Electric heating ensures stable ignition through precise thermal regulation and consistent energy delivery. By utilizing high-power heating rods managed by advanced temperature controllers, the system generates a continuous, constant heat source directly within the gasification channels. This setup guarantees that the coal reaches its critical ignition temperature via steady internal-to-external conduction before oxygen is introduced to trigger the reaction.

The core advantage of an electric ignition system is the decoupling of heat generation from combustion. It establishes the necessary thermodynamic conditions first, ensuring that when oxygen is finally introduced, the chemical reaction is immediate, stable, and predictable.

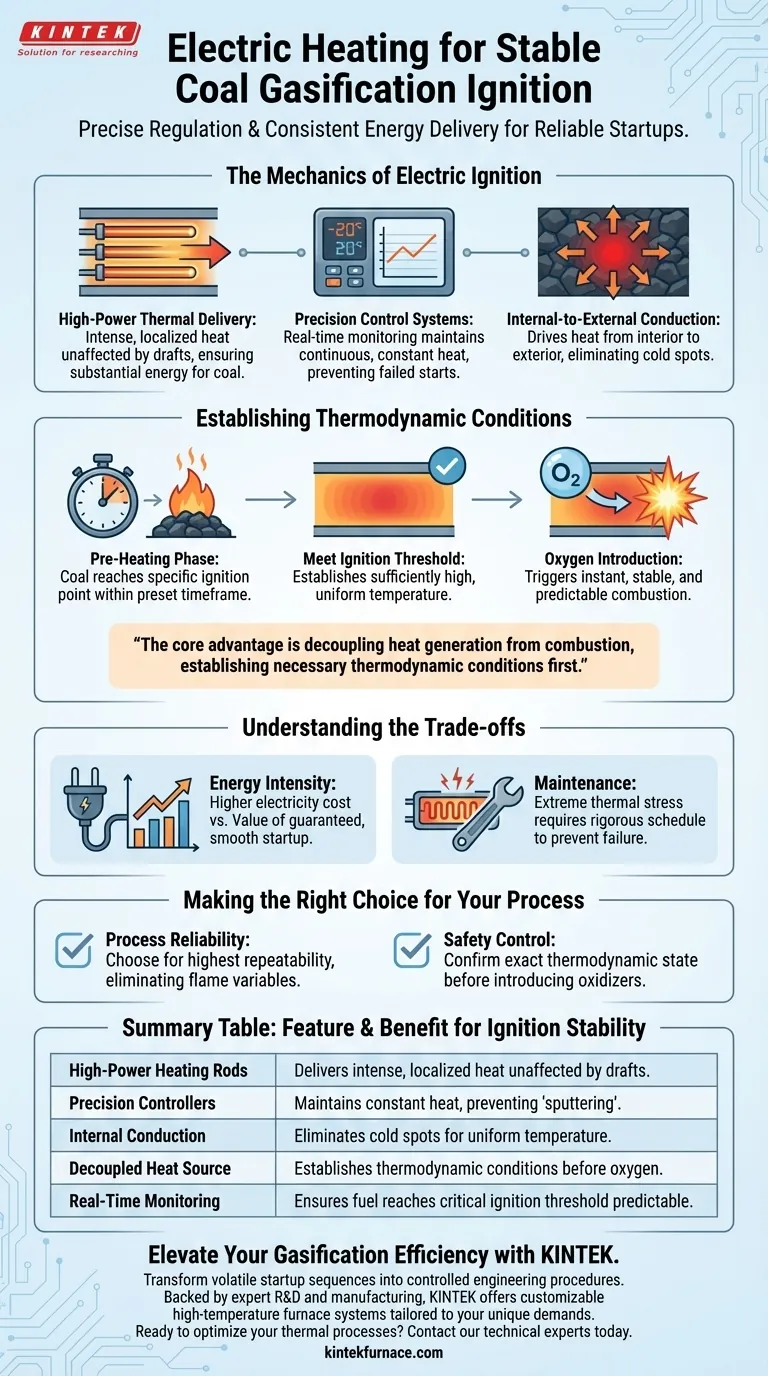

The Mechanics of Electric Ignition

High-Power Thermal Delivery

The foundation of this system lies in the use of high-power heating rods. These components are embedded within the gasification channels to provide the substantial energy required to heat a dense mass of coal. Unlike pilot flames, these rods deliver a localized and intense thermal load that is not susceptible to drafts or pressure fluctuations.

Precision Control Systems

Raw power is ineffective without regulation. The heating rods are paired with precise temperature controllers that monitor the thermal environment in real-time. This ensures the heat source remains continuous and constant, preventing temperature dips that could lead to a failed or "sputtering" ignition.

Internal-to-External Conduction

Stability is achieved through the direction of heat transfer. The system is configured to drive steady heat conduction from the interior of the coal bed toward the exterior. This prevents the formation of cold spots in the core, which are a common cause of unstable gasification during the startup phase.

Establishing Thermodynamic Conditions

Meeting the Ignition Threshold

The primary goal of the pre-heating phase is to bring the coal to its specific ignition point. The electric system allows operators to achieve this within a preset timeframe. This predictability is essential for synchronizing the ignition process with other plant operations.

The Role of Oxygen Introduction

The electric system prepares the environment, but does not trigger the reaction on its own. It creates the necessary thermodynamic conditions—specifically, a sufficiently high and uniform temperature. Once this thermal baseline is established, oxygen is introduced, causing the pre-heated coal to react instantly and maintain stable combustion.

Understanding the Trade-offs

Energy Intensity

While highly stable, electric heating can be energy-intensive compared to auxiliary fuel burners. Operators must weigh the cost of electricity against the value of a guaranteed, smooth startup.

Maintenance of Heating Elements

Heating rods are subjected to extreme thermal stress and potential chemical corrosion inside the gasifier. This requires a rigorous maintenance schedule to ensure the rods do not fail midway through the ignition sequence.

Making the Right Choice for Your Process

To determine if an electric heating system fits your gasification requirements, consider your operational priorities:

- If your primary focus is process reliability: The electric system offers the highest level of repeatability, eliminating the variables associated with flame-based ignition.

- If your primary focus is safety control: Precise temperature controllers allow you to confirm the fuel is at the exact thermodynamic state required before introducing oxidizers.

By standardizing the thermal environment prior to combustion, electric ignition transforms a volatile startup process into a controlled engineering procedure.

Summary Table:

| Feature | Benefit for Ignition Stability |

|---|---|

| High-Power Heating Rods | Delivers intense, localized heat unaffected by drafts or pressure. |

| Precision Controllers | Maintains a constant heat source to prevent "sputtering" or failed starts. |

| Internal Conduction | Eliminates cold spots in the coal bed for uniform temperature distribution. |

| Decoupled Heat Source | Establishes thermodynamic conditions before oxygen is introduced for instant reaction. |

| Real-Time Monitoring | Ensures the fuel reaches the critical ignition threshold predictably. |

Elevate Your Gasification Efficiency with KINTEK

Unstable ignition leads to costly downtime and safety risks. At KINTEK, we provide the specialized thermal expertise required to transform volatile startup sequences into controlled, repeatable engineering procedures.

Backed by expert R&D and manufacturing, KINTEK offers customizable high-temperature furnace systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—tailored to meet the unique thermodynamic demands of your laboratory or industrial application. Our precision heating solutions ensure your materials reach exact temperature thresholds with unmatched consistency.

Ready to optimize your thermal processes? Contact our technical experts today to discuss your custom heating requirements!

Visual Guide

References

- Lele Feng, Jiaxuan Sun. H2 production in underground coal gasification with pretreatment by non-focusing microwave. DOI: 10.3389/fchem.2025.1586267

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is a heating element and its key components? Discover How It Powers Efficient Heat Generation

- Why are silicon carbide heating elements suitable for high-temperature applications? Discover Their Key Benefits

- What material is used to make heating elements? From Nichrome to Kanthal & Beyond

- Why is the combined use of a thermocouple and a temperature recorder necessary in EPT? Ensure Precise Thermal Control

- What are the key benefits of silicon carbide heating elements? Achieve High-Temp Efficiency and Durability

- Why is chemical inertness an advantage for graphite heating elements? Ensure Purity and Longevity in High-Temp Processes

- How do MoSi2 heating elements resist deformation and oxidation at high temperatures? Discover Their Self-Healing Secrets

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat