High-temperature MEMS pressure sensors depend on vacuum encapsulation to maintain accuracy and reliability in extreme environments. This design choice primarily serves to establish a stable absolute pressure reference, while simultaneously neutralizing the physical interference caused by gas damping and thermal convection.

In high-heat environments, internal gases can expand and disrupt sensitive measurements. Vacuum encapsulation eliminates these variables, preventing non-linear errors and ensuring the sensor provides a pure, stable signal regardless of external thermal conditions.

The Mechanics of Stability in Extreme Heat

To understand why vacuum encapsulation is non-negotiable for high-temperature MEMS, you must look at how heat interacts with gases.

Establishing a Stable Reference

For a pressure sensor to be accurate, it needs a consistent baseline to measure against.

A vacuum cavity provides a stable absolute pressure reference. Unlike a gas-filled cavity, which would fluctuate significantly with temperature changes, a vacuum remains constant. This ensures the sensor’s baseline "zero" does not drift as the environment heats up.

Eliminating Thermal Convection

Temperature gradients within a sensor can cause internal gases to move, a process known as convection.

This movement transfers heat unevenly and creates physical noise on the sensing element. By removing the air (creating a vacuum), engineers eliminate thermal convection interference. This isolation ensures that the temperature of the sensing element remains stable and predictable.

Enhancing Measurement Accuracy

Beyond thermal management, the vacuum environment directly improves the mechanical performance of the MEMS structure.

Reducing Gas Damping Effects

In a standard environment, the microscopic moving parts of a MEMS sensor encounter resistance from air molecules.

This phenomenon, known as gas damping, significantly affects the sensor's dynamic response. Vacuum encapsulation removes these molecules, allowing the capacitive sensor to move freely without fluid resistance. This results in a sharper, more accurate response to pressure changes.

Preventing Non-Linear Errors

One of the greatest threats to accuracy at high temperatures is the expansion of internal gases.

As temperature rises, any gas trapped inside the sensor cavity will expand, exerting unwanted pressure on the sensing diaphragm. This causes non-linear errors that distort the reading. Vacuum encapsulation removes the internal gas entirely, ensuring signal purity by preventing this expansion from ever occurring.

Understanding the Trade-offs

While vacuum encapsulation is superior for performance, it introduces specific engineering challenges that must be acknowledged.

Manufacturing Complexity

Achieving and maintaining a high-quality vacuum at the micro-scale adds significant complexity to the fabrication process.

This requirement often increases the cost and time required to manufacture these sensors compared to non-vacuum variants.

Vulnerability to Leakage

The reliability of the sensor is entirely dependent on the integrity of the vacuum seal.

If the hermetic seal is compromised—even slightly—by thermal stress or physical shock, the vacuum is lost. This leads to immediate "leakage" errors and a complete loss of the absolute pressure reference.

Making the Right Choice for Your Goal

When selecting or designing pressure sensors for high-temperature applications, consider your specific constraints.

- If your primary focus is absolute accuracy: Prioritize sensors with high-grade vacuum encapsulation to ensure a drift-free reference point.

- If your primary focus is signal stability: Ensure the vacuum quality is sufficient to fully eliminate gas damping and thermal noise.

Vacuum encapsulation is not just a feature; it is the fundamental barrier standing between a precise measurement and thermal chaos.

Summary Table:

| Feature | Impact of Vacuum Encapsulation | Benefit in High-Temp Applications |

|---|---|---|

| Pressure Reference | Establishes a stable absolute zero baseline | Prevents baseline drift during temperature fluctuations |

| Thermal Convection | Eliminates internal gas movement | Ensures stable temperature and predictable sensing element behavior |

| Gas Damping | Removes air molecule resistance | Enhances dynamic response and sensor sensitivity |

| Internal Gas Expansion | Prevents pressure from expanding gases | Eliminates non-linear measurement errors and preserves signal purity |

Elevate Your Sensor Performance with KINTEK

Precise thermal management is the foundation of high-performance electronics and material science. At KINTEK, we understand that stability in extreme environments is non-negotiable.

Backed by expert R&D and world-class manufacturing, we provide high-precision thermal processing solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are developing advanced MEMS or testing materials for extreme heat, our systems are fully customizable to meet your unique research and production needs.

Ready to achieve thermal stability? Contact us today to consult with our experts and discover how KINTEK can enhance your lab's precision and efficiency.

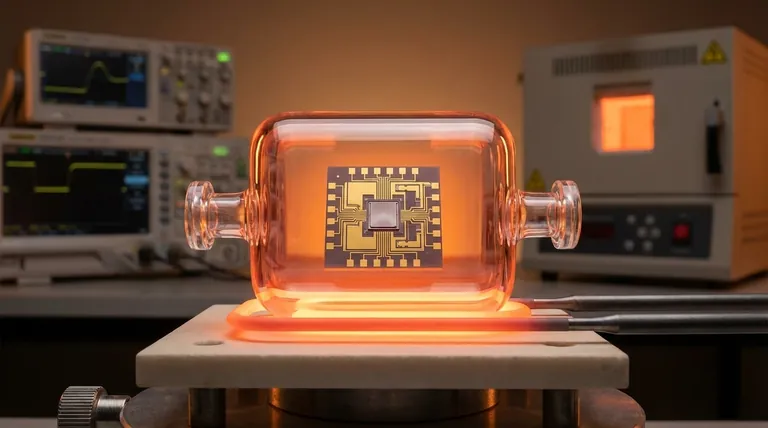

Visual Guide

References

- MEMS Pressure Sensor for High-Temperature Applications. DOI: 10.18260/1-2--53829

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum pyrolysis furnace in lunar ceramic 3D printing? High-Precision Debinding Solutions

- What are the advantages of vacuum furnaces over traditional furnaces? Achieve Superior Purity and Control

- What are the space-saving benefits of a vertical vacuum furnace? Maximize Efficiency in Compact Labs

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- How does a vacuum furnace prevent oxidation of the workpiece? Achieve Purity and Precision in High-Temp Processing

- How do vacuum furnaces ensure clean and bright surfaces on materials? Achieve Purity and Precision in Thermal Processing

- Why must NaF and KF raw materials be processed in a vacuum oven for FUNaK synthesis? Ensure Purity and Safety

- What role do vacuum furnaces play in the semiconductor industry? Essential for High-Purity Processing and Yield