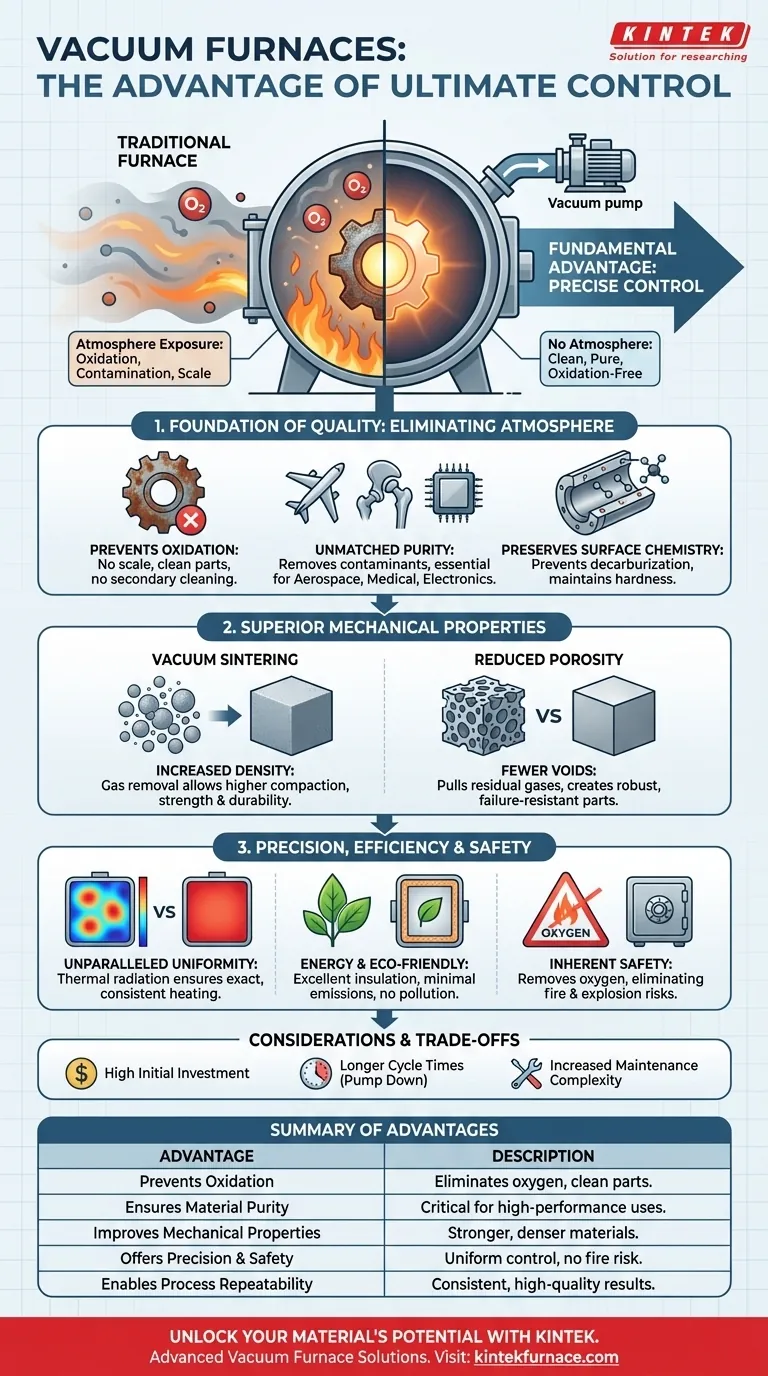

The fundamental advantage of a vacuum furnace is control. By removing the atmosphere from the heating process, you gain precise control over the material's environment, resulting in superior purity, enhanced mechanical properties, and unparalleled process repeatability. This level of control is simply unattainable in traditional furnaces where the material is constantly exposed to reactive gases like oxygen.

The core principle is straightforward: removing air eliminates the root cause of oxidation, contamination, and atmospheric interference. A vacuum furnace doesn't just heat a material; it creates an ultra-clean environment that allows the material to achieve its maximum theoretical purity and strength.

Eliminating the Atmosphere: The Foundation of Quality

The most significant benefits of a vacuum furnace stem directly from operating in a near-total absence of air and its associated gases.

Preventing Oxidation and Contamination

In a traditional furnace, the oxygen in the air reacts with hot metal surfaces, creating an oxide layer (scale). This process degrades the surface finish and can compromise the part's integrity.

A vacuum furnace physically removes the oxygen before heating begins. This prevents oxidation entirely, resulting in clean, bright parts that often require no secondary cleaning operations.

Achieving Unmatched Material Purity

Beyond oxygen, the atmosphere contains moisture and other potential contaminants. A vacuum environment evacuates these elements, ensuring the final product is free from impurities.

This is critical for high-performance applications in aerospace, medical implants, and electronics, where even microscopic contamination can lead to catastrophic failure.

Preserving Surface Chemistry

Heating certain alloys, like steel, in an atmosphere can cause decarburization—a process where carbon is stripped from the material's surface, making it softer and weaker.

The controlled environment of a vacuum furnace prevents this reaction, ensuring the material retains its intended hardness and wear resistance across its entire structure.

Superior Mechanical and Structural Properties

By controlling the environment, vacuum furnaces enable processes that produce mechanically superior materials.

Increasing Material Density

Processes like vacuum sintering and vacuum hot pressing are used to consolidate powdered materials into solid parts.

The vacuum helps remove trapped gases between the powder particles, allowing the material to compact to a much higher density. This directly translates to increased strength and durability.

Reducing Porosity

Porosity, or the presence of tiny voids within a material, is a primary cause of mechanical weakness and failure.

By operating in a vacuum, you can effectively pull residual gases out of the material as it is heated and densified, significantly reducing internal porosity and creating a more robust final part.

Precision, Efficiency, and Safety by Design

The design of a vacuum furnace inherently provides advantages in process control, operational efficiency, and workplace safety.

Unparalleled Temperature Uniformity

In a traditional furnace, air currents create hot and cold spots, leading to inconsistent heating. A vacuum furnace primarily uses thermal radiation for heating in a still environment.

This, combined with advanced PID temperature controllers, allows for exceptionally precise and uniform temperature distribution across the entire workload, ensuring every part receives the exact same thermal treatment.

Energy Efficiency and Environmental Benefits

While vacuum pumps require energy, the overall process is often more efficient. The vacuum acts as an excellent insulator, reducing heat loss to the outside.

Furthermore, because no protective combustion gases are needed, vacuum furnaces produce minimal emissions and no pollution, making them a far more environmentally friendly technology.

Inherent Process Safety

Perhaps one of the most overlooked benefits is safety. By removing oxygen—a key component of the fire triangle—the risk of fire or explosion is virtually eliminated.

This is a stark contrast to many atmosphere furnaces, which may use flammable gases like hydrogen to prevent oxidation, introducing significant safety hazards.

Understanding the Trade-offs and Considerations

While powerful, vacuum furnaces are not the solution for every application. Their advantages come with specific trade-offs.

Higher Initial Investment

Vacuum furnaces are complex systems involving sealed chambers, high-capacity pumps, and sophisticated control systems. This results in a significantly higher upfront capital cost compared to most conventional furnaces.

Potentially Longer Cycle Times

The process of pumping down the chamber to the required vacuum level adds time to the beginning of every cycle. For applications where speed is more critical than ultimate quality, this can be a drawback.

Increased Maintenance Complexity

The vacuum pumps, seals, and advanced instrumentation require specialized knowledge for maintenance and troubleshooting. This can lead to higher long-term service costs compared to simpler atmospheric units.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your project's specific goals for quality, cost, and material performance.

- If your primary focus is maximum material purity and performance: A vacuum furnace is non-negotiable for critical applications in aerospace, medical, or advanced research where material integrity is paramount.

- If your primary focus is high-volume, lower-cost heat treatment: A traditional atmosphere furnace may be more cost-effective if minor surface oxidation is acceptable or can be easily removed in a secondary step.

- If your primary focus is process repeatability and tight specifications: The precise control of temperature and atmosphere in a vacuum furnace provides a decisive advantage for achieving consistent, high-quality production.

- If your primary focus is environmental impact and operator safety: The pollution-free, fire-safe operation of vacuum furnaces makes them a superior choice for modern, responsible manufacturing.

Ultimately, choosing a vacuum furnace is an investment in a level of process control that unlocks new possibilities for material performance.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation | Eliminates oxygen to avoid surface scale and contamination, resulting in clean parts without secondary cleaning. |

| Ensures Material Purity | Removes moisture and contaminants, critical for high-performance uses in aerospace, medical implants, and electronics. |

| Improves Mechanical Properties | Increases density and reduces porosity through processes like vacuum sintering for stronger, more durable materials. |

| Offers Precision and Safety | Provides uniform temperature control, energy efficiency, and eliminates fire risks by removing oxygen from the environment. |

| Enables Process Repeatability | Delivers consistent results with advanced controls, ideal for applications requiring tight specifications. |

Unlock the full potential of your materials with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing purity, safety, and efficiency. Ready to elevate your processes? Contact us today to discuss how our tailored solutions can benefit your aerospace, medical, or electronics projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today