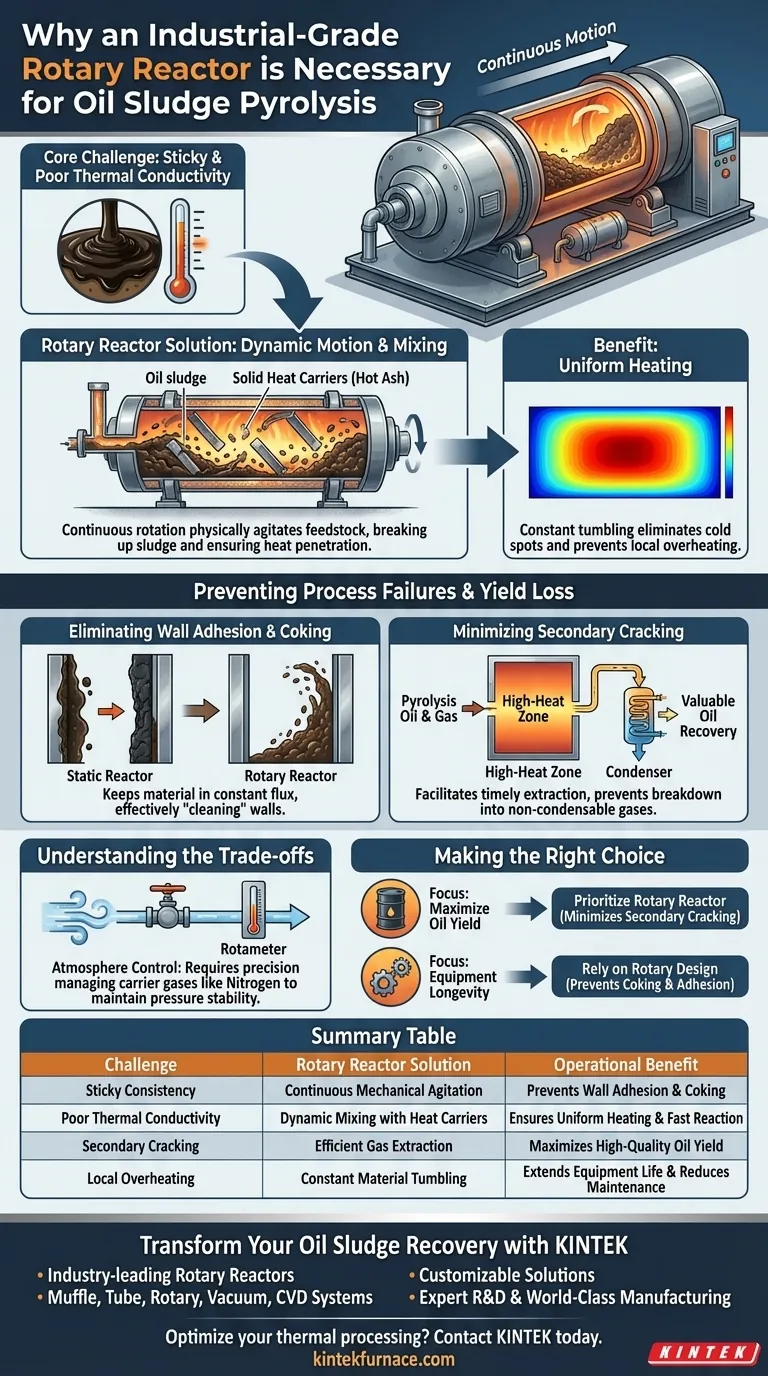

An industrial-grade rotary reactor is necessary in oil sludge pyrolysis primarily to overcome the material's poor thermal conductivity and sticky consistency through continuous mechanical motion. By utilizing a rotating furnace body, the system ensures that oil sludge is thoroughly mixed with solid heat carriers (such as hot ash), creating a dynamic environment that is critical for efficient processing.

The core challenge of oil sludge pyrolysis is preventing the material from adhering to reactor walls and overheating locally. The rotary reactor solves this by maintaining constant motion, ensuring uniform heat transfer and preventing the formation of coke, which maximizes the yield of high-quality oil.

Overcoming Thermal and Physical Challenges

The Role of Dynamic Mixing

Oil sludge is a viscous, complex mixture that resists even heating in static environments. The rotary reactor utilizes continuous rotation to physically agitate the feedstock.

This motion forces the sludge to mix thoroughly with solid heat carriers, such as hot ash. This contact is essential for breaking up the sludge and ensuring that heat penetrates the material efficiently.

Achieving Uniform Heating

In a static reactor, heat transfer is often uneven, leading to cold spots where reaction fails and hot spots where material burns.

The dynamic operation of the rotary reactor creates superior heat transfer conditions. By constantly tumbling the material, the reactor ensures every portion of the sludge receives consistent thermal energy, facilitating a stable pyrolysis process.

Preventing Process Failures and Yield Loss

Eliminating Wall Adhesion and Coking

One of the biggest risks in pyrolysis is the sludge sticking to the internal walls of the reactor.

If sludge adheres to the hot walls, it undergoes coking—burning into a solid, carbon-heavy residue rather than vaporizing into oil. The rotary design prevents this adhesion by keeping the material in constant flux, effectively "cleaning" the walls through friction and motion.

Minimizing Secondary Cracking

To recover valuable oil, the gas produced during pyrolysis must be extracted quickly.

The rotary reactor facilitates the timely extraction of pyrolysis oil and gas from the reaction zone. If these gases linger too long in the high-heat zone, they undergo "secondary cracking," breaking down further into less valuable non-condensable gases.

Understanding the Trade-offs

Complexity of Atmosphere Control

While the mechanical rotation handles the solids, managing the gaseous atmosphere requires precision.

Although the reactor design itself aids in gas extraction, additional controls (such as rotameters) are often required to regulate the flow of inert carrier gases like Nitrogen. This ensures that the generated volatiles are swept out at the correct rate to maintain internal pressure stability, adding a layer of operational complexity to the mechanical benefits.

Making the Right Choice for Your Goal

When designing or selecting a pyrolysis system for oil sludge, consider your specific operational targets:

- If your primary focus is maximizing oil yield: Prioritize a rotary reactor to minimize secondary cracking and ensure volatiles are extracted before they degrade.

- If your primary focus is equipment longevity: Rely on the rotary design to prevent coking and wall adhesion, which significantly reduces maintenance downtime and physical wear.

The rotary reactor converts a chaotic, sticky feedstock into a controlled, high-efficiency thermal process.

Summary Table:

| Challenge in Sludge Pyrolysis | Rotary Reactor Solution | Operational Benefit |

|---|---|---|

| Sticky Consistency | Continuous mechanical agitation | Prevents wall adhesion and coking |

| Poor Thermal Conductivity | Dynamic mixing with heat carriers | Ensures uniform heating and fast reaction |

| Secondary Cracking | Efficient gas extraction | Maximizes high-quality oil yield |

| Local Overheating | Constant material tumbling | Extends equipment life and reduces maintenance |

Transform Your Oil Sludge Recovery with KINTEK

Don’t let poor heat transfer and coking compromise your pyrolysis yields. KINTEK provides industry-leading industrial-grade rotary reactors designed to handle the toughest, most viscous feedstocks with precision.

Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial requirements. Our advanced rotary designs ensure uniform heat distribution and prevent material adhesion, allowing you to maximize oil recovery and operational uptime.

Ready to optimize your thermal processing? Contact KINTEK today to consult with our specialists and find the perfect high-temperature solution for your needs.

Visual Guide

References

- Zhengyang Zhang, Changtao Yue. Theoretical Calculation of Heat and Material Balance for Oil Sludge Pyrolysis Process by Solid Heat Carrier Method. DOI: 10.3390/en18020329

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What factors are critical in determining the temperature profile for a rotary kiln? Optimize Heat Control for Peak Performance

- How does advanced sealing technology improve rotary kiln performance? Boost Efficiency & Quality Now

- How is the appropriate temperature profile for a rotary kiln determined? Unlock Precision with TGA Analysis

- What key principles make rotary kilns efficient for high-temperature processing? Unlock Optimal Thermal Processing

- What types of cement can be produced using a rotary cement kiln? Unlock Versatile Clinker for Diverse Cement Types

- What safety and environmental controls are integrated into rotary furnaces? Ensure Safe, Eco-Friendly Operations

- What is a rotary kiln and what is its primary purpose? Discover Its Industrial Heat Processing Power

- What safety measures are typically included in a rotary tube sintering furnace? Ensure Reliable High-Temperature Processing