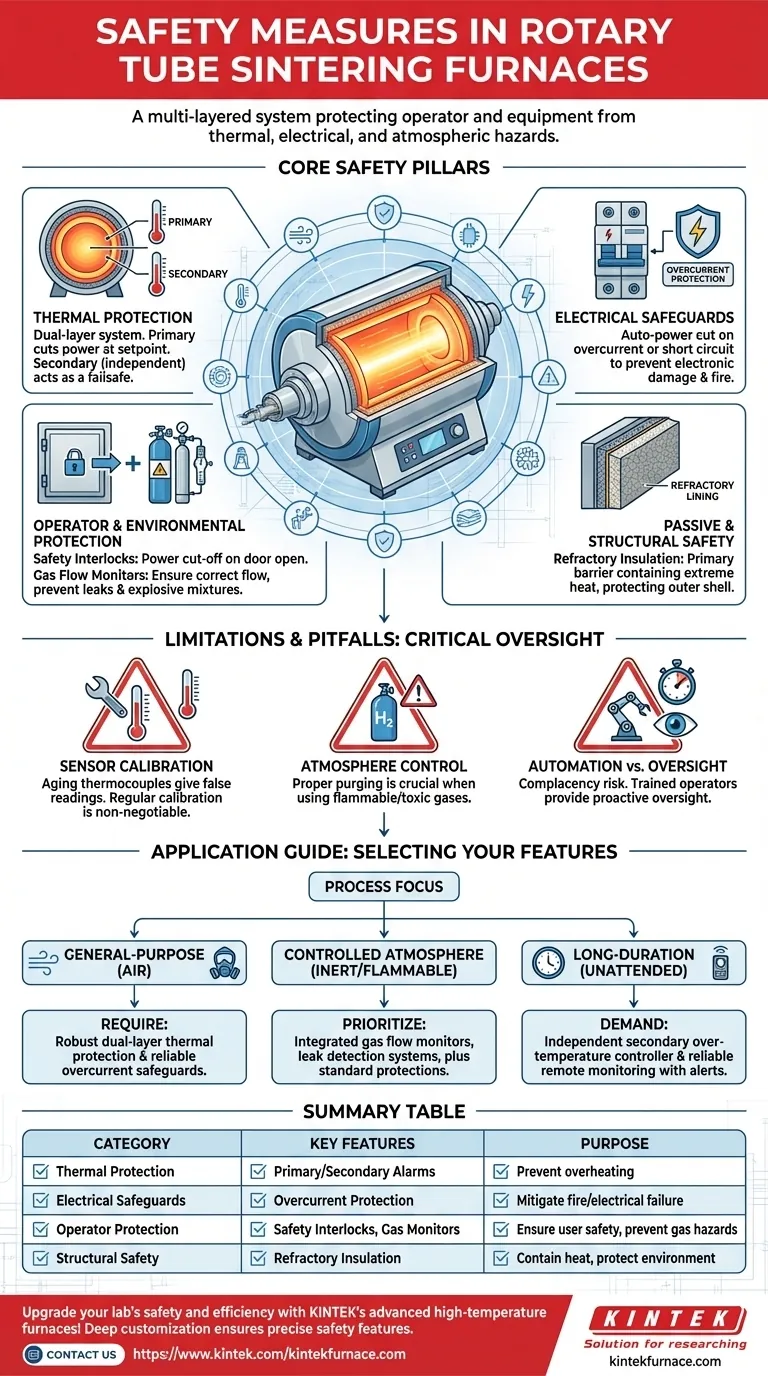

In short, rotary tube sintering furnaces are equipped with a multi-layered safety system designed to protect both the operator and the equipment. Key safety measures include redundant over-temperature protection, electrical safeguards like overcurrent protection, physical safety interlocks, and specialized monitors for controlling gas atmospheres. These systems work together to mitigate the inherent risks of high-temperature processing.

A modern rotary tube furnace does not rely on a single safety feature. Instead, it integrates a series of active electronic monitors and passive physical barriers to manage thermal, electrical, and atmospheric hazards, ensuring a safe and reliable operating environment.

The Core Pillars of Furnace Safety

To understand the safety of these systems, it's helpful to break the features down by the type of hazard they are designed to prevent. The primary risks involve extreme heat, high electrical loads, and the use of controlled gas atmospheres.

Thermal Protection Systems

The most immediate danger in any furnace is excessive heat. Rotary tube furnaces employ a dual-layer approach to prevent overheating.

First, a primary over-temperature alarm is standard. The system's thermocouple sends temperature data to the main controller, which will cut power to the heating elements if the temperature exceeds a user-defined setpoint.

Second, a secondary (or independent) over-temperature protection system is often included. This uses a separate thermocouple and controller to act as a hard-wired failsafe, cutting power if the primary system fails for any reason.

Electrical Safeguards

High-power heating elements draw significant current, creating potential electrical hazards.

Overcurrent protection is a critical feature, functioning like a sophisticated circuit breaker. If the system draws too much power due to a short circuit or component failure, it automatically cuts power to prevent damage to the electronics and reduce fire risk.

Operator and Environmental Protection

These features are designed to protect the user and the surrounding lab environment from direct harm.

A safety interlock is a physical switch that prevents unsafe operation. The most common example is an automatic power cut-off that activates when the furnace door or cover is opened, preventing exposure to extreme heat and protecting the heating elements from thermal shock.

Gas flow monitors are essential when working with controlled atmospheres. These systems ensure that inert or reactive gases are flowing at the correct rate, preventing the formation of potentially explosive mixtures (e.g., with air) or hazardous conditions like gas leaks.

Passive and Structural Safety

Beyond active electronic systems, the furnace's very construction is a safety feature.

The furnace chamber is lined with high-quality refractory material. This insulation not only ensures thermal efficiency but also serves as the primary barrier for containing the extreme heat, protecting the outer metal shell and the surrounding area.

Understanding the Limitations and Pitfalls

While modern furnaces are equipped with robust safety features, they are not infallible. User awareness and proper maintenance are critical components of a safe operation.

The Myth of the 'Failsafe' System

Safety systems rely on accurate sensors. An aging or improperly installed thermocouple can provide false readings, rendering the over-temperature protection ineffective. Regular calibration and inspection of all sensors are non-negotiable for ensuring safety.

The Complexity of Atmosphere Control

Using flammable gases like hydrogen or toxic gases like ammonia introduces significant risk. A gas flow monitor is only one part of the solution; operators must be thoroughly trained on proper purging procedures to ensure no dangerous residual air is present before heating.

Automation Does Not Replace Oversight

Advanced automation and remote monitoring allow for long, unattended runs, but this convenience can lead to complacency. Alarms and automated shutdowns are reactive measures; a trained operator provides proactive oversight that can prevent problems before they trigger a safety system.

How to Apply This to Your Process

When evaluating a rotary tube furnace, your specific application will determine which safety features are most critical.

- If your primary focus is general-purpose sintering in air: Ensure the furnace has robust dual-layer over-temperature protection and reliable overcurrent safeguards as a baseline.

- If your primary focus is processing with inert or flammable gases: Prioritize a system with integrated gas flow monitors and leak detection systems in addition to all standard thermal and electrical protections.

- If your primary focus is long-duration, unattended operation: Demand a system with an independent secondary over-temperature controller and reliable remote monitoring that includes alert notifications.

Ultimately, furnace safety is a partnership between well-designed equipment and a well-informed operator.

Summary Table:

| Safety Category | Key Features | Purpose |

|---|---|---|

| Thermal Protection | Primary and secondary over-temperature alarms | Prevent overheating and equipment damage |

| Electrical Safeguards | Overcurrent protection | Mitigate fire risks and electrical failures |

| Operator Protection | Safety interlocks, gas flow monitors | Ensure user safety and prevent hazardous gas mixtures |

| Structural Safety | Refractory insulation | Contain heat and protect the environment |

Upgrade your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable solutions like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures these products precisely meet your unique experimental requirements, enhancing precision and reducing risks. Contact us today to discuss how we can support your specific sintering needs and deliver tailored safety features for peace of mind!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a potential drawback of rotary furnaces regarding warm-up time? Slow Heating Impacts Efficiency and Costs

- What optional features enhance the processing capabilities of rotary tube furnaces? Boost Efficiency with Advanced Customizations

- What are the benefits of a rotary tube furnace? Achieve Superior Uniformity and Efficiency

- What are rotary tube furnaces and their key features? Achieve Superior Uniform Heating for Powders

- What are the main components of a rotary furnace? Optimize Your High-Temp Processing

- Why is the rotary kiln significant in modern industry? Unlock Efficient, Large-Scale Material Processing

- What are the advantages of using a rotary kiln over other types of furnaces? Achieve Superior Uniformity and Efficiency

- How does the temperature control system work in a rotary tube furnace? Achieve Precise Thermal Processing for Your Materials