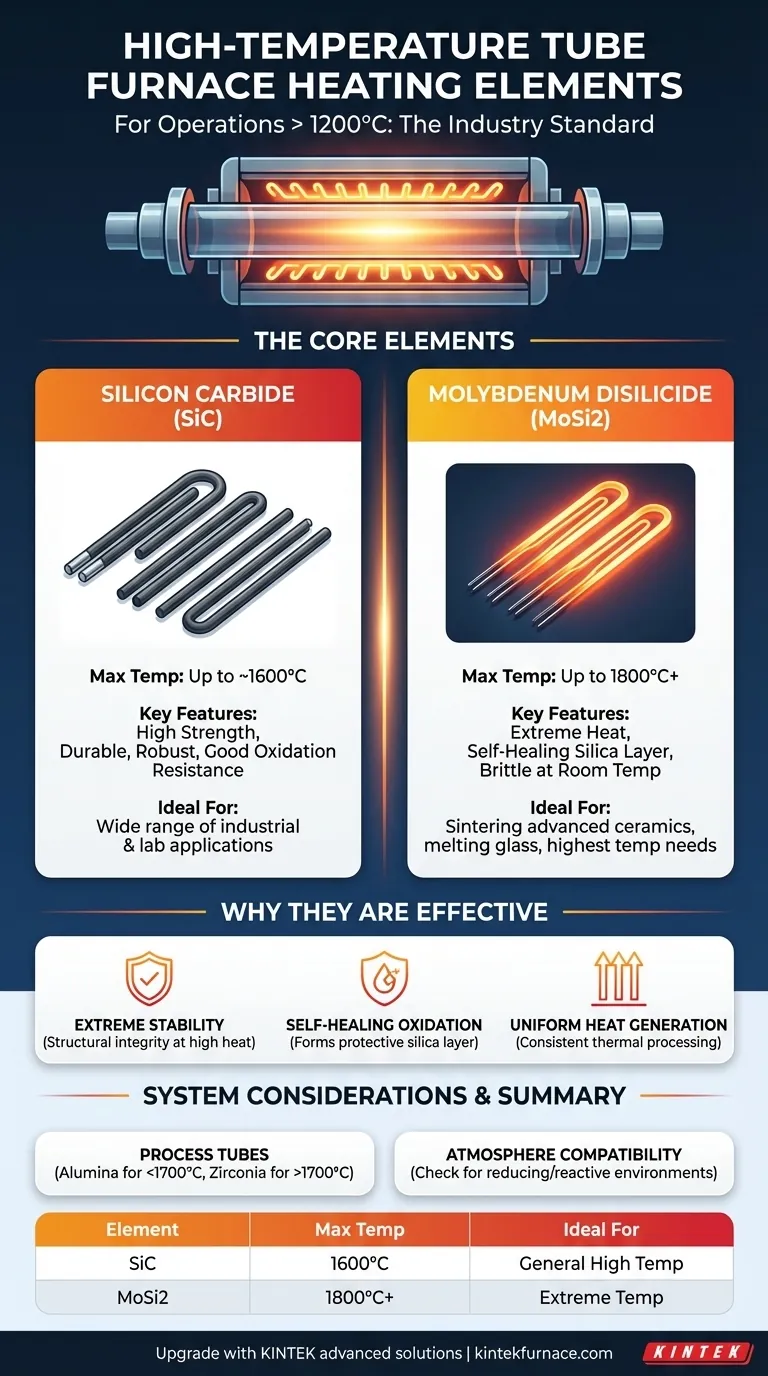

For high-temperature tube furnaces operating above 1200°C, the industry relies almost exclusively on two types of heating elements: Silicon Carbide (SiC) and Molybdenum Disilicide (MoSi2). These materials are chosen for their unique ability to generate extreme heat while resisting the rapid degradation and oxidation that would destroy conventional metal wire elements.

Choosing the right furnace is not just about its maximum temperature rating. The critical decision lies in matching the heating element's specific properties—its temperature limits, durability, and chemical compatibility—to the precise demands of your heat treatment process.

The Core High-Temperature Heating Elements

Tube furnaces perform heat treatment by transferring thermal energy from heating elements to a process tube. For temperatures exceeding 1200°C, only specialized ceramic-based materials can provide the necessary performance and lifespan.

Silicon Carbide (SiC) Elements

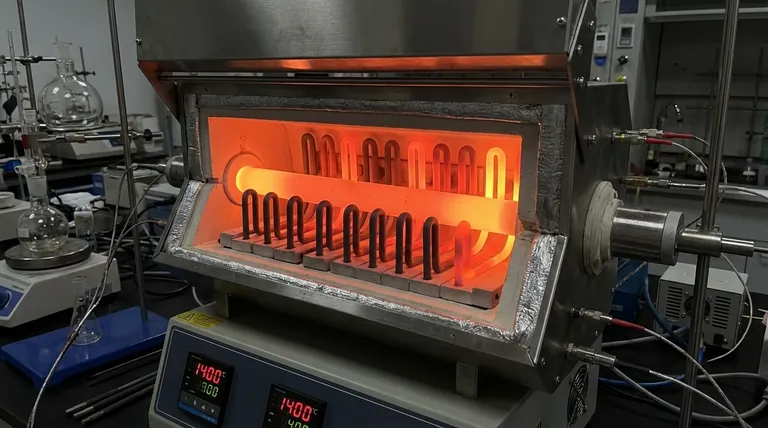

Silicon Carbide elements are a robust and widely used solution for high-temperature applications. They are typically formed into rods or U-shapes.

These elements are known for their high strength and durability, offering reliable service in many industrial and laboratory settings. They are excellent for processes operating up to approximately 1600°C.

Molybdenum Disilicide (MoSi2) Elements

Often referred to as "silicon molybdenum rods," MoSi2 elements represent the peak of heating element technology for air-atmosphere furnaces.

These elements can reach exceptionally high temperatures, often up to 1800°C or even higher. They are the standard choice for applications requiring extreme heat, such as sintering advanced ceramics or melting certain glasses.

Other Elements for Context

While SiC and MoSi2 dominate high-temperature applications, other materials are used in different contexts.

Resistance wires (like Kanthal) are common but are limited to lower temperatures, typically below 1200°C. Graphite elements can achieve very high temperatures but require a vacuum or inert gas atmosphere to prevent immediate burnout.

Why These Materials Are So Effective

The choice of SiC and MoSi2 is not arbitrary; it is based on fundamental material science that makes them uniquely suited for extreme heat in an oxidizing environment.

Extreme Temperature Stability

Both SiC and MoSi2 maintain their structural integrity at temperatures that would melt or soften most other materials. This stability is essential for consistent and repeatable thermal processing.

Self-Healing Oxidation Resistance

At high temperatures, both materials react with oxygen in the air to form a thin, protective outer layer of silica glass (SiO2). This passive layer prevents the underlying material from further oxidation, dramatically extending the element's operational life.

Uniform Heat Generation

In a furnace, these elements are suspended in arrays along the sides of the process tube. This configuration allows for highly uniform heat distribution, which is critical for ensuring that the entire sample within the tube experiences the same thermal conditions.

Understanding the Trade-offs and System Considerations

Selecting a heating element is only one part of designing a successful high-temperature process. The entire furnace system must work in harmony.

The Impact of Process Tube Material

The heating element's capability is useless if the process tube cannot withstand the heat.

Alumina (Al2O3) tubes are common for high-temperature work but can be susceptible to thermal shock if heated or cooled too quickly. Zirconia (ZrO2) tubes are required for the highest temperature ranges (above 1700°C) that MoSi2 elements can achieve.

Atmosphere Compatibility

Many high-temperature processes require a specific atmosphere (e.g., argon, nitrogen, or vacuum) to prevent unwanted chemical reactions with the sample.

You must ensure that the chosen heating element is compatible with your process atmosphere. While SiC and MoSi2 are excellent in air, their performance can change in highly reducing or reactive environments.

Element Lifespan and Brittleness

MoSi2 elements, while capable of the highest temperatures, can be brittle at room temperature and require careful handling. SiC elements are generally more mechanically robust but have a lower maximum operating temperature.

Making the Right Choice for Your Goal

Your decision should be guided by the specific temperature and environmental needs of your application.

- If your primary focus is operating up to 1600°C: Silicon Carbide (SiC) elements offer a highly reliable and durable solution for a wide range of applications.

- If your primary focus is achieving the highest possible temperatures (1600°C to 1800°C+): Molybdenum Disilicide (MoSi2) elements are the definitive choice for their superior heat generation and stability in air.

- If your primary focus is process control: Remember that the heating element is part of a system that includes the process tube and atmosphere, all of which must be compatible.

Understanding these core components empowers you to select a furnace that precisely matches your material processing goals.

Summary Table:

| Element Type | Max Temperature | Key Features | Ideal For |

|---|---|---|---|

| Silicon Carbide (SiC) | Up to 1600°C | High strength, durable, good oxidation resistance | Applications up to 1600°C, robust industrial use |

| Molybdenum Disilicide (MoSi2) | Up to 1800°C+ | Extreme heat, self-healing oxidation layer, brittle at room temp | Highest temperature needs, sintering, glass melting |

| Other Elements (e.g., Kanthal, Graphite) | Below 1200°C or specific atmospheres | Limited to lower temps or require inert/vacuum conditions | Lower temperature or specialized atmosphere processes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements and full systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how we can support your high-temperature processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism