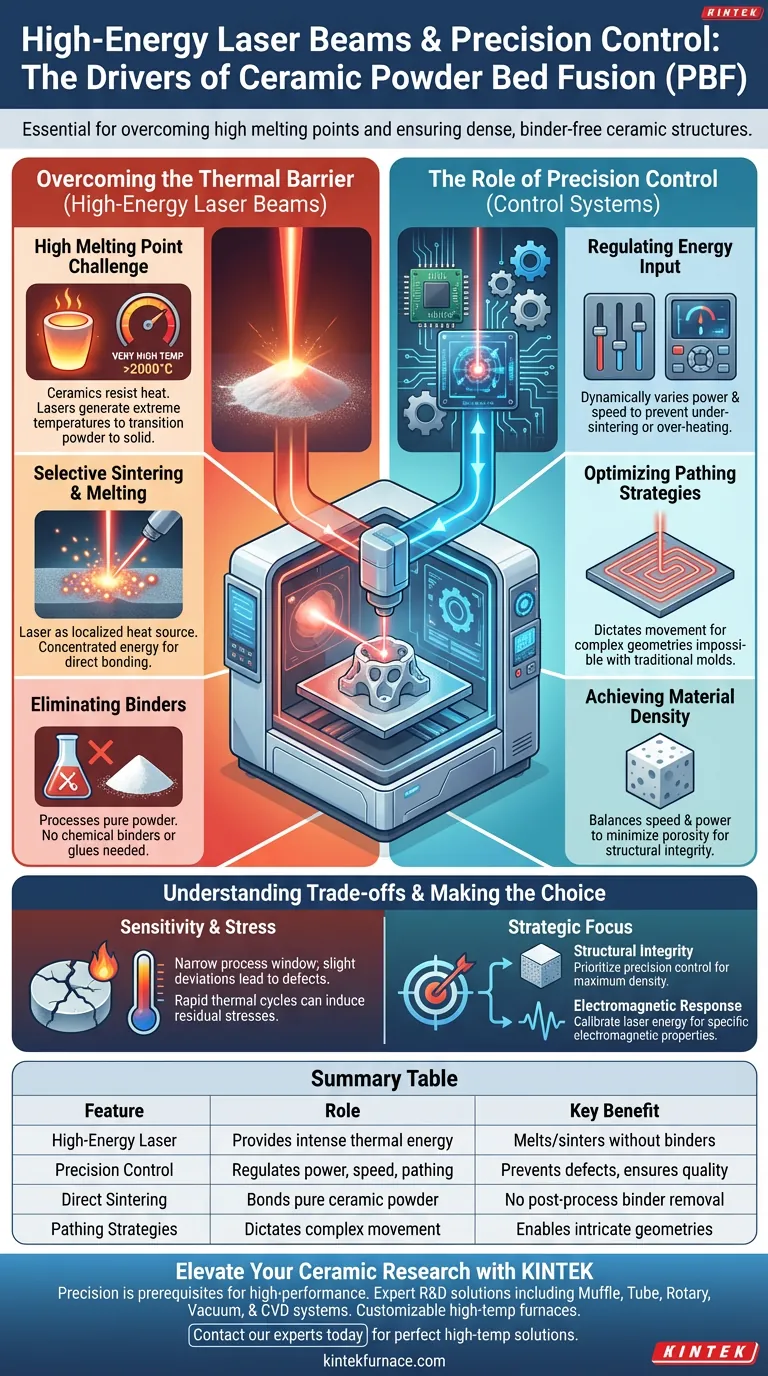

High-energy laser beams and precision control systems are the fundamental drivers of the Powder Bed Fusion (PBF) process for ceramics. The lasers provide the intense thermal energy required to melt or sinter ceramic materials—which inherently possess extremely high melting points—while the control systems meticulously regulate that energy to bond particles without the need for chemical binders.

Ceramics present unique thermal challenges compared to metals or polymers. PBF utilizes focused laser energy to overcome these high melting thresholds, while digital control systems ensure the creation of dense, binder-free structures capable of delivering specific electromagnetic performance.

Overcoming the Thermal Barrier

The High Melting Point Challenge

Ceramics are defined by their resistance to heat, possessing melting points far higher than traditional manufacturing materials. High-energy laser beams are necessary to generate the extreme temperatures required to transition ceramic powder from solid particles into a cohesive mass.

Selective Sintering and Melting

The laser acts as a localized heat source that selectively scans the powder bed. By concentrating high energy into a specific focal point, the system facilitates the direct bonding of ceramic particles.

Eliminating the Need for Binders

A critical advantage of using high-energy lasers is the ability to process pure ceramic powder. Because the laser provides sufficient energy for direct sintering, the process eliminates the need for binders or glues typically used to hold ceramic particles together in other fabrication methods.

The Role of Precision Control

Regulating Energy Input

Raw power is insufficient without management; precision control systems differ the laser's output to match the specific material requirements. These systems dynamically regulate laser power and scanning speed to prevent under-sintering (weak parts) or over-heating (material degradation).

Optimizing Pathing Strategies

The control system dictates the laser’s movement across the powder bed. Precise pathing allows for the fabrication of complex geometries that would be impossible with traditional molds.

Achieving Material Density

The ultimate goal of this control is to create a dense structure. By carefully balancing speed and power, the system minimizes porosity, ensuring the final component has the structural integrity required for functional use.

Understanding the Trade-offs

Sensitivity to Process Parameters

The window for success in ceramic PBF is extremely narrow. Slight deviations in laser power or scan speed can lead to significant defects, such as cracking or delamination, due to the brittle nature of ceramics.

Thermal Stress Management

While high energy is necessary, it introduces steep thermal gradients. The rapid heating and cooling cycles controlled by the system can induce residual stresses within the part, requiring careful calibration to avoid warping.

Making the Right Choice for Your Goal

To maximize the effectiveness of PBF for ceramics, align your process controls with your specific performance targets:

- If your primary focus is Structural Integrity: Prioritize precision control over scanning speed to ensure maximum density and particle bonding.

- If your primary focus is Electromagnetic Response: Calibrate the laser energy to achieve the specific density and microstructure required to tune the material's electromagnetic properties.

Precision in energy delivery is not just a feature; it is the prerequisite for high-performance ceramic fabrication.

Summary Table:

| Feature | Role in Ceramic PBF | Key Benefit |

|---|---|---|

| High-Energy Laser | Provides intense localized thermal energy | Melts/sinters ceramics without chemical binders |

| Precision Control | Regulates power, speed, and scan pathing | Prevents material degradation and structural defects |

| Direct Sintering | Bonds pure ceramic powder directly | Eliminates the need for post-process binder removal |

| Pathing Strategies | Dictates complex laser movement | Enables intricate geometries impossible with molds |

Elevate Your Ceramic Research with KINTEK

Precision in energy delivery is the prerequisite for high-performance ceramic fabrication. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are developing advanced materials or optimizing PBF parameters, our lab high-temp furnaces are fully customizable to meet your unique thermal processing needs.

Ready to achieve superior material density and structural integrity? Contact our experts today to find the perfect high-temperature solution for your lab!

Visual Guide

References

- Wenqing Wang, Rujie He. Advanced 3D printing accelerates electromagnetic wave absorption from ceramic materials to structures. DOI: 10.1038/s44334-024-00013-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why must the filling of the working medium into a sodium heat pipe be performed inside a protective glovebox?

- What is the purpose of using a laboratory blast drying oven at 107°C for 17 hours for reforming catalysts?

- How is a vacuum impregnation system utilized during wood leaching resistance tests? Achieve Full Saturation for EN 84

- What is the purpose of performing homogenization at 1250°C? Optimizing Sintered Cobalt-Based Superalloys

- Why is a high-temperature annealing process in a vacuum oven required for CMSMs? Unlock Membrane Precision

- What is the purpose of using high-purity argon gas for NAB alloys? Ensure Superior Nickel-Aluminum Bronze Integrity

- What is the function of an industrial drying oven in ZnZrOx catalyst prep? Ensure Uniform Metal Precursor Adsorption

- What is the primary process objective of using an electric furnace in glass experiments? Analyze Stress & Heat Transfer