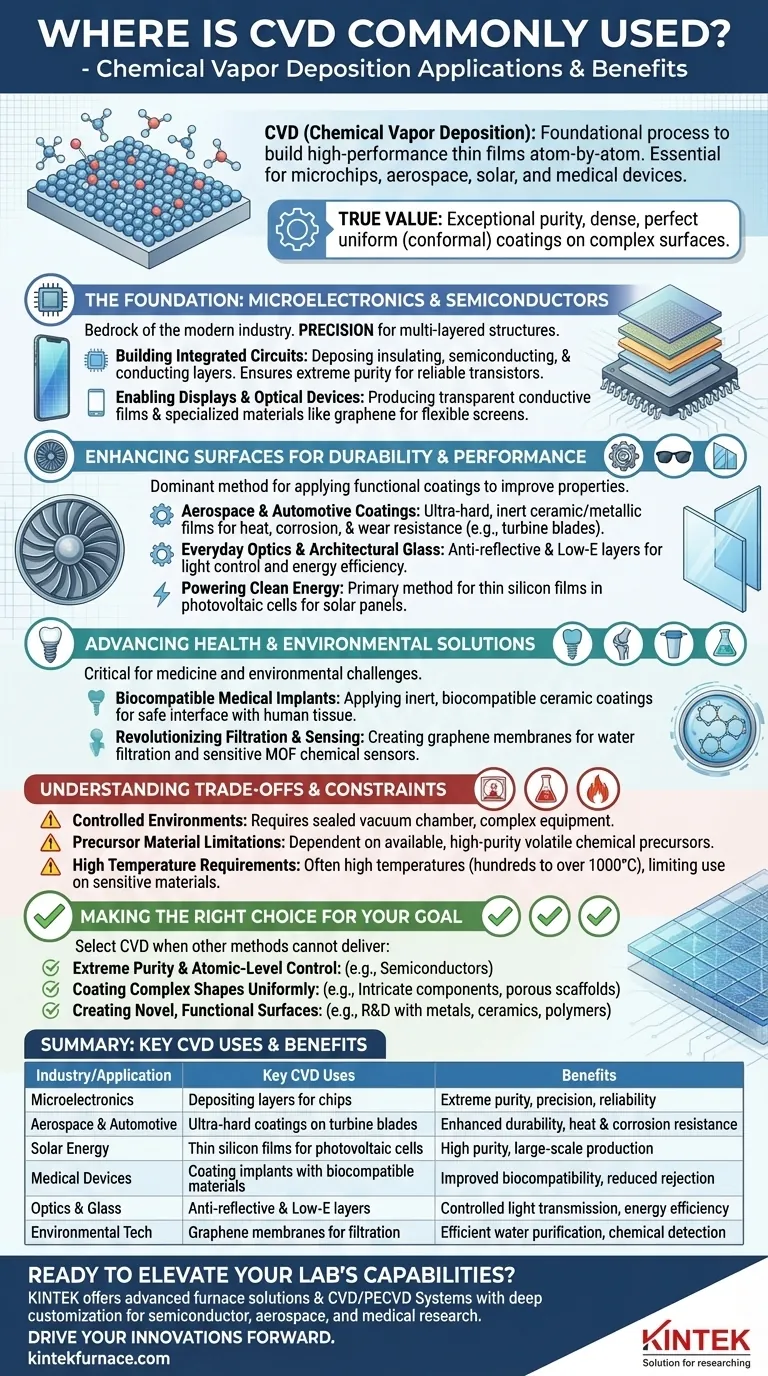

At its core, Chemical Vapor Deposition (CVD) is a foundational manufacturing process used to build high-performance thin films atom-by-atom. It is most famously used to fabricate the microchips in all modern electronics, but its applications extend far beyond, into aerospace, solar energy, and advanced medical devices. This versatility makes it an indispensable tool across nearly every high-technology sector.

The true value of CVD lies not just in the wide range of industries it serves, but in its unique ability to create exceptionally pure, dense, and perfectly uniform (conformal) coatings on complex surfaces—a feat that is often impossible with other methods.

The Foundation: Microelectronics and Semiconductors

CVD is the bedrock of the modern semiconductor industry. Its precision is essential for building the microscopic, multi-layered structures that power computers, phones, and servers.

Building Integrated Circuits Layer by Layer

The fabrication of an integrated circuit (or "chip") involves depositing dozens of successive thin films. CVD is used to precisely deposit the essential materials—insulating layers (like silicon dioxide), semiconducting layers (like silicon), and conducting layers (like tungsten).

This process ensures the extreme purity and structural perfection required for billions of transistors to function reliably on a single chip.

Enabling Displays and Optical Devices

CVD is also used to produce the transparent conductive films and specialized materials needed for modern displays. This includes creating thin sheets of advanced materials like graphene, which hold promise for next-generation flexible TV screens and other optical devices.

Enhancing Surfaces for Durability and Performance

Beyond electronics, CVD is a dominant method for applying functional coatings that dramatically improve the properties of an underlying material.

Aerospace and Automotive Coatings

In high-stress environments, components must resist extreme heat, corrosion, and wear. CVD is used to apply ultra-hard, chemically inert coatings to parts like turbine blades, engine components, and cutting tools.

These ceramic or metallic films create a durable barrier that significantly extends the component's operational lifespan.

Everyday Optics and Architectural Glass

The anti-reflective coating on your sunglasses or the low-emissivity (Low-E) layer on energy-efficient windows is often applied using CVD. The process allows for the deposition of multiple, incredibly thin optical layers that control how light is reflected or transmitted.

Powering Clean Energy

The manufacturing of photovoltaic cells for solar panels relies heavily on CVD. It is the primary method for depositing the thin silicon films that convert sunlight into electricity, requiring a combination of high purity and large-scale industrial throughput.

Advancing Health and Environmental Solutions

The precision and material flexibility of CVD make it a critical tool for solving challenges in medicine and environmental science.

Biocompatible Medical Implants

When a medical device like a dental implant or an artificial joint is placed in the body, it must not be rejected. CVD is used to apply a biocompatible coating, often a ceramic, that acts as an inert and safe interface between the implant and human tissue.

It is also being explored for creating advanced drug-delivery systems that can release therapies with greater efficiency.

Revolutionizing Filtration and Sensing

The ability to create novel materials with unique properties has made CVD essential for environmental technology. This includes producing graphene membranes for highly efficient water filtration or depositing metal-organic frameworks (MOFs) onto surfaces to create sensitive chemical sensors.

Understanding the Trade-offs and Process Constraints

While powerful, CVD is not a universal solution. Its application involves specific requirements and limitations that are important to understand.

The Need for Controlled Environments

CVD is a delicate and sensitive process. It must be performed within a sealed vacuum chamber or reactor to prevent atmospheric contamination and ensure the purity of the film. This requirement makes the equipment complex and expensive.

Precursor Material Limitations

The "vapor" in Chemical Vapor Deposition comes from volatile chemical precursors that contain the elements you wish to deposit. The process is entirely dependent on the availability of suitable, high-purity precursor gases, which may not exist or may be prohibitively expensive for certain materials.

High Temperature Requirements

Traditional CVD processes often operate at very high temperatures (hundreds or even over a thousand degrees Celsius). This can prevent its use on temperature-sensitive materials, such as many plastics or pre-fabricated components that cannot withstand the heat.

Making the Right Choice for Your Goal

Selecting CVD is a decision based on the specific outcome you need to achieve. Its strengths are most apparent when the goal demands properties that other methods cannot deliver.

- If your primary focus is extreme purity and atomic-level control: CVD is the industry standard for applications like semiconductors, where even minuscule impurities can cause device failure.

- If your primary focus is coating a complex shape uniformly: CVD's ability to create a conformal film is its key advantage for parts like intricate engine components or porous medical scaffolds.

- If your primary focus is creating a novel, functional surface: CVD's versatility in depositing a vast range of materials—from metals to ceramics to polymers—makes it an ideal tool for research and development.

Ultimately, Chemical Vapor Deposition is a fundamental tool for engineering materials and surfaces from the bottom up.

Summary Table:

| Industry/Application | Key CVD Uses | Benefits |

|---|---|---|

| Microelectronics | Depositing insulating, semiconducting, and conducting layers for chips | Extreme purity, precision, and reliability |

| Aerospace & Automotive | Applying ultra-hard coatings on turbine blades and engine parts | Enhanced durability, heat resistance, and corrosion protection |

| Solar Energy | Fabricating thin silicon films for photovoltaic cells | High purity and large-scale production capability |

| Medical Devices | Coating implants with biocompatible materials for safety | Improved biocompatibility and reduced rejection |

| Optics & Glass | Creating anti-reflective and low-emissivity layers | Controlled light transmission and energy efficiency |

| Environmental Tech | Producing graphene membranes for filtration and sensors | Efficient water purification and sensitive chemical detection |

Ready to elevate your lab's capabilities with advanced high-temperature furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge equipment, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve superior results in areas like semiconductor fabrication, aerospace coatings, and medical device development. Contact us today to discuss how our tailored solutions can drive your innovations forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings