In tool manufacturing, a vacuum quenching furnace provides the critical benefits of significantly improved hardness and wear resistance while simultaneously reducing part deformation and eliminating surface decarburization. This controlled process ensures that high-performance materials like tool steels achieve their maximum potential without compromising the dimensional accuracy required for precision components.

The core value of vacuum quenching is its ability to resolve the fundamental conflict in heat treatment: achieving extreme hardness through rapid cooling without sacrificing the precise geometry and surface integrity of the finished tool.

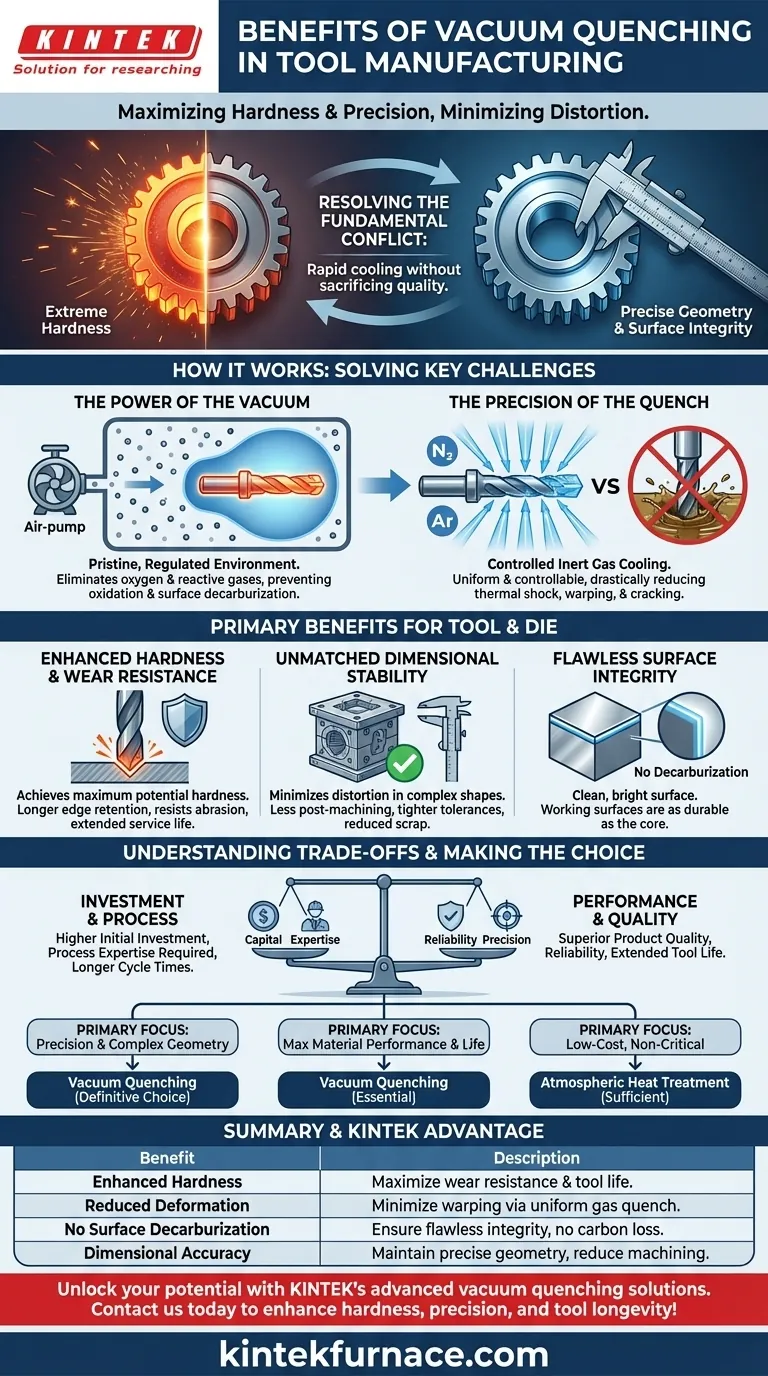

How Vacuum Quenching Solves Key Tooling Challenges

Traditional heat treatment methods expose hot metal to oxygen, leading to surface defects, and their less-controlled cooling can cause parts to warp. A vacuum quenching furnace addresses these issues by creating a pristine, highly regulated environment for the entire process.

The Power of the Vacuum

A vacuum furnace begins by removing the atmosphere from its heating chamber. This seemingly simple step is fundamental to the quality of the final tool.

By eliminating oxygen and other reactive gases, the process completely prevents oxidation and surface decarburization—the loss of carbon from the steel's surface. This ensures the tool's entire working surface retains its intended hardness and chemical composition.

The Precision of the Quench

After heating the tool to its critical austenitizing temperature in the vacuum, the furnace rapidly introduces a high-pressure inert gas (like nitrogen or argon) to cool it. This is the "quench."

This method of gas quenching is significantly more uniform and controllable than plunging a hot tool into oil or water. The controlled, even cooling drastically reduces thermal shock and internal stresses, which are the primary causes of warping, distortion, and cracking.

The Primary Benefits for Tool & Die Manufacturing

For manufacturers of molds, dies, and cutting tools, these process advantages translate directly into superior product quality and reliability.

Enhanced Hardness and Wear Resistance

The rapid, controlled quench allows materials like high-speed steel and die steel to achieve their maximum potential hardness. This results in tools that hold a sharp edge longer, resist abrasion, and have a significantly extended service life.

Unmatched Dimensional Stability

By minimizing thermal shock, vacuum quenching produces tools with exceptional dimensional accuracy. For complex molds and dies with intricate features and tight tolerances, this means less post-treatment machining or grinding, saving time and reducing scrap rates.

Flawless Surface Integrity

Because the process occurs in a vacuum, the finished tool emerges from the furnace clean and bright, with no surface decarburization. The cutting edges and working surfaces are as hard and durable as the core material, which is critical for performance and longevity.

Understanding the Trade-offs

While vacuum quenching offers superior results, it is important to understand its position relative to other heat treatment methods.

Higher Initial Investment

Vacuum furnaces are complex, sophisticated pieces of equipment that represent a significant capital investment compared to conventional atmospheric furnaces.

Process Expertise Required

Achieving optimal results requires precise control over the entire cycle, including heating rates, vacuum levels, and quenching pressures. This demands a higher level of operator skill and process knowledge to tailor cycles for different materials and geometries.

Longer Cycle Times

The process of pulling a vacuum, heating, soaking, and gas quenching can sometimes take longer than older, less precise methods. This can be a factor in high-volume production planning.

Making the Right Choice for Your Goal

The decision to use vacuum quenching depends on the performance demands of the final product.

- If your primary focus is precision and complex geometry: Vacuum quenching is the definitive choice, as its ability to minimize distortion is unmatched.

- If your primary focus is maximum material performance and tool life: Vacuum quenching is essential for eliminating surface flaws and achieving the highest possible hardness and wear resistance.

- If your primary focus is low-cost, non-critical components: Simpler atmospheric heat treatments may be sufficient where dimensional accuracy and surface perfection are less important.

Ultimately, adopting vacuum quenching is an investment in quality and reliability, ensuring that your tools perform exactly as they were designed.

Summary Table:

| Benefit | Description |

|---|---|

| Enhanced Hardness | Achieves maximum material hardness for improved wear resistance and longer tool life. |

| Reduced Deformation | Minimizes warping and distortion through controlled, uniform gas quenching. |

| No Surface Decarburization | Prevents loss of carbon from the surface, ensuring flawless integrity in oxygen-free environments. |

| Dimensional Accuracy | Maintains precise geometry, reducing the need for post-treatment machining. |

Unlock the full potential of your tool manufacturing with KINTEK's advanced vacuum quenching solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Vacuum & Atmosphere Furnaces, complemented by deep customization to meet your unique experimental needs. Contact us today to enhance hardness, precision, and tool longevity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing