The primary technical advantage of using a laboratory rotary kiln furnace for zirconium-based catalysts is the dynamic movement of the feedstock during processing. By utilizing a rotating furnace tube, the equipment ensures that the precursor powder maintains continuous, uniform contact with reaction atmospheres, such as ammonia and nitrogen gas mixtures. This mechanical motion prevents the uneven heating and powder accumulation typical of static furnaces, directly resulting in superior product consistency.

The motion of a rotary kiln solves the critical challenge of static zones in heat treatment. By ensuring every particle receives identical exposure to heat and gas, it guarantees catalyst products with highly uniform phase composition and precise carbon content.

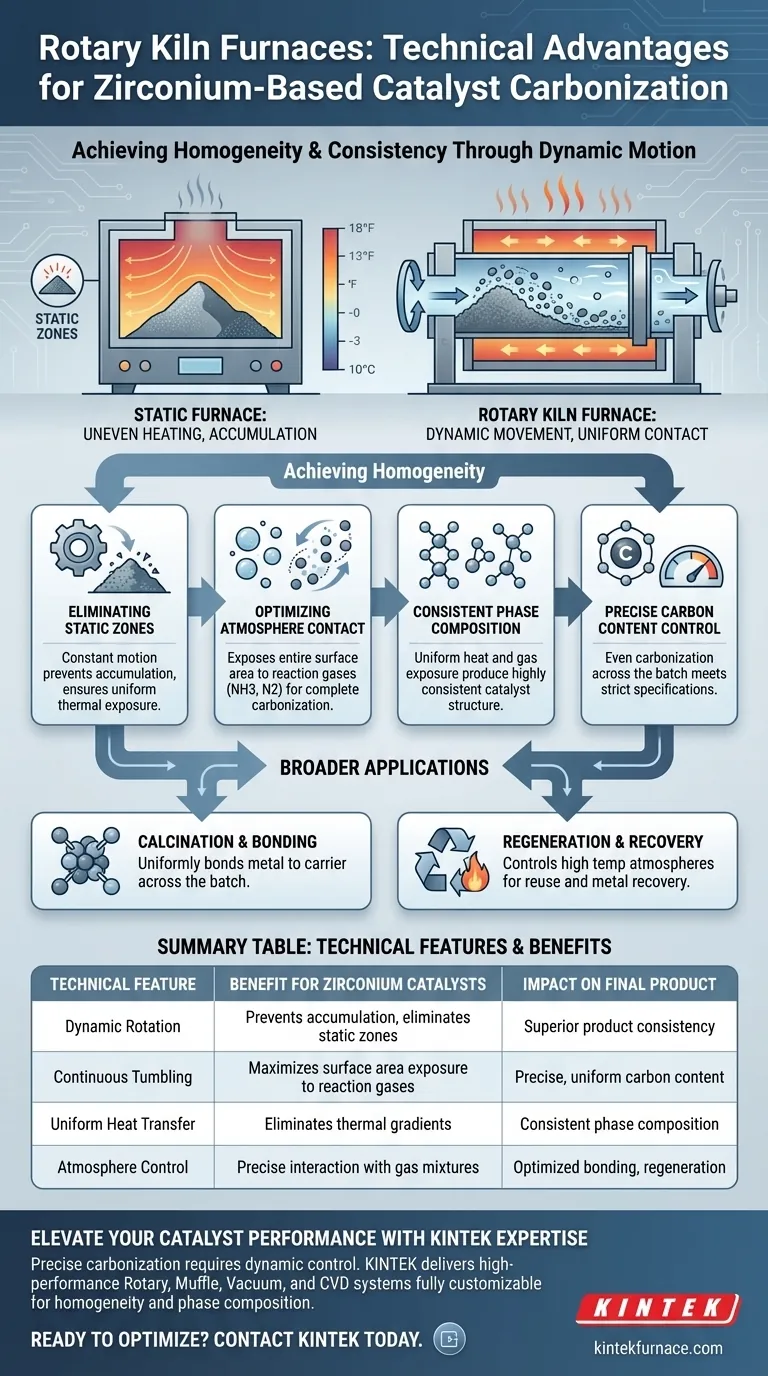

Achieving Homogeneity in Carbonization

Eliminating Static Zones

In traditional static furnaces, precursor powders often accumulate in piles. This creates thermal gradients where the outer layer heats faster than the core.

A rotary kiln eliminates this issue by keeping the furnace tube in constant motion. This prevents powder accumulation and ensures that every grain of the zirconium precursor is subjected to the same thermal conditions.

Optimizing Atmosphere Contact

The carbonization process relies heavily on the interaction between the solid powder and the gas phase.

The rotation of the kiln continually tumbles the powder, exposing the entire surface area of the particles to the reaction atmosphere. This ensures a complete reaction with gases like ammonia and nitrogen, rather than a superficial surface treatment.

Consistent Phase Composition

Uneven heating often results in a final product with varied chemical structures, which can degrade catalytic performance.

Because the rotary kiln provides uniform heat and gas exposure, it produces a catalyst with a highly consistent phase composition. This homogeneity is essential for reliable performance in downstream chemical applications.

Precise Carbon Content Control

The uniformity of the process allows for tighter control over the final carbon content of the catalyst.

By preventing hot spots and dead zones, the kiln ensures that carbonization occurs evenly throughout the batch. This results in a product that meets strict specifications for carbon integration.

Broader Applications in Catalyst Processing

Calcination and Bonding

Beyond carbonization, rotary kilns are the preferred equipment for the calcination process.

This thermal treatment is critical for mechanically and chemically bonding the catalyst metal to its chosen carrier. The rotary motion ensures this bond forms uniformly across the entire batch.

Regeneration and Recovery

The utility of a rotary kiln extends to the management of spent catalysts.

Due to their ability to maintain controlled atmospheres at high temperatures, these furnaces are effective for regenerating catalysts for reuse. They also facilitate the recovery of valuable metals from spent materials, enhancing the sustainability of the production cycle.

Making the Right Choice for Your Goal

Selecting the correct furnace depends on the specific requirements of your catalyst production line.

- If your primary focus is maximizing product consistency: Prioritize the rotary kiln to ensure uniform phase composition and precise carbon content through constant powder motion.

- If your primary focus is lifecycle management: Leverage the kiln's high-temperature and atmosphere control capabilities to regenerate spent catalysts or recover metals.

The rotary kiln transforms the variable nature of batch processing into a controlled, uniform operation, ensuring your zirconium-based catalysts perform reliably.

Summary Table:

| Technical Feature | Benefit for Zirconium Catalysts | Impact on Final Product |

|---|---|---|

| Dynamic Rotation | Prevents powder accumulation and eliminates static zones | Ensures superior product consistency |

| Continuous Tumbling | Maximizes surface area exposure to reaction gases | Achieves precise and uniform carbon content |

| Uniform Heat Transfer | Eliminates thermal gradients across the batch | Guarantees consistent phase composition |

| Atmosphere Control | Precise interaction with NH3 and N2 gas mixtures | Optimized chemical bonding and regeneration |

Elevate Your Catalyst Performance with KINTEK Expertise

Precise carbonization requires more than just heat; it requires the dynamic control only a specialized rotary system can provide. KINTEK delivers high-performance Rotary, Muffle, Vacuum, and CVD systems designed to meet the rigorous demands of laboratory research and industrial scaling.

Backed by expert R&D and precision manufacturing, our high-temperature furnaces are fully customizable to ensure your zirconium-based catalysts achieve perfect homogeneity and phase composition.

Ready to optimize your carbonization process? Contact KINTEK today to discuss your custom furnace requirements with our engineering team.

Visual Guide

References

- A. Ueno, Takashi Nakagawa. Synthesis and characterization of zirconium oxide-based catalysts for the oxygen reduction reaction via the heat treatment of zirconium polyacrylate in an ammonia atmosphere. DOI: 10.1007/s10853-025-10620-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is an industrial-grade rotary reactor necessary in the oil sludge pyrolysis process? Maximize Yield & Efficiency

- What is a rotary furnace and what is it used for? Achieve Uniform Heating for Industrial Materials

- What are the main industrial applications of rotary furnaces? Boost Efficiency in Metallurgy, Chemicals & Waste Management

- How do rotary tube furnaces contribute to catalyst synthesis? Enhance Uniformity and Performance

- How are rotary tube furnaces classified? Choose the Right Type for Your Lab or Production

- What are the key operational features of the Rotary Tube Tilt Furnace? Master Precise Material Processing

- What are the main components of a rotary tube furnace? Unlock Efficient Thermal Processing for Your Lab

- What role do indirect-fired rotary kilns play in carbonization and activation processes? Unlock Precise Control for High-Purity Carbon Products