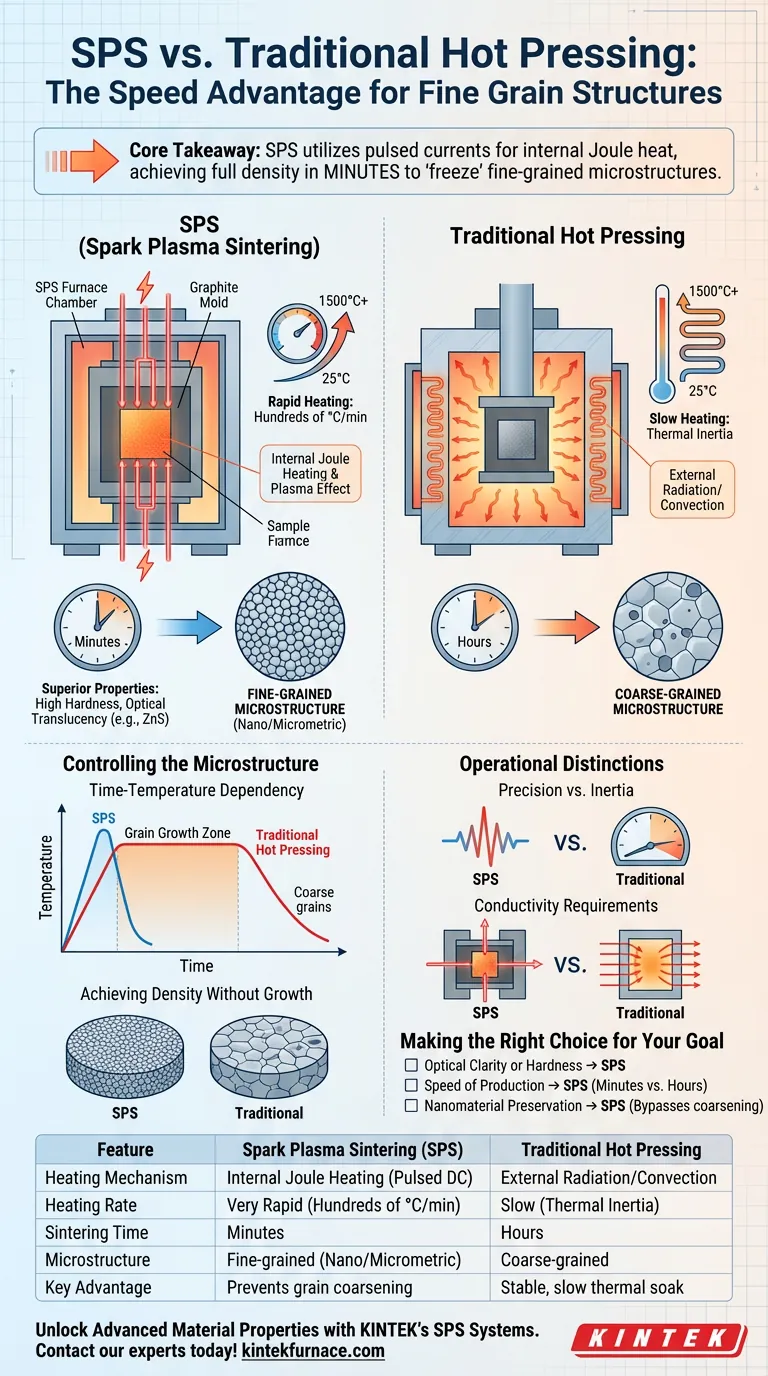

Spark Plasma Sintering (SPS) inhibits grain growth primarily through speed. Unlike traditional hot pressing, which relies on slow external heating, SPS utilizes pulsed electric currents to generate heat directly within the mold and sample. This allows for extremely rapid heating rates and short holding times, enabling the material to fully densify before the grains have the time required to coarsen.

Core Takeaway By utilizing pulsed currents to generate internal Joule heat, SPS bypasses the thermal inertia of traditional furnaces. This "high-temperature, short-time" capability allows materials to reach full density in minutes, effectively "freezing" the microstructure in a fine-grained nanometric or micrometric state.

The Mechanism of Rapid Heating

Internal Joule Heating

Traditional sintering furnaces rely on external heating elements. Heat must travel via radiation and convection to the mold surface, and then slowly conduct into the sample.

In contrast, an SPS system passes a pulsed DC current directly through the graphite mold and, depending on conductivity, the sample itself. This generates significant Joule heat internally, bypassing the need for external heat transfer.

Bypassing Thermal Inertia

Because the heat is generated internally, the system is not slowed down by the thermal inertia of a large furnace chamber.

This mechanism enables heating rates of several hundred degrees per minute. The system reaches the target sintering temperature almost immediately compared to the slow ramp-up required by hot pressing.

The Plasma Effect

The primary mechanism is supported by the "plasma effect" induced by the pulsed currents. This phenomenon contributes to the rapid heating technology and surface activation of the particles.

This effect aids in the rapid consolidation of the material, further accelerating the densification process.

Controlling the Microstructure

The Time-Temperature Dependency

Grain growth is fundamentally a diffusion process that depends heavily on both temperature and time. In traditional methods, the long dwell times required for heat to penetrate the sample provide ample opportunity for grains to merge and grow larger (coarsening).

Freezing the Grain Structure

SPS radically alters the time variable in this equation. Because the heating is so rapid, the material spends minimal time in the specific temperature zones where grain coarsening typically occurs.

Achieving Density Without Growth

The process completes densification in an extremely short duration. This allows the production of ceramics or intermetallic compounds that are fully dense but retain a fine-grained structure at the nanometer or micrometer scale.

As evidenced in materials like Zinc Sulfide (ZnS), this results in superior properties, such as high hardness and excellent optical translucency, which are often compromised by coarse grains.

Operational Distinctions

Precision vs. Inertia

While traditional hot pressing offers a stable, slow thermal soak, SPS relies on dynamic, high-energy pulses. The trade-off is that the process is much faster and requires precise control of the current and pressure to prevent overheating or uneven densification given the speed of the reaction.

Conductivity Requirements

Because the process relies on passing current through the mold (and often the sample), the setup is distinct from radiation-based heating. The generation of Joule heat is directly tied to the electrical path, making the interaction between the pulsed current and the tooling a critical factor in success.

Making the Right Choice for Your Goal

When deciding between SPS and traditional methods, consider the specific properties required for your final application.

- If your primary focus is Optical Clarity or Hardness: SPS is the superior choice, as it inhibits grain growth to maintain the fine microstructure necessary for high translucency and mechanical strength.

- If your primary focus is Speed of Production: SPS offers a significant advantage by bypassing thermal inertia, reducing cycle times from hours to minutes.

- If your primary focus is Nanomaterial Preservation: The rapid thermal cycle of SPS is essential to prevent the inevitable coarsening that occurs during the long heat-soak of traditional furnaces.

By leveraging the physics of pulsed current heating, SPS decouples densification from grain growth, allowing you to achieve material properties that are impossible with conventional thermal cycles.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Hot Pressing |

|---|---|---|

| Heating Mechanism | Internal Joule Heating (Pulsed DC) | External Radiation/Convection |

| Heating Rate | Very Rapid (Hundreds of °C/min) | Slow (Thermal Inertia) |

| Sintering Time | Minutes | Hours |

| Microstructure | Fine-grained (Nano/Micrometric) | Coarse-grained |

| Key Advantage | Prevents grain coarsening | Stable, slow thermal soak |

Unlock Advanced Material Properties with KINTEK

Maintaining a fine-grained microstructure is critical for superior hardness, optical clarity, and mechanical strength. KINTEK’s advanced Spark Plasma Sintering (SPS) systems leverage rapid internal Joule heating to bypass thermal inertia, allowing you to reach full density in minutes while effectively "freezing" your material's nanostructure.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of lab solutions, including:

- Customizable Muffle, Tube, and Rotary Furnaces

- High-Performance Vacuum and CVD Systems

- Precision Sintering Equipment tailored to your unique research needs

Ready to transform your material processing? Contact our experts today to find the perfect high-temp solution!

Visual Guide

References

- Akhtar Ali, Hijaz Ahmad. Narrowing of band gap and decrease in dielectric loss in La1-xSrxMnO3 for x = 0.0, 0.1, and 0.2 manganite nanoparticles. DOI: 10.3389/fmats.2024.1369122

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the objective of using a high-temperature carbonization furnace for hard carbon synthesis? Optimize Performance

- What are the environmental requirements for vacuum sintering? Achieve Superior Material Density and Purity

- Why use a vacuum diffusion annealing furnace for Zircaloy-4? Ensure Uniformity & Prevent Oxidation

- What role does a vacuum drying oven play in the preparation of anhydrous calcium chloride? Ensuring High-Purity Results

- What benefits does a vacuum quenching furnace provide in tool manufacturing? Achieve Superior Hardness and Precision

- What are the maintenance requirements for a vacuum furnace when not in use? Protect Your Investment with Proper Storage

- What role does a floating zone furnace play in high-purity superconducting growth? Achieve Crucible-Free Excellence

- What are the selection criteria for vacuum pumps in vacuum furnaces? Optimize for Purity and Efficiency