Without question, a vertical vacuum furnace is one of the most effective ways to minimize floor space usage in a modern manufacturing or laboratory facility. Its fundamental design stacks components vertically rather than spreading them out horizontally, directly reducing the required square footage. This vertical orientation also unlocks unique workflow efficiencies by allowing you to use the space directly beneath the furnace for staging and loading operations.

A vertical furnace's primary advantage is not just its smaller footprint, but its ability to transform how you use the entire volumetric space of your facility, enabling unique workflow and material handling efficiencies.

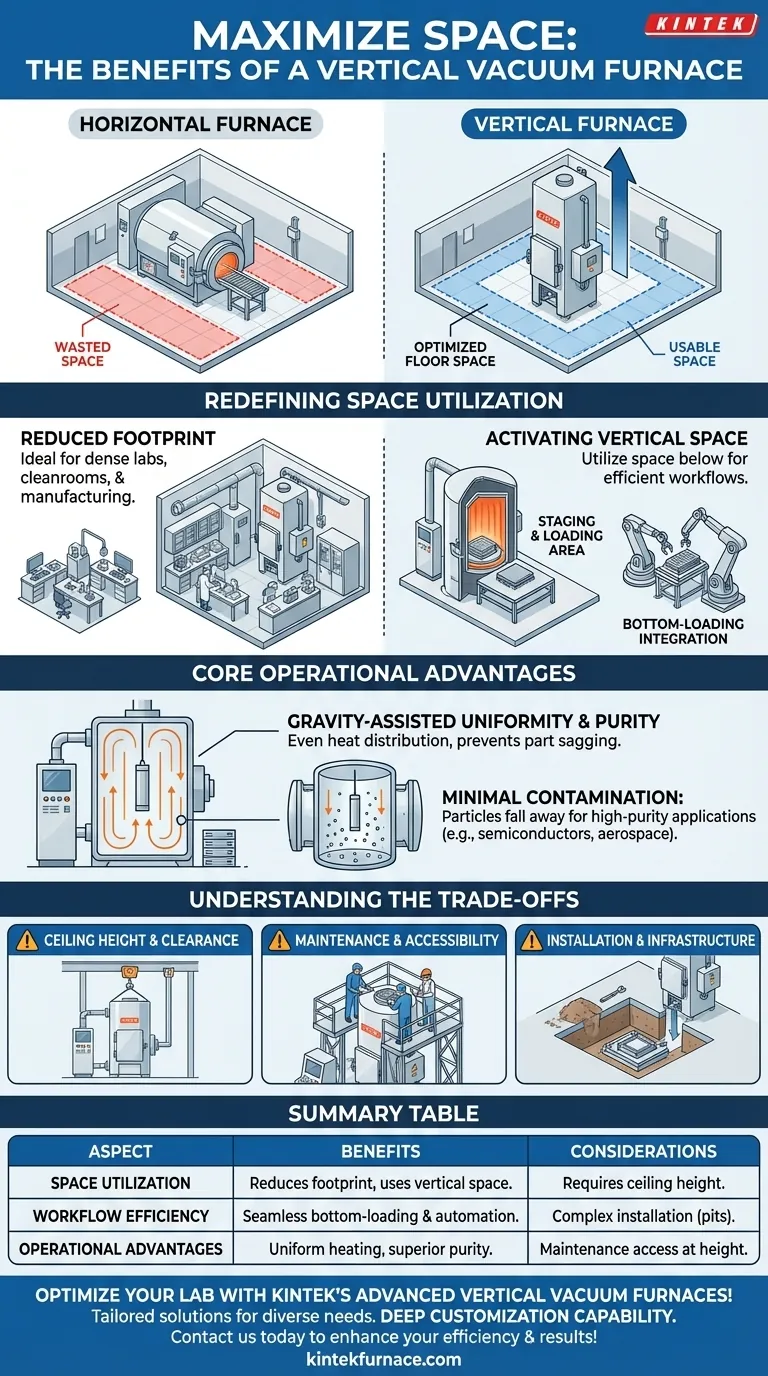

How Vertical Furnaces Redefine Space Utilization

Understanding the spatial benefits of a vertical furnace requires looking beyond the simple floor plan. It involves rethinking the use of a facility's three-dimensional space.

The Obvious Benefit: A Reduced Footprint

The most direct advantage is the significant reduction in occupied floor space. By orienting the heating chamber, pumping systems, and controls vertically, the furnace's footprint can be a fraction of a comparable horizontal model.

This makes it an ideal solution for dense manufacturing floors, cleanrooms, or research labs where every square foot of space is at a premium.

The Hidden Benefit: Activating Vertical Space

A key, often overlooked, benefit is the ability to use the physical space under the furnace. Most vertical furnaces are bottom-loading, meaning the workload is lifted from below into the heating chamber.

This design allows for staging areas or automated transfer systems to be located directly beneath the furnace, creating a highly efficient and compact work cell. Loads can be prepared and queued without occupying adjacent floor space.

Impact on Workflow and Material Handling

The vertical loading process naturally integrates with modern automation. For industries like semiconductor manufacturing, automated wafer and boat transfer systems can seamlessly lift materials into the furnace.

This vertical motion can be simpler and more reliable than the long horizontal insertion required by other furnace types, improving productivity and reducing handling errors.

Beyond Space: Core Operational Advantages

While the space savings are compelling, the vertical design also delivers critical performance benefits that are directly tied to its orientation.

The Role of Gravity in Process Uniformity

Gravity becomes an ally in a vertical furnace. It helps ensure even heat distribution as convection currents flow naturally. For certain parts, hanging them vertically can prevent the sagging, warping, or distortion that might occur when they are laid flat at high temperatures.

Superior Purity and Contamination Control

The vertical orientation provides an inherent advantage in cleanliness. Any microscopic particles generated during the process are more likely to fall straight down due to gravity, away from the product being treated.

This results in minimal particle generation on the material itself, a critical factor for high-purity applications like medical implants, aerospace components, and electronics.

Unlocking High-Performance Material Properties

Like all vacuum furnaces, vertical models provide an impurity-free, controlled environment. This allows for superior heat treatment that enhances material properties like strength, density, and surface finish.

This precision is essential for processing reactive and advanced metals such as tungsten, molybdenum, and titanium.

Understanding the Trade-offs

No design is without its considerations. An objective evaluation must include the potential constraints of a vertical system.

Ceiling Height and Overhead Clearance

The most significant trade-off is the need for vertical space. You are trading horizontal floor space for vertical clearance. You must account for the full height of the furnace itself, plus the additional overhead room required for lifting mechanisms and maintenance access.

Maintenance and Accessibility

Servicing a vertically stacked system can be more complex than working on a horizontal unit. Technicians may require ladders or elevated platforms to access components at the top of the furnace, which can impact maintenance time and logistics.

Installation and Infrastructure

The installation of a vertical furnace, particularly a large one, often requires a pit or specialized foundation to accommodate the bottom-loading mechanism. This can add complexity and cost to the initial setup compared to a freestanding horizontal furnace.

Making the Right Choice for Your Application

Your decision should be driven by a clear understanding of your primary operational goal.

- If your primary focus is maximizing floor space in a constrained facility: A vertical furnace is the superior choice, provided you have adequate ceiling height.

- If your primary focus is processing high-purity materials (like semiconductors): The vertical design offers inherent advantages in minimizing particle contamination due to gravity.

- If your primary focus is process consistency for specific part geometries: Gravity-assisted heating in a vertical furnace can prevent part distortion and improve thermal uniformity.

- If your primary focus is minimizing initial cost and simplifying maintenance: A traditional horizontal furnace may be a more straightforward option, assuming you have the floor space to accommodate it.

Ultimately, selecting a vertical furnace is a strategic decision to optimize not just your floor plan, but your entire production process.

Summary Table:

| Aspect | Benefits |

|---|---|

| Space Utilization | Reduces footprint, activates vertical space for staging and loading |

| Workflow Efficiency | Enables bottom-loading, integrates with automation for seamless operations |

| Operational Advantages | Gravity aids in uniform heating, minimizes contamination, enhances material properties |

| Key Considerations | Requires ceiling height, may need pits for installation, maintenance can be complex |

Optimize your lab's space and performance with KINTEK's advanced vertical vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our high-temperature furnace solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?