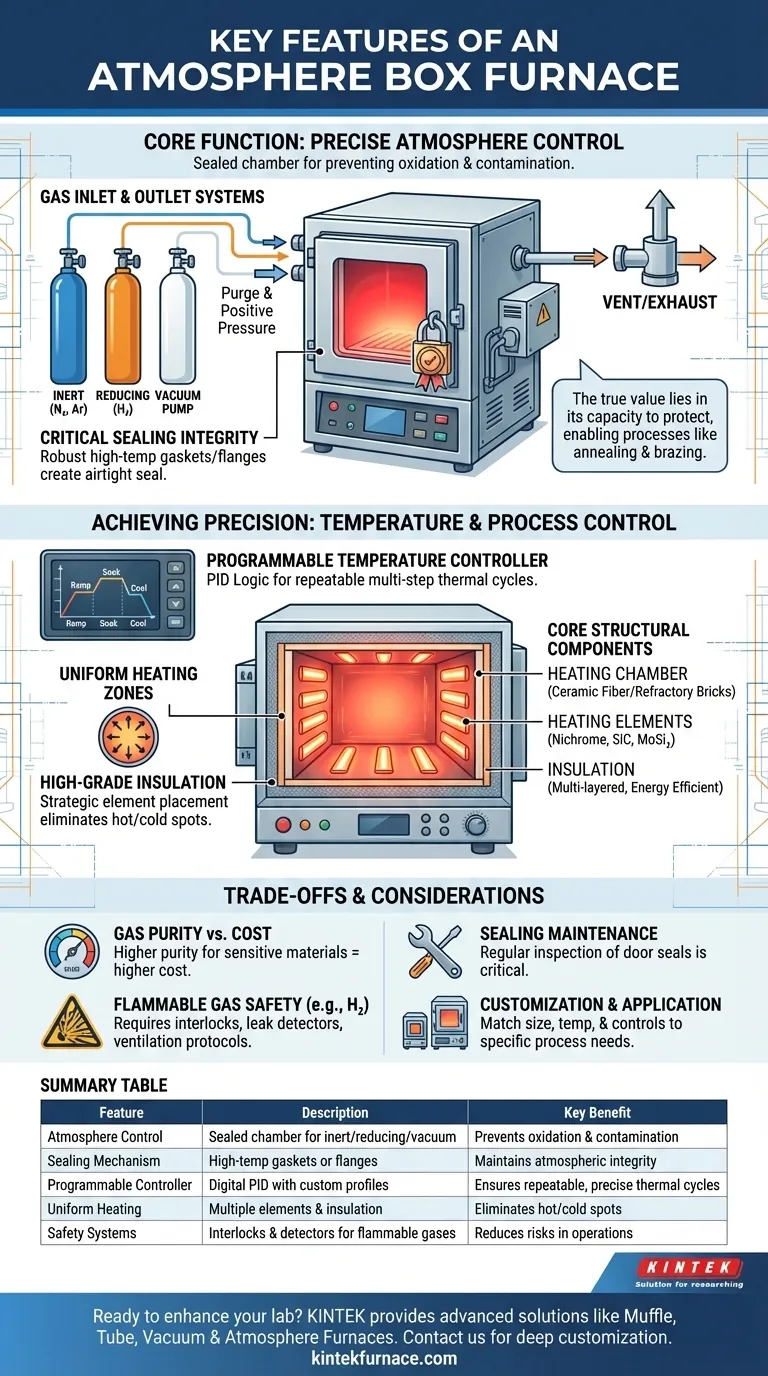

At its core, an atmosphere box furnace is engineered for one primary purpose: to precisely control the gaseous environment surrounding a material during high-temperature processing. Unlike a standard furnace that heats in ambient air, its defining feature is a sealed chamber that allows for the introduction of specific gases—or the creation of a vacuum—to prevent oxidation, contamination, and other unwanted chemical reactions.

The true value of an atmosphere box furnace lies not just in its ability to heat, but in its capacity to protect. It creates a chemically stable environment at high temperatures, enabling processes like annealing, sintering, or brazing that are impossible in open air.

The Foundation: Atmosphere Control and Integrity

The central function of this equipment is to replace the reactive ambient air with a controlled, predictable environment. This capability is built upon several interconnected features.

The Purpose of Atmosphere Control

A controlled atmosphere prevents unwanted chemical reactions on a material's surface at elevated temperatures. The most common goal is to prevent oxidation (rusting or scaling) by displacing oxygen.

This is achieved using different types of gases:

- Inert Gases: Nitrogen (N₂) and Argon (Ar) are used to create a non-reactive environment for processes like annealing and brazing.

- Reducing Gases: A hydrogen (H₂) mixture can be used to actively remove oxygen from a material's surface, a process known as reduction.

- Vacuum: Removing all gases from the chamber provides the purest environment, though it adds complexity and cost.

Gas Inlet and Outlet Systems

The furnace includes dedicated ports and flow controllers to manage the gas environment. The system purges the chamber of air before heating begins and maintains a slight positive pressure during operation to ensure any leaks flow outward, not inward.

The Critical Role of Sealing

To maintain the integrity of the controlled atmosphere, the furnace door and any access ports must have a robust sealing mechanism. High-temperature silicone gaskets or precisely machined metal flanges are used to create an airtight seal, preventing contamination from outside air.

Achieving Precision: Temperature and Process Control

Consistent, repeatable results depend on more than just the atmosphere; they require exacting control over the thermal cycle.

Programmable Temperature Controllers

Modern atmosphere furnaces feature advanced digital controllers (often using PID logic) that allow users to program specific temperature profiles. This enables multi-step processes with controlled ramp rates, soaking times at specific temperatures, and controlled cooling.

Uniform Heating Zones

To ensure every part of a component receives the same thermal treatment, high-quality furnaces are designed for superior temperature uniformity. This is achieved through the strategic placement of multiple heating elements and high-grade insulation, eliminating hot or cold spots within the chamber.

Core Structural Components

The furnace's performance and longevity are determined by its physical construction. Key components include:

- Heating Chamber: Often built from high-purity ceramic fiber or refractory bricks that can withstand extreme temperatures while remaining chemically inert.

- Heating Elements: These generate the heat and are chosen based on the furnace's maximum temperature. Common types include Nichrome wire, Silicon Carbide (SiC), or Molybdenum Disilicide (MoSi₂).

- Insulation: Multi-layered insulation minimizes heat loss, which improves energy efficiency and temperature stability.

Understanding the Trade-offs and Limitations

While powerful, an atmosphere furnace introduces complexities and requires careful consideration of its operational trade-offs.

Gas Purity vs. Cost

The purity of the process gas directly impacts the quality of the final product. While standard industrial-grade nitrogen is sufficient for many applications, high-purity gases are significantly more expensive but necessary for sensitive materials.

Flammable Gases and Safety

Using reducing gases like hydrogen introduces a significant safety risk. Furnaces designed for hydrogen must include mandatory safety interlocks, leak detectors, and specific ventilation protocols, which increases the equipment's cost and complexity.

Sealing Integrity and Maintenance

The door seal is a critical wear item. It requires regular inspection and periodic replacement to prevent leaks that would compromise the atmospheric integrity and ruin the process.

Customization and Application

There is no one-size-fits-all model. The furnace's maximum temperature, chamber size, and control systems must be specified to match the intended application, whether for small-scale research or larger production needs.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the material process you need to perform.

- If your primary focus is preventing oxidation (e.g., bright annealing): Prioritize a furnace with excellent sealing integrity and precise flow control for inert gases like Nitrogen or Argon.

- If your primary focus is material purification or deoxidation: You must select a furnace explicitly designed to handle reducing gases like hydrogen, equipped with all necessary safety systems.

- If your primary focus is process repeatability for production: Invest in a model with an advanced programmable controller and documented temperature uniformity across the heating chamber.

Ultimately, choosing an atmosphere furnace is about matching its specific control features to the chemical and thermal demands of your material process.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Atmosphere Control | Sealed chamber for inert/reducing gases or vacuum | Prevents oxidation and contamination |

| Sealing Mechanism | High-temperature gaskets or metal flanges | Maintains atmospheric integrity |

| Programmable Controller | Digital PID with custom temperature profiles | Ensures repeatable, precise thermal cycles |

| Uniform Heating | Multiple elements and insulation for even heat | Eliminates hot/cold spots |

| Safety Systems | Interlocks and detectors for flammable gases | Reduces risks in operations |

Ready to enhance your lab's capabilities with a tailored atmosphere box furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization ensures precise fit for your unique experimental needs—contact us today to discuss how we can optimize your high-temperature processes! Get in touch now

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation