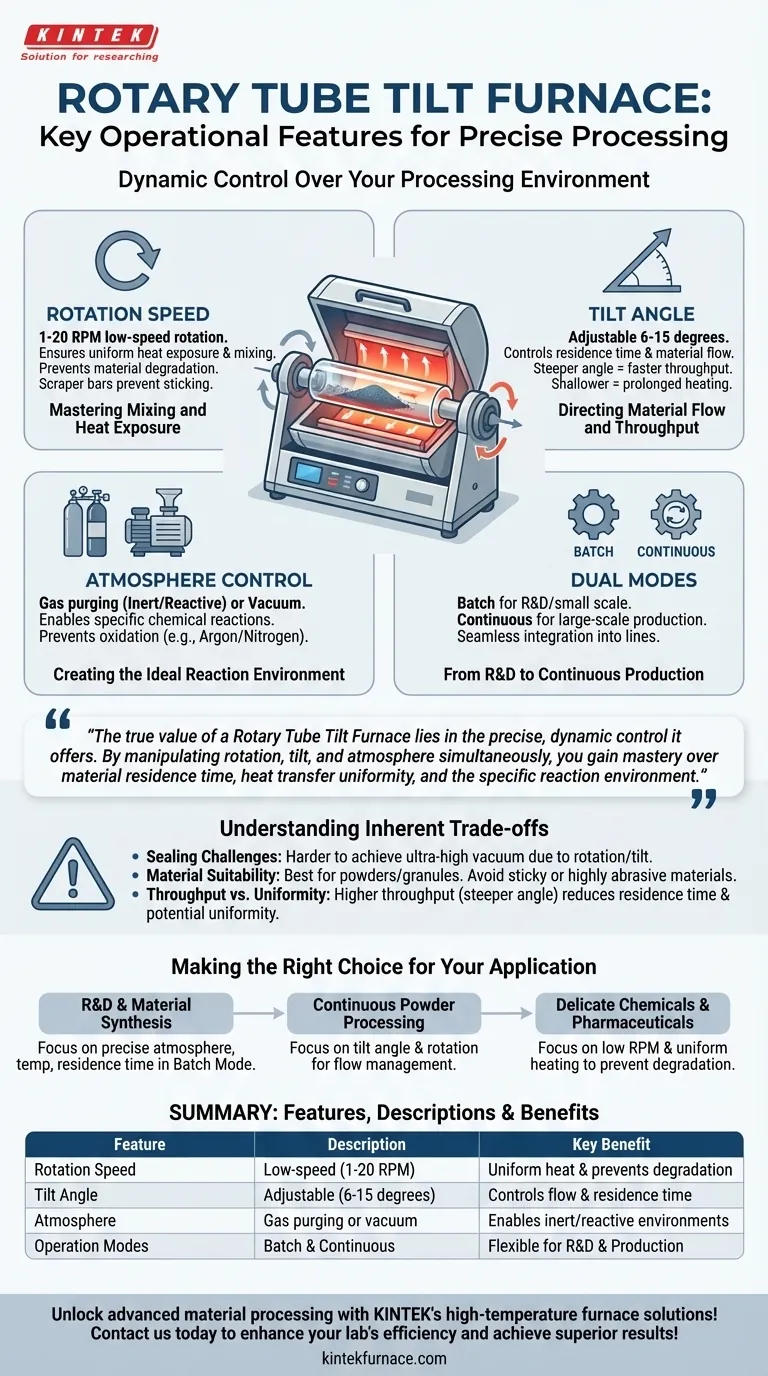

At its core, the Rotary Tube Tilt Furnace is defined by its dynamic control over the processing environment. Its key operational features are a low-speed rotation (1-20 RPM), an adjustable tilt angle (6-15 degrees), versatile atmosphere control (gas purging or vacuum), and the flexibility to operate in both batch and continuous modes. These features work in concert to provide precise command over how material is heated and transported.

The true value of a Rotary Tube Tilt Furnace lies not in any single feature, but in the precise, dynamic control it offers. By manipulating rotation, tilt, and atmosphere simultaneously, you gain mastery over material residence time, heat transfer uniformity, and the specific reaction environment.

How Key Features Control Your Process

Understanding this furnace requires seeing it as a complete system where each feature directly influences the final product. The goal isn't just to heat a material, but to transform it under specific, repeatable conditions.

Rotation Speed: Mastering Mixing and Heat Exposure

The slow rotation, typically between 1 and 20 RPM, is a critical design choice. This gentle tumbling action ensures that every particle of the material is uniformly exposed to the heat source, eliminating hot spots and ensuring consistent processing.

For delicate powders or granular materials, this low speed prevents degradation or particle breakdown. The inclusion of scraper bars inside the tube further enhances this process by preventing material from sticking to the tube wall and promoting thorough mixing.

Tilt Angle: Directing Material Flow and Throughput

The ability to adjust the furnace's tilt angle, usually from 6 to 15 degrees, directly controls the residence time of the material inside the hot zone.

A steeper angle results in a faster flow-through rate, ideal for continuous production or processes requiring shorter heat exposure. A shallower angle increases the time the material spends in the furnace, which is necessary for processes like calcination or sintering that require prolonged, thorough heating. This tilt function also makes discharging the final product simple and efficient.

Atmosphere Control: Creating the Ideal Reaction Environment

This furnace is not limited to heating in ambient air. Its design allows for advanced atmosphere control, which is essential for a wide range of chemical and material processes.

You can purge the tube with an inert gas like argon or nitrogen to prevent oxidation of sensitive materials. Alternatively, you can introduce reactive gases to facilitate specific chemical reactions or create a vacuum for processes that require it. This flexibility makes the furnace suitable for everything from catalyst activation to synthesizing advanced nanomaterials.

Dual Modes: From R&D to Continuous Production

The furnace's ability to operate in both batch and continuous modes makes it a highly versatile tool.

For research and development or small-scale production, batch mode allows for precise processing of a known quantity of material. For larger-scale industrial applications, the furnace can be integrated into a continuous production line, where raw material is constantly fed in one end and the processed product is discharged from the other.

Understanding the Inherent Trade-offs

No single piece of equipment is perfect for every task. The dynamic nature of a rotary tilt furnace introduces specific considerations that you must weigh against its benefits.

The Challenge of Sealing a Dynamic System

The rotating and tilting mechanisms create inherent challenges for achieving a perfect atmospheric seal. While excellent for controlled gas purging and low vacuums, achieving the ultra-high vacuum levels possible in a static furnace can be more complex and costly.

Material Suitability and Wear

The furnace excels with powders and fine granules. However, it may not be suitable for materials that are sticky, highly abrasive, or prone to agglomeration at high temperatures. Such materials can build up inside the tube, damage the internal scraper bars, or cause excessive wear on the tube itself.

Throughput vs. Uniformity

There is a direct trade-off between production speed and processing uniformity. Increasing the tilt angle to maximize throughput reduces the material's residence time. For some processes, this may not allow enough time for the desired thermal reaction or physical change to complete uniformly throughout the material.

Making the Right Choice for Your Application

To determine if this furnace meets your needs, align its core features with your primary processing goal.

- If your primary focus is R&D and material synthesis: The precise control over atmosphere, temperature, and residence time in batch mode is your most critical advantage.

- If your primary focus is continuous powder processing: The combination of tilt angle and rotation speed to manage material flow and throughput is the key feature for you.

- If your primary focus is processing delicate chemicals or pharmaceuticals: The gentle tumbling action of the low RPM range and uniform heating will prevent material degradation.

Ultimately, this furnace empowers you to move beyond simple heating and actively engineer your material's thermal processing journey.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Rotation Speed | Low-speed rotation (1-20 RPM) | Ensures uniform heat exposure and prevents material degradation |

| Tilt Angle | Adjustable angle (6-15 degrees) | Controls material flow and residence time for precise processing |

| Atmosphere Control | Gas purging or vacuum capabilities | Enables inert or reactive environments for various chemical reactions |

| Operation Modes | Batch and continuous modes | Supports R&D and large-scale production with flexibility |

Unlock advanced material processing with KINTEK's high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with rotary tube tilt furnaces and other systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency

- What is the role of rotary tube furnaces in the energy sector? Boost Efficiency in Biomass and Battery Material Processing

- What optional features enhance the processing capabilities of rotary tube furnaces? Boost Efficiency with Advanced Customizations

- What materials are rotary tube furnaces typically constructed from? Choose the Right Tube for Your Process

- In what environments are rotary tube furnaces considered indispensable? Essential for Uniform Thermal Processing