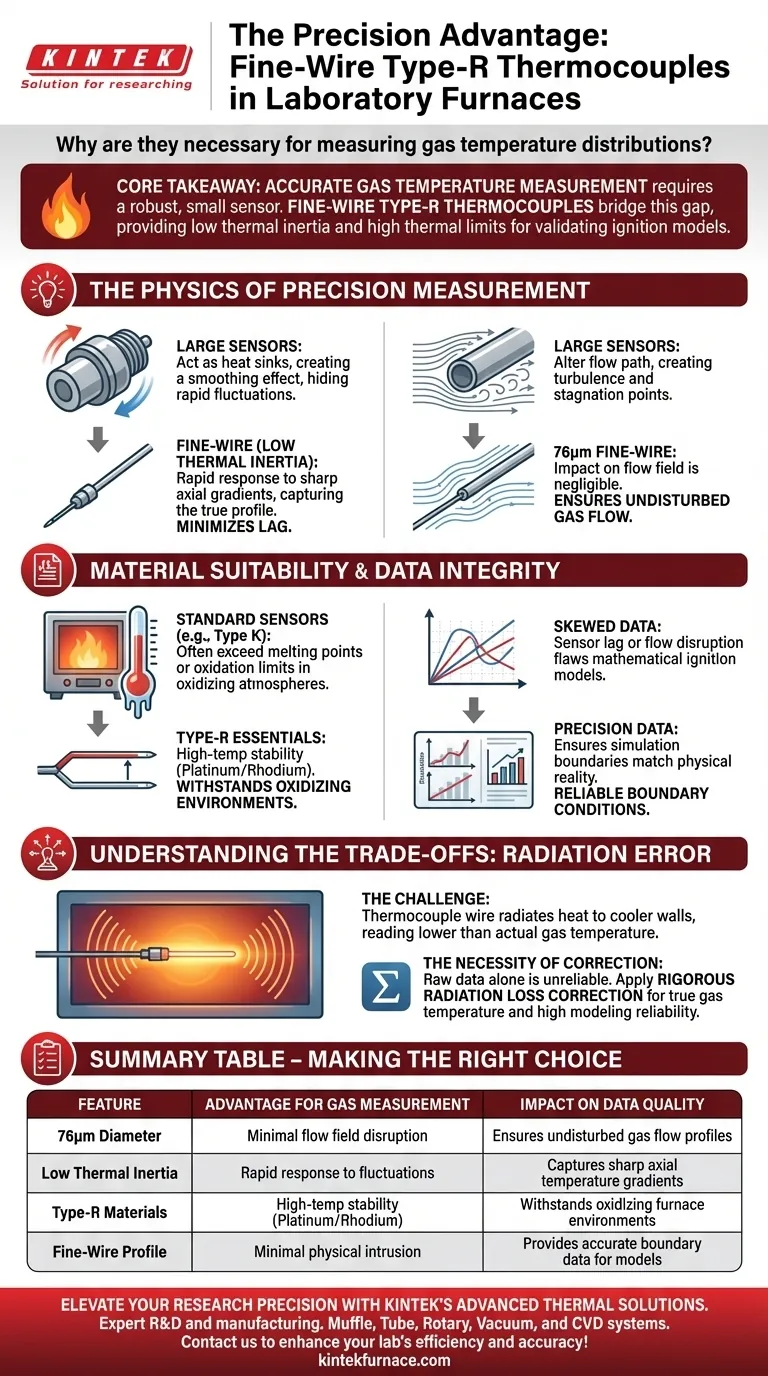

Fine-wire Type-R thermocouples are indispensable for laboratory furnace measurements because they uniquely combine high-temperature endurance with minimal physical intrusion. Their microscopic diameter—often as small as 76 micrometers—allows them to respond instantly to temperature changes without disrupting the gas flow, ensuring data accuracy that standard sensors cannot achieve.

Core Takeaway Accurate gas temperature measurement requires a sensor that is robust enough to survive the heat yet small enough to remain invisible to the flow dynamics. Fine-wire Type-R thermocouples bridge this gap, providing the low thermal inertia and high thermal limits necessary to validate complex mathematical ignition models.

The Physics of Precision Measurement

To understand why standard thermocouples fail in this application, one must look at the physical interaction between the sensor and the environment.

Minimizing Thermal Inertia

Large sensors act as heat sinks; they take time to absorb heat and reach equilibrium with the surrounding gas. This lag creates a "smoothing" effect that hides rapid temperature fluctuations.

Fine-wire thermocouples eliminate this lag. Due to their extremely low mass, they possess very low thermal inertia. This allows them to respond rapidly and accurately to sharp axial temperature gradients, capturing the true profile of the environment rather than a delayed average.

Preserving the Flow Field

Inserting any physical object into a gas stream alters the flow path, potentially creating turbulence or stagnation points that change the local temperature.

The 76-micrometer diameter of these specific thermocouples minimizes this intrusion. The wire is so fine that its impact on the flow field is negligible, ensuring that the measurement reflects the undisturbed state of the gas.

Material Suitability and Data Integrity

Beyond physical dimensions, the metallurgical properties of the sensor and the intended use of the data dictate the choice of Type-R thermocouples.

Withstanding Extreme Heat

Laboratory furnaces often exceed the melting points or oxidation limits of standard base-metal thermocouples (like Type K).

Type-R thermocouples are essential because they possess a high temperature limit. Composed of platinum and rhodium, they remain stable and accurate in oxidizing atmospheres at temperatures where other sensors would fail.

Validating Mathematical Models

The ultimate goal of these measurements is often to provide reliable boundary conditions for mathematical ignition models.

If the input data is skewed by sensor lag or flow disruption, the resulting model will be flawed. The precision provided by fine-wire sensors ensures that the simulation boundaries match physical reality.

Understanding the Trade-offs: Radiation Error

While fine-wire thermocouples are superior for this application, they are not immune to physics.

The Necessity of Correction

In high-temperature gas, the thermocouple wire will radiate heat to the cooler furnace walls. This causes the sensor to read a temperature slightly lower than the actual gas temperature.

You cannot rely on the raw data alone. To achieve the high reliability required for modeling, you must apply a radiation loss correction. This mathematical adjustment compensates for the energy the wire loses via radiation, yielding the true gas temperature.

Making the Right Choice for Your Goal

When designing your experimental setup, consider your specific data requirements.

- If your primary focus is capturing rapid fluctuations: Prioritize the wire diameter (76 micrometers or smaller) to ensure the lowest possible thermal inertia.

- If your primary focus is validating simulation models: Ensure you apply rigorous radiation loss corrections to your raw data to establish accurate boundary conditions.

The correct tool is not just about measuring heat; it is about measuring heat without changing the environment.

Summary Table:

| Feature | Advantage for Gas Measurement | Impact on Data Quality |

|---|---|---|

| 76μm Diameter | Minimal flow field disruption | Ensures undisturbed gas flow profiles |

| Low Thermal Inertia | Rapid response to fluctuations | Captures sharp axial temperature gradients |

| Type-R Materials | High-temp stability (Platinum/Rhodium) | Withstands oxidizing furnace environments |

| Fine-Wire Profile | Minimal physical intrusion | Provides accurate boundary data for models |

Elevate your research precision with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of laboratory high-temperature analysis. Whether you are validating complex ignition models or optimizing material processing, our systems provide the stability and control your data requires. Contact us today to discuss how our high-performance furnaces can enhance your lab's efficiency and accuracy!

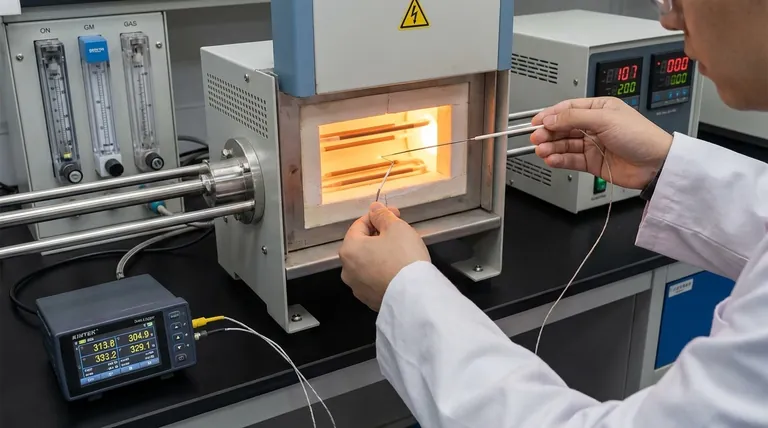

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features of Silicon Carbide Heating Elements? Unlock High-Temp Precision and Durability

- What does low vapor pressure indicate about graphite heating elements? Superior Stability for High-Temperature Applications

- Do ceramic heaters come with timers? Find the Best Timer and Thermostat Options

- Why are silicon carbide heating elements preferred in kilns and pottery? For High-Temp, Uniform Heat & Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- How does an electric heating system ensure stable ignition during coal gasification? Achieving Reliable Process Control

- How does the heating element's electrical resistance affect heat generation? Master Joule Heating for Efficient Thermal Systems

- Why is it important for a ceramic heating element to resist deformation? Ensure Long-Term Reliability & Performance