At its core, a rotary tube furnace is a system comprised of four primary components: the furnace body which provides structure and insulation, a central rotating tube that contains the material, a heating system that surrounds the tube, and a drive mechanism that controls the rotation. These elements are governed by a temperature control system to ensure precise and uniform thermal processing.

The essential purpose of a rotary tube furnace is not just to heat material, but to do so with exceptional uniformity. The synergy between the rotating tube and the stationary heating elements is the key design principle that enables consistent, dynamic, and controlled processing of powders and granular materials.

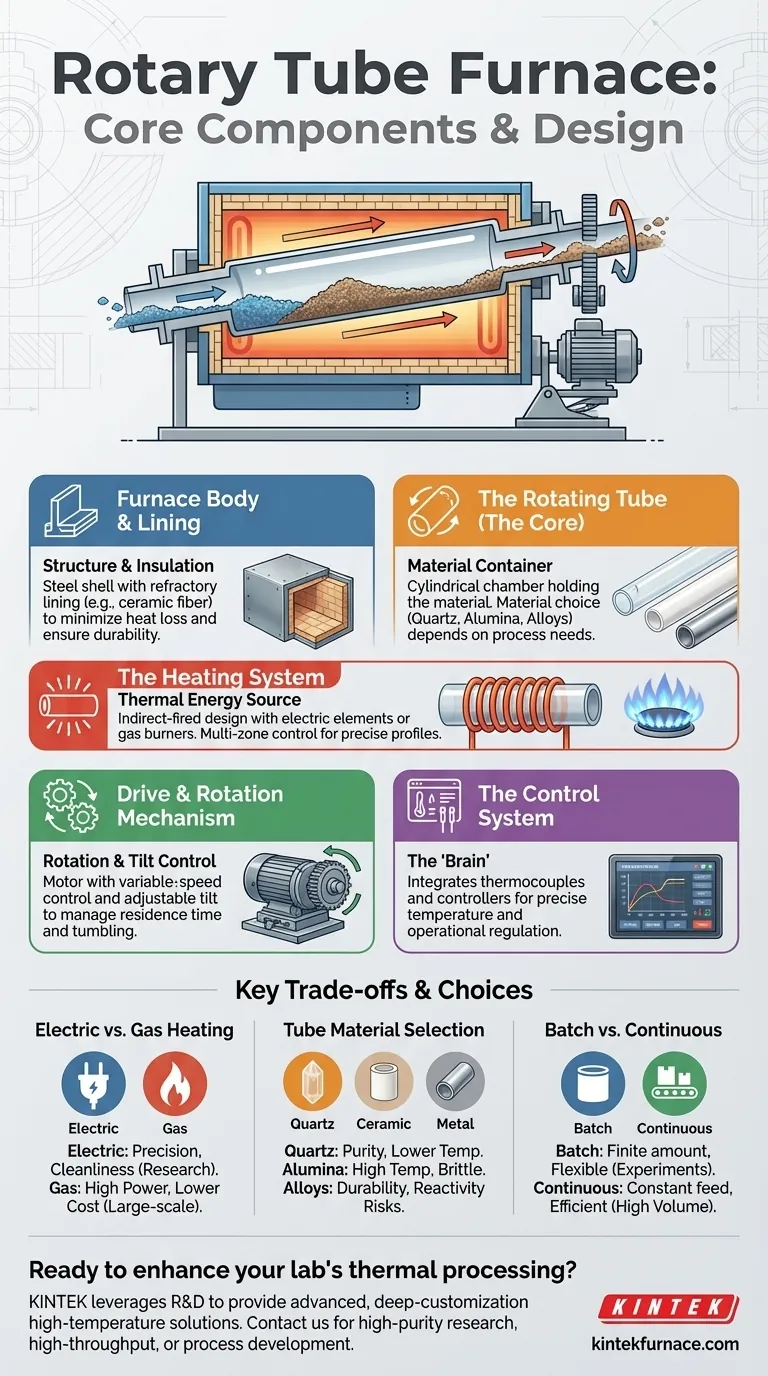

Deconstructing the Rotary Tube Furnace

To understand how a rotary tube furnace achieves its results, it is essential to examine the function of each individual component and how it contributes to the overall system.

The Furnace Body & Lining

The furnace body is the external steel structure that provides the physical framework and houses all other components. It is designed for high-temperature durability and structural integrity.

Inside this steel shell is a refractory lining, typically made of high-performance insulating bricks, moldable cement, or ceramic fiber. This lining is critical for minimizing heat loss, ensuring energy efficiency, and protecting the outer body from extreme internal temperatures.

The Rotating Tube (The Core)

The central component is the furnace tube, a cylindrical chamber that rotates on its central axis. This tube is where the material being processed is actually held. It is distinct from the furnace body that surrounds it.

The material of the tube itself is chosen based on the process requirements, with common options including quartz for purity, alumina for very high temperatures, or specialized metal alloys for durability and chemical resistance.

The Heating System

The heating system provides the thermal energy. It typically consists of electric heating elements or gas burners positioned around the exterior of the rotating tube.

This is known as an indirect-fired design. The heat source does not directly contact the process material, which prevents contamination and allows for precise control over the atmosphere inside the tube. Advanced models feature multiple thermal control zones along the length of the tube, enabling highly customized temperature profiles for complex processes like drying, calcination, and synthesis.

The Drive & Rotation Mechanism

The drive mechanism is what enables the tube's rotation. This system usually consists of a motor connected to a drive gear or a set of driven rollers that support and turn the tube.

Key features often include variable-speed control and the ability to adjust the tilt angle. Changing the rotation speed and tilt directly influences how long the material stays in the furnace (its residence time) and how it tumbles, providing critical control over the process.

The Control System

The control system is the brain of the furnace. It integrates temperature sensors (thermocouples) with a controller to precisely regulate the heating elements, ensuring the process temperature remains stable and accurate. This system also manages the rotation speed and other operational parameters.

Understanding the Key Trade-offs

Choosing the right rotary tube furnace involves balancing competing factors. Understanding the trade-offs between different component options is critical for matching the furnace to its intended application.

Electric vs. Gas Heating

Electric heating elements offer superior temperature precision, cleanliness, and ease of control, making them ideal for high-purity applications and research.

Gas-fired systems can often achieve higher power outputs and may have lower operating costs for large-scale industrial processes, but they introduce products of combustion that may require more complex atmospheric management.

Tube Material Selection

The choice of tube material presents a classic trade-off between performance and cost. A quartz tube offers excellent purity but has a lower maximum operating temperature compared to ceramics.

An alumina tube can withstand much higher temperatures but may be more brittle. Metal alloy tubes provide excellent mechanical durability but can react with certain process materials or atmospheres at high temperatures.

Batch vs. Continuous Processing

Rotary tube furnaces are uniquely suited for continuous processing, where material is constantly fed into one end and discharged from the other. This is highly efficient for large volumes.

However, they can also be used for batch processing, where a finite amount of material is loaded, processed, and then removed. The optimal configuration depends entirely on the required throughput and the nature of the experiment or production run.

Making the Right Choice for Your Goal

Your specific process dictates the ideal furnace configuration. The interplay between the components determines the furnace's capabilities.

- If your primary focus is high-purity research and synthesis: Opt for a multi-zone electric furnace with a high-purity quartz or alumina tube for precise, clean, and repeatable thermal profiles.

- If your primary focus is high-throughput bulk material processing: A larger, continuous-feed furnace, potentially gas-fired with a durable metal alloy tube, will be the most cost-effective and efficient solution.

- If your primary focus is process development and flexibility: Prioritize a furnace with variable-speed rotation, adjustable tilt, and an easily interchangeable tube design to accommodate a wide range of materials and experiments.

By understanding each component's role, you can move from simply using a furnace to intelligently designing a complete thermal processing solution.

Summary Table:

| Component | Key Function | Common Options |

|---|---|---|

| Furnace Body & Lining | Provides structure and insulation, minimizes heat loss | Steel shell with refractory lining (e.g., ceramic fiber) |

| Rotating Tube | Holds and tumbles material for uniform processing | Quartz, alumina, or metal alloys |

| Heating System | Supplies thermal energy indirectly to prevent contamination | Electric elements or gas burners with multi-zone control |

| Drive & Rotation Mechanism | Controls tube rotation speed and tilt angle | Motor with variable-speed and adjustable tilt |

| Control System | Regulates temperature and operational parameters | Integrated with thermocouples and controllers |

Ready to enhance your lab's thermal processing with a custom rotary tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on high-purity research, high-throughput processing, or flexible process development, we can help you achieve superior results. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing