At its core, the role of an indirect-fired rotary kiln in carbonization and activation is to provide an exceptionally controlled, oxygen-free processing environment. By heating the rotating kiln externally, it separates the combustion gases from the material being processed, which is the essential condition required to transform carbonaceous materials into high-purity charcoal or activated carbon rather than simply incinerating them into ash.

The defining advantage of an indirect-fired kiln is not just the heat it provides, but the atmosphere it protects. It allows for precise thermal processing in an oxygen-starved or specially formulated environment, which is non-negotiable for successful carbonization and activation.

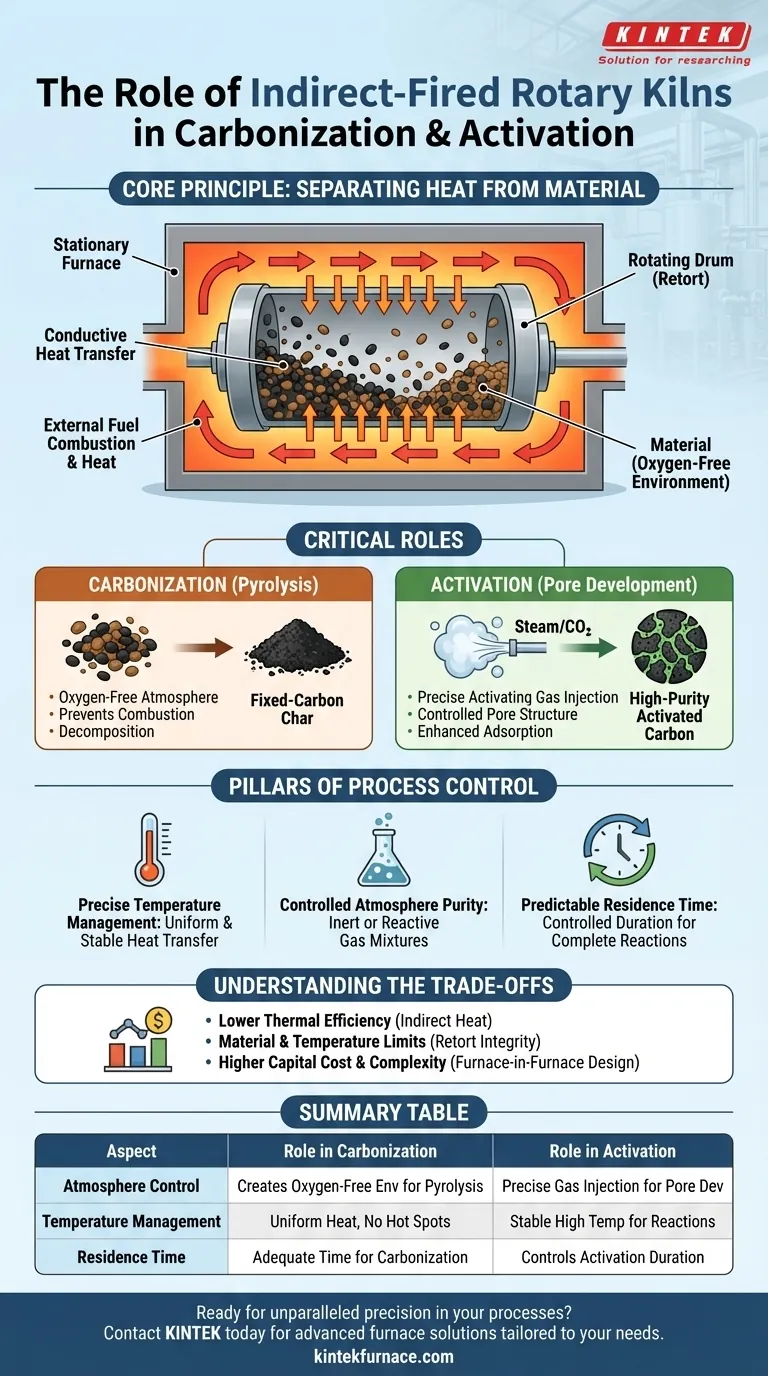

The Core Principle: Separating Heat from Material

To understand the kiln's role, you must first understand its fundamental design principle: the deliberate separation of the heat source from the process material.

How an Indirect-Fired Kiln Works

An indirect-fired rotary kiln consists of a rotating drum (the retort) that is fully enclosed within a larger, stationary furnace.

Fuel is burned within the outer furnace, heating the exterior of the rotating drum. This heat is then transferred by conduction through the drum's wall to the material tumbling inside. This design ensures the material never comes into contact with the flame or the combustion byproducts.

Why Separation is Critical for Carbonization

Carbonization is a form of pyrolysis—the thermal decomposition of materials at elevated temperatures in an inert or oxygen-starved atmosphere.

If the carbonaceous material were exposed to the oxygen-rich gases of direct combustion, it would simply burn. The indirect kiln's design creates the necessary oxygen-free environment, allowing the material to break down, release volatile compounds, and form a fixed-carbon char.

The Essential Role in Activation

Activation is the process that develops the vast internal pore structure of activated carbon, giving it its powerful adsorption capabilities.

This is typically achieved by exposing the carbonized material to an oxidizing agent like steam or carbon dioxide at high temperatures. An indirect kiln allows these activating gases to be injected into the drum in precise concentrations, without being diluted or contaminated by external combustion gases, ensuring consistent and targeted pore development.

The Pillars of Process Control

The separation of atmospheres is the foundation upon which other critical process control advantages are built. These capabilities are why this technology is chosen for high-value material transformation.

Precise Temperature Management

Because the kiln is heated externally, the drum shell reaches a uniform and stable temperature. This provides extremely consistent and gentle heat transfer to the entire material bed, preventing hot spots and ensuring uniform product quality.

Controlled Atmosphere Purity

The sealed internal environment gives operators total control. It can be filled with an inert gas like nitrogen for pure carbonization, or a specific reactive gas mixture (like steam) for controlled activation. This level of purity is impossible in a direct-fired system.

Predictable Residence Time

Like all rotary kilns, the combination of the drum's rotational speed and its angle of inclination precisely determines the residence time—how long the material spends inside the heated zone. This ensures that the carbonization or activation reactions proceed to completion.

Understanding the Trade-offs

While ideal for high-control processes, the indirect-fired design comes with inherent trade-offs that must be considered.

Thermal Efficiency

Transferring heat through the thick metal wall of a rotating drum is inherently less efficient than passing hot combustion gases directly through the material bed. This can lead to higher fuel consumption compared to direct-fired alternatives for a given throughput.

Material and Temperature Limitations

The rotating drum is subjected to immense thermal and mechanical stress. This necessitates the use of expensive, high-performance alloys and places a practical ceiling on the maximum achievable process temperatures, which are dictated by the retort's material integrity.

Capital Cost and Complexity

The "furnace-within-a-furnace" design is mechanically more complex than a direct-fired kiln. This generally results in higher initial capital investment and more demanding maintenance requirements.

Making the Right Choice for Your Goal

The decision to use an indirect-fired rotary kiln hinges entirely on your final product requirements and the level of process control you need.

- If your primary focus is producing high-purity char or activated carbon: The absolute atmospheric control offered by an indirect kiln is essential and non-negotiable.

- If your primary focus is developing a specific pore structure for adsorption: The ability to precisely manage the activating gas concentration makes an indirect kiln the superior choice.

- If your primary focus is simple bulk drying or volume reduction (not carbonization): The higher thermal efficiency and lower cost of a direct-fired kiln may be a more practical solution.

Ultimately, choosing an indirect-fired kiln is an investment in process control to achieve a level of product quality that other methods cannot guarantee.

Summary Table:

| Aspect | Role in Carbonization | Role in Activation |

|---|---|---|

| Atmosphere Control | Creates oxygen-free environment for pyrolysis, preventing combustion and forming fixed-carbon char. | Allows precise injection of activating gases (e.g., steam) without contamination for targeted pore development. |

| Temperature Management | Provides uniform heat transfer, preventing hot spots and ensuring consistent material breakdown. | Maintains stable high temperatures for controlled reactions, enhancing pore structure formation. |

| Residence Time | Ensures material spends adequate time in heated zone for complete carbonization reactions. | Controls duration for activation to optimize adsorption capabilities and product quality. |

Ready to achieve unparalleled precision in your carbonization and activation processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industrial applications. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed with strong deep customization capabilities to meet your unique experimental needs. Whether you're producing high-purity activated carbon or optimizing material transformations, our expertise ensures superior control and efficiency. Contact us today to discuss how we can elevate your process with reliable, customized solutions!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What contributes to the long service life of rotary kilns? Key Factors for Decades of Durability

- How does the drive assembly of a rotary kiln function? Key to Efficient Thermal Processing

- What role do rotary kilns play in catalyst production and recovery? Essential for Calcination and Sustainable Catalyst Lifecycle

- How does a rotary kiln function mechanically? Master Material Processing with Precision Engineering

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency