In short, advanced sealing technology directly improves rotary kiln performance by minimizing uncontrolled air leakage. This single action stabilizes internal temperatures, maintains the precise atmospheric conditions required for chemical reactions, and dramatically reduces fuel consumption, leading to significant cost savings and higher product quality.

A rotary kiln is fundamentally a controlled environment. Advanced seals protect the integrity of that environment, transforming the kiln from an inefficient, unpredictable system into a highly efficient and stable processing unit.

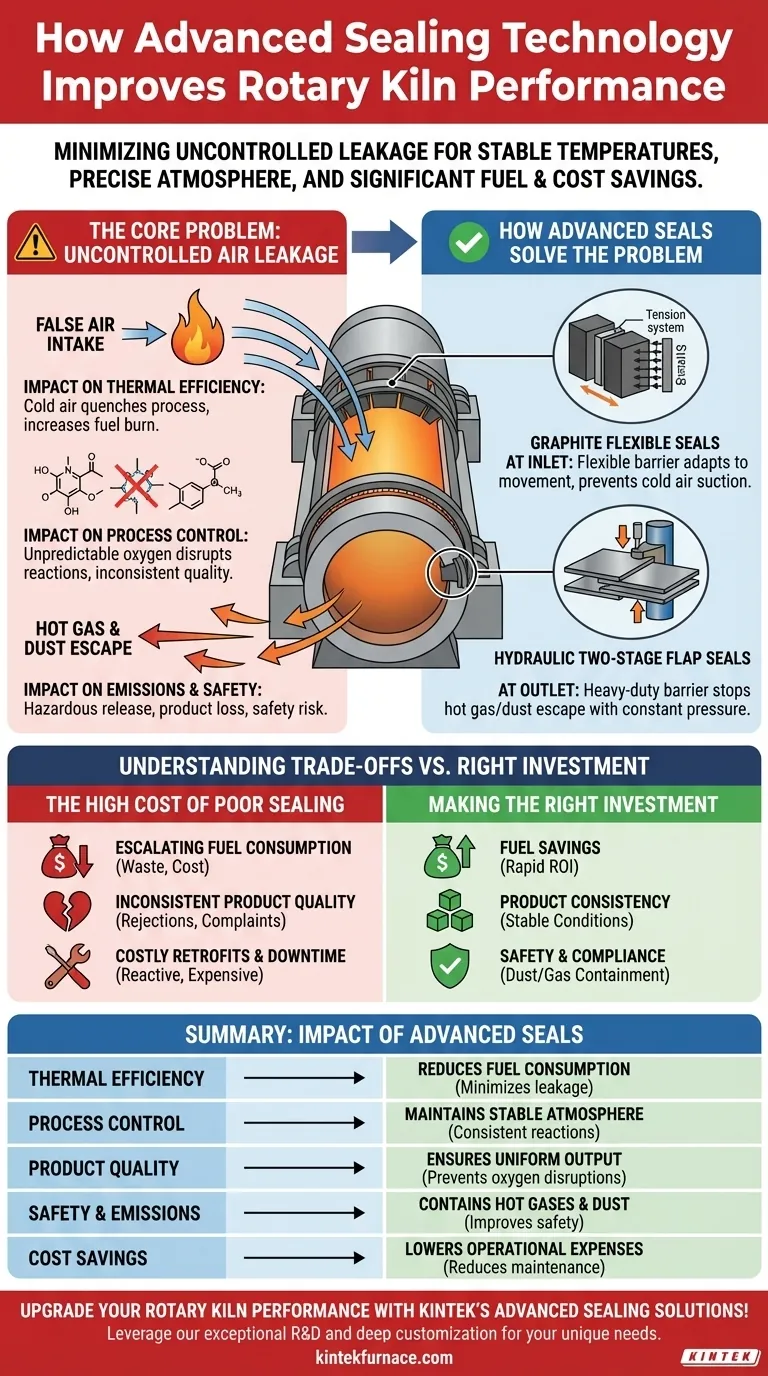

The Core Problem: Uncontrolled Air Leakage

The primary challenge in any rotary kiln operation is managing the flow of air and gases. A poor seal creates a state of constant compromise, undermining the entire process.

The Impact on Thermal Efficiency

A rotary kiln is designed to contain immense heat. When cold air leaks into the system—often called "false air"—it immediately quenches the process temperature.

The system's burner must then work significantly harder, consuming more fuel just to compensate for this incoming cold air and bring the temperature back to the required setpoint. This is the single largest source of energy waste in a poorly sealed kiln.

The Impact on Process Control

Many chemical processes within a kiln, such as lime production, require a specific atmosphere with controlled oxygen levels.

Uncontrolled air leakage introduces unpredictable amounts of oxygen, disrupting these delicate reactions. This leads to inconsistent product quality, reduced output, and wasted raw materials. The seal is crucial for preserving the controlled conditions necessary for effective processing.

The Impact on Emissions and Safety

Seals don't just prevent air from getting in; they prevent hot gas and dust from getting out.

Escaping hot gases are a safety hazard and an environmental concern. Furthermore, escaping dust represents a loss of valuable product and creates a hazardous work environment that requires costly cleanup.

How Advanced Seals Solve the Problem

Modern sealing systems are engineered to create a robust barrier between the rotating kiln shell and the stationary housing at both the inlet and outlet ends.

Graphite Flexible Seals

These seals often use blocks of graphite held in place by a tensioning system. The natural lubricating properties and high-temperature resistance of graphite allow it to press firmly against the rotating kiln shell.

This creates a tight, flexible barrier that can adapt to the minor movements and imperfections of the kiln, effectively preventing cold air from being sucked into the kiln feed end.

Hydraulic Two-Stage Flap Seals

Used at the kiln outlet, these heavy-duty systems use multiple layers of overlapping steel plates (flaps) to create a formidable barrier against escaping hot gas and dust.

A hydraulic system ensures constant, even pressure is applied to the flaps, maintaining the seal's integrity even under the harsh conditions of high temperature and high abrasion at the discharge end.

Understanding the Trade-offs of Poor Sealing

Ignoring a poor seal is not a cost-saving measure; it is an acceptance of ongoing, compounding losses that far outweigh the investment in a proper upgrade.

Escalating Fuel Consumption

The financial drain from wasted fuel is the most immediate and significant consequence. A kiln with significant air leakage can see its energy consumption increase dramatically, directly impacting operational profitability.

Inconsistent Product Quality

When process control is lost due to an unstable atmosphere, the final product quality suffers. This can lead to rejected batches, customer complaints, and damage to your operational reputation.

Costly Retrofits and Downtime

Eventually, the performance degradation caused by a poor seal becomes unsustainable. This forces a reactive, often emergency, upgrade. The resulting investment in new equipment, coupled with extended and unplanned renovation cycles, is far more expensive than proactive maintenance and upgrades.

Making the Right Investment in Sealing

Choosing to invest in advanced sealing technology is a strategic decision that pays dividends across multiple areas of your operation.

- If your primary focus is reducing operational costs: Prioritize sealing upgrades, as the immediate and drastic reduction in fuel consumption typically offers a rapid return on investment.

- If your primary focus is improving product consistency: An effective seal is non-negotiable for maintaining the stable thermal and atmospheric conditions required for high-quality, repeatable output.

- If your primary focus is enhancing safety and compliance: Modern seals are essential for containing process dust and hazardous gases, ensuring a safer workplace and adherence to environmental regulations.

Ultimately, viewing your kiln's sealing system as a foundational component, rather than a simple wear part, is the key to unlocking its full operational potential.

Summary Table:

| Aspect | Impact of Advanced Seals |

|---|---|

| Thermal Efficiency | Reduces fuel consumption by minimizing cold air leakage |

| Process Control | Maintains stable atmospheric conditions for consistent reactions |

| Product Quality | Ensures uniform output by preventing oxygen disruptions |

| Safety & Emissions | Contains hot gases and dust, improving workplace safety |

| Cost Savings | Lowers operational expenses and reduces maintenance downtime |

Upgrade your rotary kiln performance with KINTEK's advanced sealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnace systems like Rotary Furnaces with deep customization to meet your unique needs. Reduce fuel costs, enhance product consistency, and ensure safety—contact us today for a tailored solution!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes