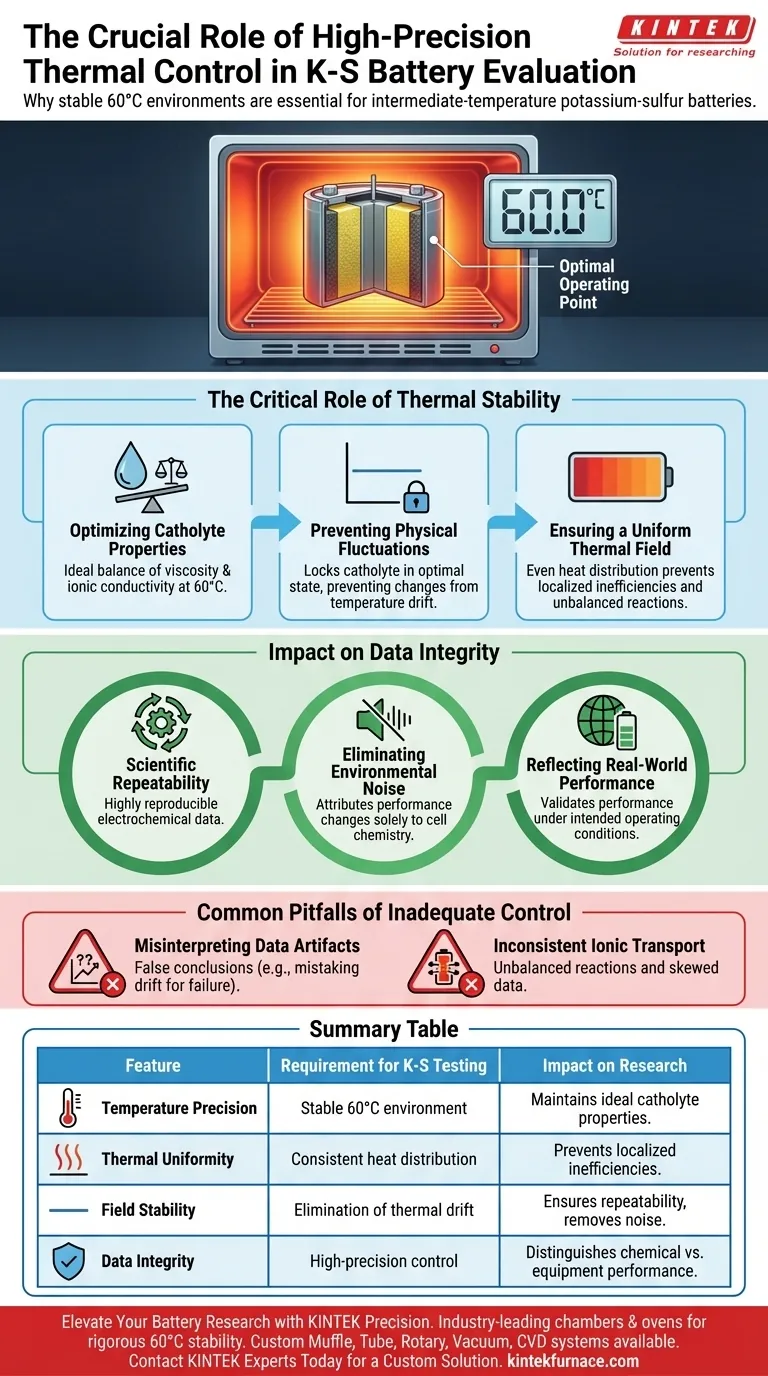

Precise thermal management is the baseline requirement for evaluating intermediate-temperature potassium-sulfur batteries. High-precision constant temperature drying ovens or environmental test chambers are strictly required to create a stable, uniform thermal field at the specific operating point of 60 degrees Celsius. Without this equipment, you cannot maintain the ideal viscosity and ionic conductivity of the catholyte, which renders resulting performance data unreliable.

Intermediate-temperature potassium-sulfur batteries rely on specific electrolyte behaviors that are optimized at a steady 60°C. High-precision equipment eliminates thermal variables, ensuring that observed performance metrics reflect the battery's chemistry rather than environmental fluctuations.

The Critical Role of Thermal Stability

Optimizing Catholyte Properties

The electrochemical performance of these batteries is heavily dependent on the physical state of the catholyte. At the intended operating temperature of 60 degrees Celsius, the catholyte achieves the ideal balance of viscosity and ionic conductivity.

Preventing Physical Fluctuations

If the temperature deviates even slightly, the viscosity of the fluid can change. This directly impacts how easily ions move through the system. High-precision chambers prevent these fluctuations, locking the catholyte in its optimal state for the duration of the test.

Ensuring a Uniform Thermal Field

It is not enough to simply heat the air around the battery; the heat must be distributed evenly. High-precision equipment provides a uniform thermal field, ensuring that every part of the battery cell experiences the exact same temperature, preventing localized inefficiencies.

The Impact on Data Integrity

Achieving Scientific Repeatability

In battery research, data is only valuable if it can be reproduced. Maintaining a strictly stable environment ensures that the electrochemical data collected is highly repeatable.

Eliminating Environmental Noise

When temperature control is precise, you remove the "noise" of environmental variables. This allows you to attribute changes in battery performance solely to the cell's internal chemistry, rather than external temperature shifts.

Reflecting Real-World Performance

Testing must mimic the intended use case to be valid. Precise chambers ensure the data accurately reflects battery performance under its intended operating conditions, providing a realistic baseline for future development.

Common Pitfalls of Inadequate Control

Misinterpreting Data Artifacts

Using standard ovens with high thermal variance can lead to false conclusions. You may interpret a drop in conductivity as a battery failure mechanism, when it is actually a symptom of the oven temperature drifting below 60°C.

Inconsistent Ionic Transport

If the thermal field is not uniform, different parts of the cell may conduct ions at different rates. This leads to unbalanced reactions within the cell, producing skewed data that does not represent the true potential of the potassium-sulfur chemistry.

Ensuring Validity in Battery Research

To ensure your data is robust and defensible, consider your specific testing goals:

- If your primary focus is electrolyte characterization: Use high-precision thermal chambers to isolate viscosity and conductivity variables, ensuring they are influenced only by chemistry, not temperature drift.

- If your primary focus is long-term cycle life: Prioritize equipment with exceptional stability to guarantee that data collected over weeks or months remains repeatable and comparable.

By rigorously controlling the thermal environment, you transform your test results from rough estimates into definitive, reproducible science.

Summary Table:

| Feature | Requirement for K-S Testing | Impact on Research |

|---|---|---|

| Temperature Precision | Stable 60°C environment | Maintains ideal catholyte viscosity and ionic conductivity |

| Thermal Uniformity | Consistent heat distribution | Prevents localized inefficiencies and unbalanced cell reactions |

| Field Stability | Elimination of thermal drift | Ensures scientific repeatability and removes environmental noise |

| Data Integrity | High-precision control | Distinguishes chemical performance from equipment fluctuations |

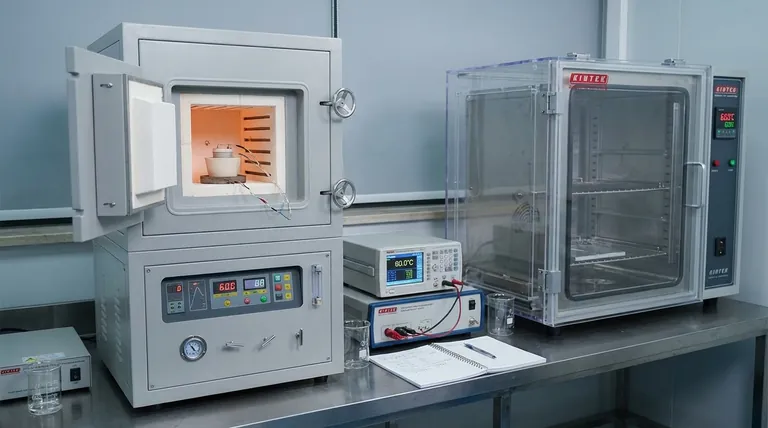

Elevate Your Battery Research with KINTEK Precision

Don't let thermal instability compromise your breakthrough data. KINTEK provides industry-leading high-precision environmental chambers and drying ovens designed to maintain the rigorous 60°C stability required for potassium-sulfur battery evaluation.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique lab high-temp needs. Ensure your data reflects your chemistry, not your equipment.

Contact KINTEK Experts Today for a Custom Solution

Visual Guide

References

- Liying Tian, Zhichuan J. Xu. Dual Roles of Deep Eutectic Solvent in Polysulfide Redox and Catalysis for Intermediate‐Temperature Potassium‐Sulfur Batteries. DOI: 10.1002/adma.202507114

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does microstructural observation assist in optimizing LATP sintering? Master High-Density Material Processing

- Why are high-energy laser beams and precision control systems necessary for PBF? Master Ceramic Fabrication

- How do h-BN targets improve memristor switching ratios? Maximize Logic Windows with High-Purity Precursors

- What role does an arc-imaging furnace play in NaMgPO4:Eu synthesis? Rapid Phase Discovery & Olivine Isolation

- What is the purpose of adding calcium fluoride (CaF2) in magnesium production? Accelerate Your Vacuum Carbothermal Reduction

- Why specific constant temperature holding times for NbC and Cr7C3? Achieve Stoichiometric Precision in Lab Synthesis

- What is the role of high-temperature calcination equipment in Waste Tire Charcoal preparation? Master WTC Pyrolysis

- What are the advantages of using a vacuum drying oven for BiVO4/COF composite photoanodes? Preserve Material Integrity