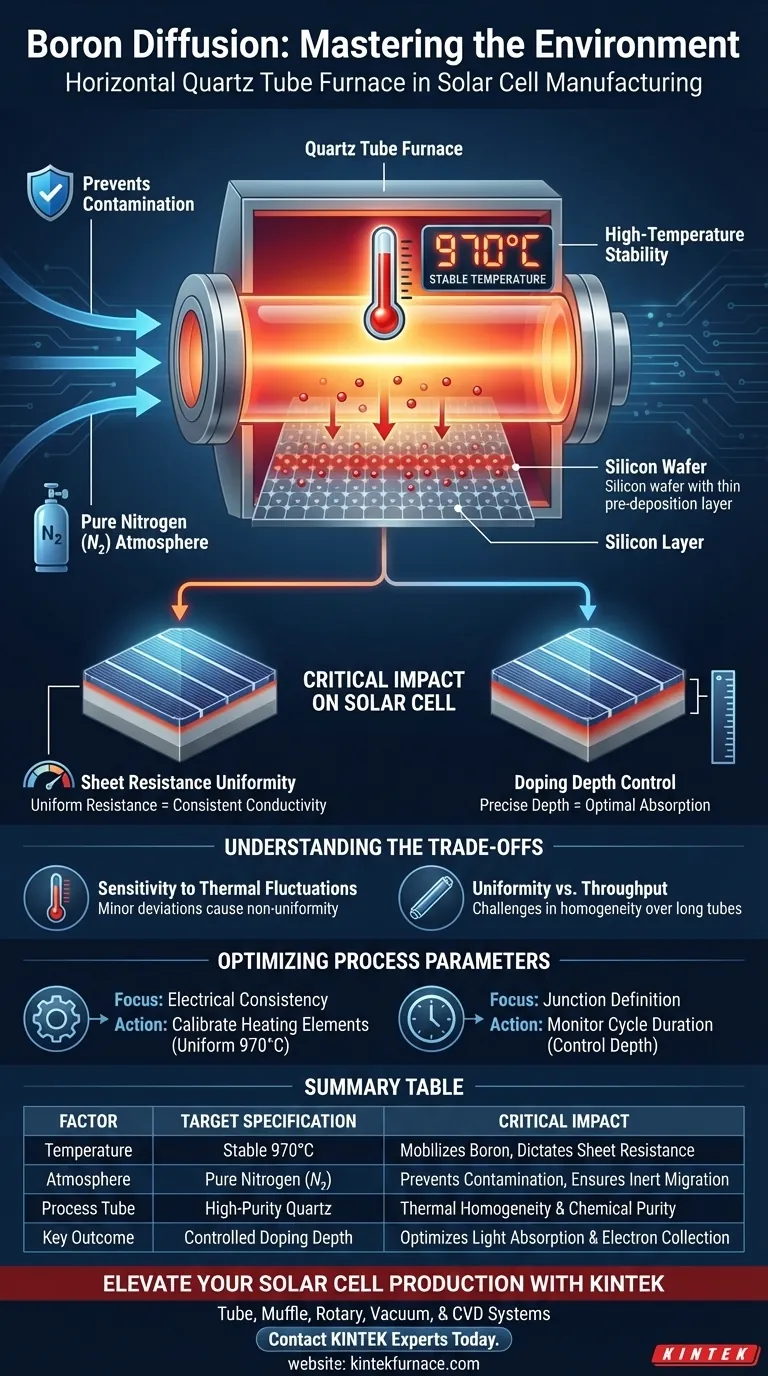

A horizontal quartz tube furnace specifically creates a rigorous thermal environment characterized by a stable temperature of approximately 970°C and a pure nitrogen atmosphere. These specific conditions are engineered to facilitate the migration of boron atoms from a pre-deposition layer into the silicon substrate, a critical step in forming the solar cell's emitter region.

Precision in thermal management is the primary driver of emitter quality. By maintaining a strict high-temperature nitrogen environment, the furnace ensures the uniformity of sheet resistance and the accuracy of doping depth essential for efficient solar cells.

The Critical Environmental Factors

High-Temperature Stability

The core function of the furnace is to reach and maintain a target temperature of 970°C. This specific thermal energy level is required to mobilize boron atoms.

Without this precise heat, the boron cannot diffuse effectively from the surface layer into the silicon lattice.

The Nitrogen Atmosphere

The diffusion process takes place within a controlled nitrogen environment. This inert atmosphere is crucial for isolating the wafers during the high-heat cycle.

It ensures that the boron migration occurs without interference from oxygen or other atmospheric contaminants that could degrade the silicon surface.

Impact on Solar Cell Architecture

Determining Sheet Resistance

The furnace's ability to hold the temperature at exactly 970°C directly dictates the sheet resistance uniformity of the final product.

Uniform resistance across the wafer is necessary for consistent electrical conductivity. Variations in temperature will lead to variations in resistance, impacting the cell's output.

Controlling Doping Depth

The thermal environment also defines the doping depth of the emitter. The depth is a function of how long the silicon is exposed to the 970°C heat.

Precise control allows manufacturers to achieve the exact junction depth required for optimal light absorption and electron collection.

Understanding the Trade-offs

Sensitivity to Thermal Fluctuations

The primary trade-off in this process is the extreme sensitivity to temperature variations.

Because the diffusion rate is exponentially dependent on temperature, even minor deviations from the 970°C setpoint can cause significant non-uniformity.

Uniformity vs. Throughput

Maintaining perfect environmental homogeneity across a long horizontal tube can be challenging, especially when processing large batches.

If the nitrogen flow or temperature gradient varies along the length of the tube, wafers at different positions may exhibit different electrical properties.

Optimizing Process Parameters

To achieve the best results with a horizontal quartz tube furnace, align your operational focus with your specific manufacturing goals:

- If your primary focus is Electrical Consistency: Prioritize the calibration of heating elements to ensure the 970°C temperature is uniform across the entire length of the tube.

- If your primary focus is Junction Definition: Strictly monitor the duration of the cycle under the nitrogen atmosphere to control the exact doping depth.

Success in boron diffusion ultimately relies on the absolute precision of your thermal and atmospheric controls.

Summary Table:

| Environmental Factor | Target Specification | Critical Impact on Solar Cell |

|---|---|---|

| Temperature | Stable 970°C | Mobilizes boron atoms & dictates sheet resistance |

| Atmosphere | Pure Nitrogen ($N_2$) | Prevents contamination & ensures inert boron migration |

| Process Tube | High-purity Quartz | Maintains thermal homogeneity & chemical purity |

| Key Outcome | Controlled Doping Depth | Optimizes light absorption and electron collection |

Elevate Your Solar Cell Production with KINTEK

Precision thermal management is the difference between a standard cell and a high-efficiency power source. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of semiconductor and solar manufacturing.

Whether you need custom dimensions or specific atmospheric controls for boron diffusion, our lab high-temp furnaces are customizable to your unique research or production needs.

Ready to achieve perfect sheet resistance and doping uniformity?

Visual Guide

References

- Hakim Korichi, Ahmed Baha-Eddine Bensdira. Investigating the influence of boron diffusion temperature on the performance of n-type PERT monofacial solar cells with reduced thermal steps. DOI: 10.35784/iapgos.6599

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a Vacuum Tube Furnace play in NPCu annealing? Achieve Precise Structural Homogenization

- Why is annealing in a tube furnace essential for rGO-NiO-ZnO-400? Optimize Your Catalyst Synthesis

- What are the advantages of using a tube furnace with nitrogen flow? Precision Engineering for High-Temp Pyrolysis

- What makes tube furnaces indispensable in academic and industrial settings? Unlock Precision Heating for Advanced Materials

- What industrial applications commonly use tube furnaces? Achieve Precise Heating for Advanced Manufacturing

- What are the main components of an atmosphere tube furnace? Unlock Precision in Material Processing

- What factors should be considered when choosing a tube furnace? Key Selection Criteria for Optimal Performance

- What is the role of programmed temperature control in a tube furnace? Optimize N-GC-X Catalyst Synthesis