To properly maintain a vacuum furnace when not in use, you must protect its internal environment from atmospheric contamination. The two primary methods are to either keep the chamber under a constant low vacuum or to backfill it with a pure, dry inert gas like nitrogen. This prevents moisture from being absorbed by the furnace's internal components, which is the principal cause of degradation and performance issues during downtime.

The core challenge of idle furnace maintenance is fighting moisture and air. A vacuum furnace is designed to be a pristine, controlled environment; leaving it open to the atmosphere invites contamination that significantly increases future cycle times and can damage sensitive internal materials.

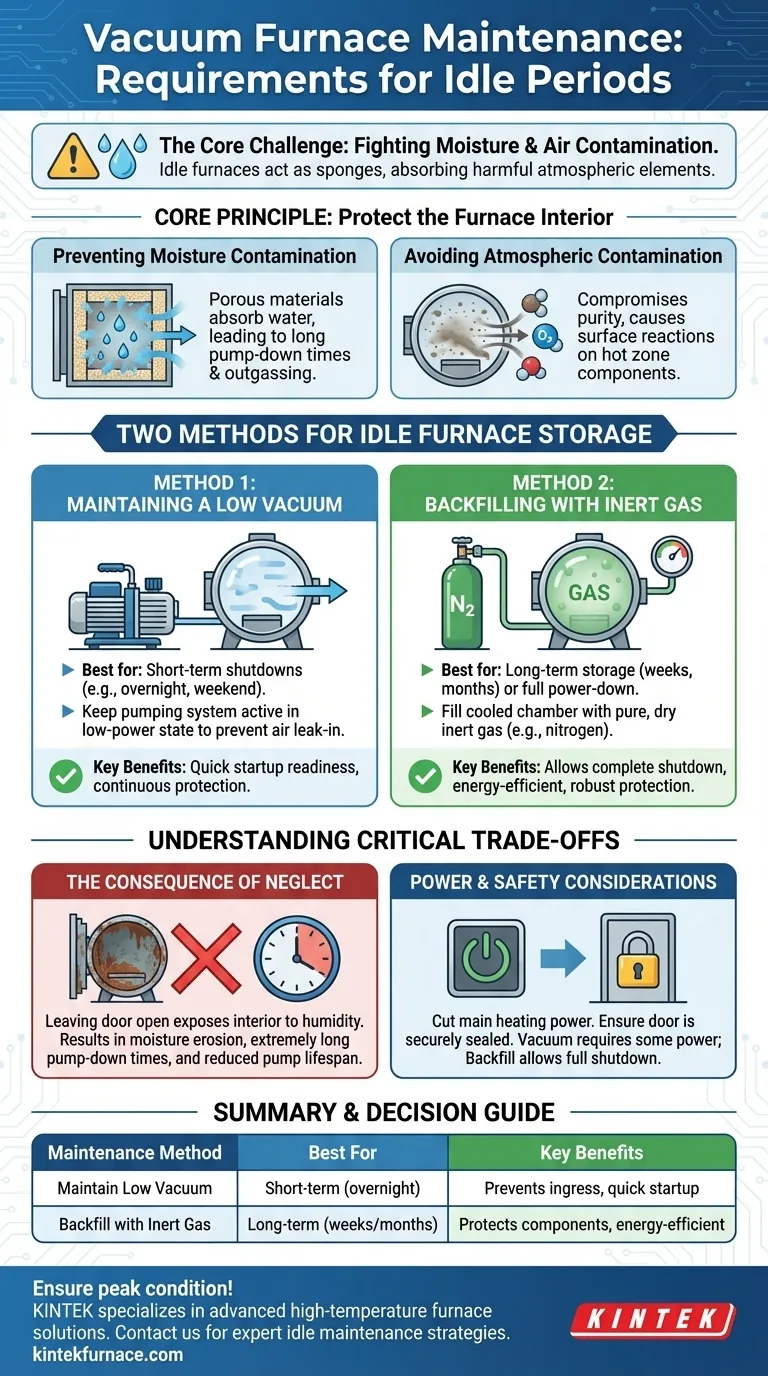

The Core Principle: Protecting the Furnace Interior

A vacuum furnace's performance is entirely dependent on the quality of its internal environment. When idle, the primary goal is to prevent the degradation of this environment.

Preventing Moisture Contamination

Moisture is the single greatest enemy of an idle vacuum furnace. The internal refractory materials and graphite insulation are porous and will act like sponges, absorbing water vapor from the ambient air.

This absorbed moisture leads to significant problems on your next run, including dramatically longer pump-down times and outgassing that can contaminate the workpiece.

Avoiding Atmospheric Contamination

Beyond water, atmospheric air contains oxygen, dust, and other contaminants. Allowing these to enter the chamber can compromise the purity required for high-performance processes and can lead to unwanted surface reactions on the furnace's hot zone components over time.

Two Methods for Idle Furnace Storage

Your strategy should be to create a barrier that prevents ambient air from entering the chamber. There are two standard industry practices for achieving this.

Method 1: Maintaining a Low Vacuum

The most common method, especially for short-term shutdowns, is to leave the furnace under a rough or low vacuum.

By keeping the pumping system active in a low-power or intermittent state, you ensure the pressure inside the chamber is always lower than the outside atmosphere. This physically prevents air and moisture from leaking in.

Method 2: Backfilling with Inert Gas

For longer-term storage or when you wish to power down the pumping system completely, backfilling is the ideal solution.

After the furnace has cooled, the chamber is filled with a high-purity, dry inert gas, typically nitrogen. Maintaining a slight positive pressure ensures that if any minor leaks exist, the clean gas will leak out rather than contaminated air leaking in.

Understanding the Critical Trade-offs

Failing to properly secure an idle furnace is not a minor oversight; it has direct consequences on operational efficiency and equipment longevity.

The Consequence of Neglect

Simply shutting down the furnace and leaving the door unsealed or open is the worst-case scenario. This directly exposes the insulation and refractory materials to humidity.

The result is moisture erosion and saturation, leading to extremely long pump-down times on the next startup as you must pump out all the absorbed water vapor. This wastes energy, time, and reduces the lifespan of your pump.

Power and Safety Considerations

When shutting down, the main heating power supply must be cut off for safety. The door should always be securely closed and sealed to create the initial barrier.

Whether you cut power to the pumping and control systems depends on your chosen idle strategy. Maintaining a vacuum requires some power, while a nitrogen backfill allows for a more complete shutdown. Always follow specific manufacturer guidelines.

Making the Right Choice for Your Operation

Your idle maintenance strategy should align with your operational tempo and the duration of the downtime.

- If your furnace will be idle for a short period (e.g., overnight or a weekend): Maintaining a low vacuum is often the most practical and efficient method to ensure it's ready for a quick startup.

- If your furnace is being shut down for long-term storage (e.g., weeks or months): Performing a full cooldown and then backfilling the chamber with positive-pressure nitrogen is the most robust and energy-efficient solution.

- If you are prioritizing equipment longevity above all: Never leave the chamber open to atmosphere for any longer than is absolutely necessary for loading and unloading.

Proper idle maintenance is a direct investment in the reliability and performance of your vacuum furnace.

Summary Table:

| Maintenance Method | Best For | Key Benefits |

|---|---|---|

| Maintain Low Vacuum | Short-term idle periods (e.g., overnight) | Prevents air/moisture ingress, quick startup readiness |

| Backfill with Inert Gas | Long-term storage (e.g., weeks or months) | Protects components, allows full power shutdown, energy-efficient |

Ensure your vacuum furnace stays in peak condition during downtime! KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, with deep customization to meet your unique needs. Our expert team can help you implement the best idle maintenance strategies for reliability and efficiency. Contact us today to learn more and protect your investment!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control