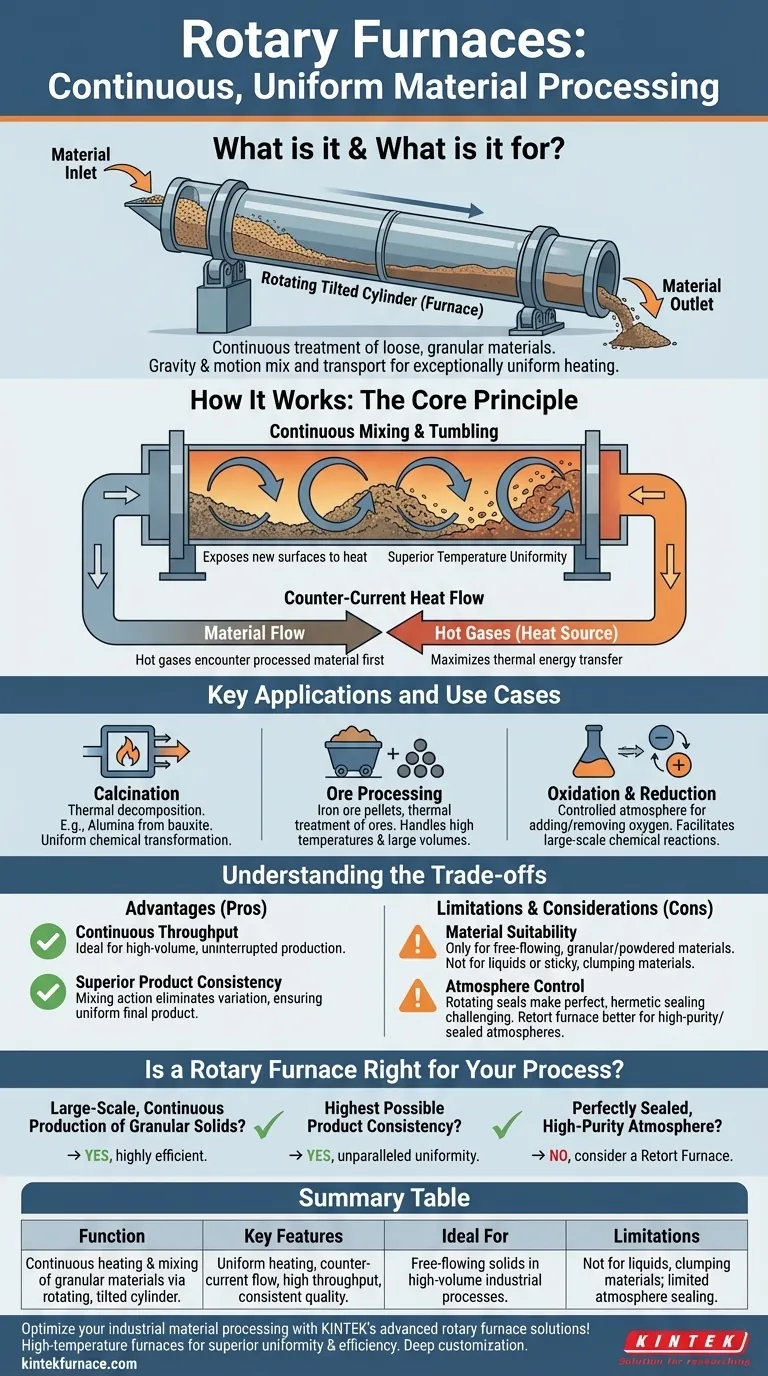

In high-temperature material processing, a rotary furnace is a specialized piece of equipment designed for the continuous treatment of loose, granular materials. It consists of a long, cylindrical tube that rotates on its axis while being slightly inclined, which uses gravity and motion to mix and transport materials from an inlet to an outlet, ensuring exceptionally uniform heating.

The core purpose of a rotary furnace is not just to heat material, but to do so continuously and uniformly. Its rotating, tilted design is engineered to tumble and mix bulk solids as they move through the furnace, guaranteeing consistent processing that is impossible to achieve in a static system.

The Core Principle: How a Rotary Furnace Works

A rotary furnace's effectiveness comes from its simple yet powerful mechanical design. The synergy between rotation, tilt, and heat flow creates a highly efficient processing environment.

The Rotating, Tilted Cylinder

The furnace is essentially a large, barrel-shaped tube that rotates slowly around its longitudinal axis.

This cylinder is installed at a slight angle to the horizontal. This tilt is critical, as it ensures that material fed into the higher end will gradually travel down to the lower end as the furnace turns.

The Benefit of Continuous Mixing

As the cylinder rotates, the material inside is continuously lifted and tumbled. This action, similar to clothes in a dryer, constantly exposes new surfaces to the heat source.

This tumbling motion is the key to achieving superior temperature uniformity. It prevents hot spots and ensures every particle undergoes the same thermal treatment, leading to a highly consistent end product.

Counter-Current Heat Flow

In most designs, heat is supplied by hot gases that flow in the opposite direction of the material. This is known as counter-current flow.

This method is highly efficient. The hottest gases encounter the most processed material near the discharge end, while the cooler, exiting gases preheat the fresh material at the inlet, maximizing thermal energy transfer.

Key Applications and Use Cases

The design of a rotary furnace makes it ideal for specific industrial processes that benefit from continuous throughput and uniform heating of solids.

Calcination

Calcination is a thermal decomposition process used to transform materials. A rotary furnace is exceptionally well-suited for this, such as in the production of alumina from bauxite.

The continuous mixing ensures that the chemical transformation happens uniformly throughout the bulk material.

Ore Processing

The manufacturing of iron ore pellets and the thermal treatment of other ores are common applications.

The furnace's ability to handle high temperatures and process large volumes makes it a cornerstone of the metals and mining industry.

Oxidation and Reduction

Processes that require adding or removing oxygen from a material can be performed effectively in a rotary furnace.

The atmosphere inside the furnace can be controlled to create an oxidizing or reducing environment, facilitating these chemical reactions on a large scale.

Understanding the Trade-offs

While powerful, a rotary furnace is a specialized tool. Understanding its advantages and limitations is crucial for proper application.

Advantage: Continuous Throughput

The most significant benefit is its suitability for continuous, high-volume production. Unlike a batch furnace that must be loaded and unloaded, a rotary furnace operates uninterrupted.

This makes it ideal for industrial plants where consistent output is a primary economic driver.

Advantage: Superior Product Consistency

The inherent mixing action virtually eliminates process variation. The result is a final product with a level of uniformity that static batch furnaces cannot match.

Limitation: Material Suitability

Rotary furnaces are designed for free-flowing, granular, or powdered materials.

They are not suitable for liquids, large single objects, or materials that become sticky and are prone to clumping, as this would impede flow and rotation.

Consideration: Atmosphere Control

While a rotary furnace can manage a controlled atmosphere, its design with rotating seals makes achieving a perfect, hermetic seal challenging.

For processes requiring extremely pure or specific sealed atmospheres (like a vacuum or high-purity inert gas), a retort furnace is often a better-suited alternative, as its primary design feature is a sealed chamber.

Is a Rotary Furnace Right for Your Process?

Choosing the correct furnace technology depends entirely on your material, scale, and processing goals.

- If your primary focus is large-scale, continuous production of granular solids: A rotary furnace is one of the most efficient and effective technologies available.

- If your primary focus is achieving the highest possible product consistency: The tumbling and mixing action of a rotary furnace offers unparalleled temperature uniformity for bulk materials.

- If your primary focus is processing under a perfectly sealed, high-purity atmosphere: You should evaluate a retort furnace, which is specifically engineered for that purpose.

Ultimately, understanding this technology empowers you to select the right tool for creating a consistent, high-quality product at an industrial scale.

Summary Table:

| Aspect | Details |

|---|---|

| Function | Continuous heating and mixing of granular materials via a rotating, tilted cylinder |

| Key Features | Uniform heating, counter-current heat flow, high throughput, consistent product quality |

| Common Applications | Calcination (e.g., alumina production), ore processing (e.g., iron pellets), oxidation/reduction |

| Ideal For | Free-flowing solids in high-volume industrial processes |

| Limitations | Not suitable for liquids, large objects, or materials that clump; limited atmosphere sealing |

Optimize your industrial material processing with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces, including Rotary Furnaces, designed for superior uniformity and efficiency. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our products can enhance your production consistency and scale!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials