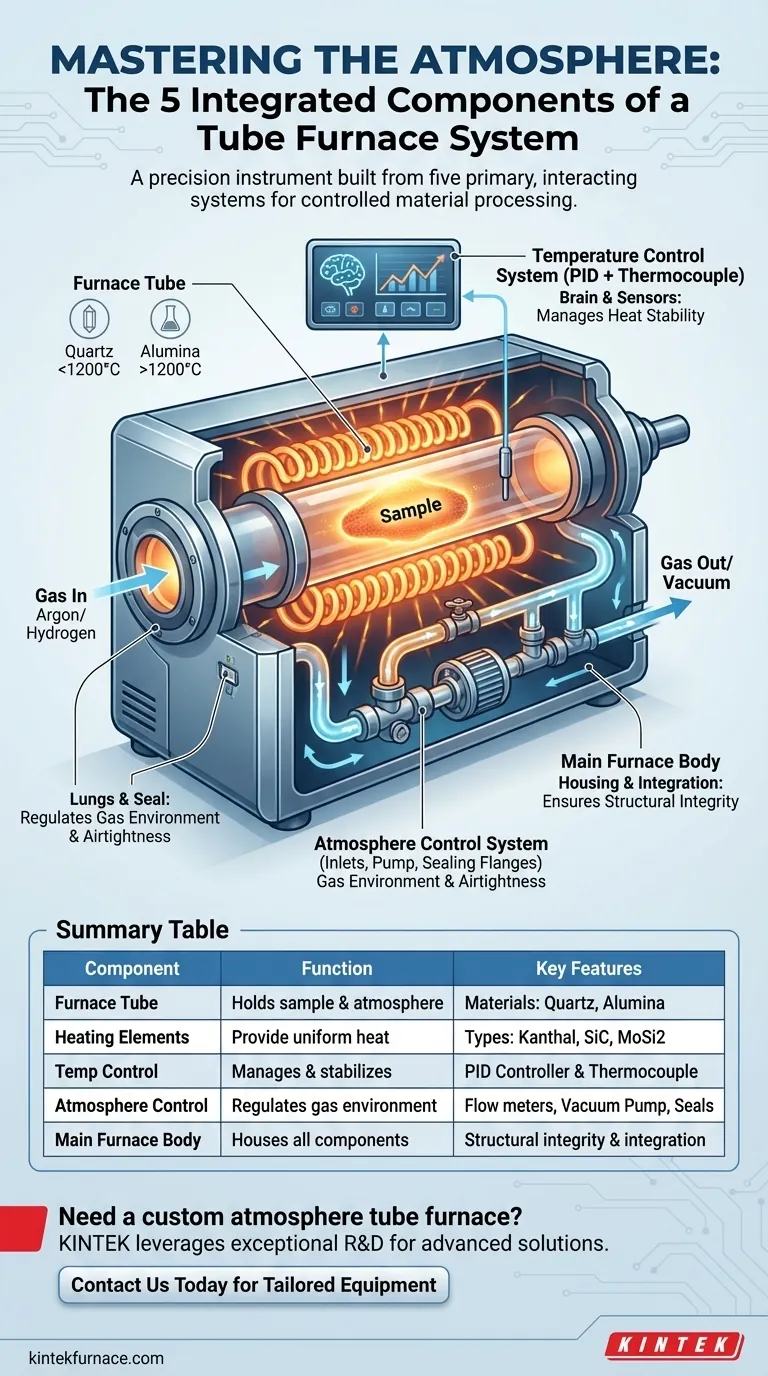

At its core, an atmosphere tube furnace is a precision instrument built from five primary systems. These are the furnace tube that contains the sample, the heating elements that surround it, a temperature control system to manage heat, an atmosphere control system to manage the internal gas environment, and the main furnace body that houses these components.

The critical takeaway is that these components are not independent parts, but an integrated system. The value of an atmosphere tube furnace lies in its ability to simultaneously and precisely control both temperature and chemical environment, preventing unwanted reactions like oxidation during material processing.

How the Core Components Function as a System

An atmosphere tube furnace is designed to create a highly controlled environment. Each component plays a specific role, and their seamless interaction is what makes precise materials processing possible.

The Furnace Tube: The Heart of the Operation

The furnace tube is the central chamber where the work happens. It holds the material sample and contains the controlled atmosphere.

The material of this tube is critical. Quartz is common for its transparency and chemical inertness at temperatures up to around 1200°C. For higher temperatures, alumina or other ceramic tubes are used, offering stability but sacrificing visibility.

The Heating Elements: Delivering Precise Thermal Energy

Wrapped around the outside of the furnace tube are the heating elements. These are typically made of high-resistance materials like Kanthal wire or, for higher temperatures, silicon carbide (SiC) or molybdenum disilicide (MoSi2) rods.

Their function is to convert electrical energy into radiant heat. The quality of the furnace is often determined by how uniformly these elements can heat the "hot zone" within the tube.

The Temperature Control System: The Brains of the Furnace

This system ensures the furnace reaches and maintains the exact desired temperature. It consists of a thermocouple (a sensor that measures temperature inside the furnace, often near the tube's outer wall) and a PID controller.

The PID (Proportional-Integral-Derivative) controller is the "brain." It reads the thermocouple's data and intelligently adjusts the power sent to the heating elements to prevent overshooting the target temperature and maintain stability.

The Atmosphere Control System: The Lungs and Seal

This is what distinguishes an atmosphere furnace from a standard one. This system allows you to remove the ambient air (which contains ~21% oxygen) and replace it with a specific gas.

It includes gas inlets and outlets, flow meters to regulate the gas supply (e.g., inert Argon or reducing Hydrogen), and a vacuum pump to first evacuate the air. Most importantly, it relies on sealing flanges at both ends of the tube to create an airtight environment and prevent contamination from the outside.

Understanding the Trade-offs and Limitations

While powerful, these furnaces are not without their complexities. The choices you make in their configuration involve direct trade-offs that impact performance and cost.

Material Selection vs. Temperature

The choice of furnace tube material directly dictates your maximum operating temperature. A quartz tube is relatively inexpensive but is limited to ~1200°C. An alumina tube can reach 1700°C or more but is more expensive and brittle.

Sealing Integrity vs. Operational Speed

Achieving a perfect, high-vacuum seal is critical for high-purity applications. However, this often involves complex flange assemblies that can be time-consuming to set up and disassemble between runs. A simple seal is faster but may allow trace amounts of atmospheric leakage.

Uniform Hot Zone vs. Furnace Size

The "hot zone" is the central portion of the tube that maintains a highly uniform temperature. A larger hot zone allows for processing bigger samples or more material at once, but this requires a longer furnace, more powerful heating elements, and a higher cost.

Making the Right Choice for Your Goal

Your application's specific requirements should dictate the furnace's configuration.

- If your primary focus is high-purity processing: Prioritize a system with high-quality vacuum-tight sealing flanges and a non-reactive tube material like high-purity quartz.

- If your primary focus is high-temperature annealing: You will need a furnace with an alumina tube and robust heating elements capable of reaching your target temperature.

- If your primary focus is creating a reducing environment: Ensure the atmosphere control system and seals are rated for use with flammable gases like hydrogen and include appropriate safety interlocks.

- If your primary focus is general inert atmosphere work: A standard configuration with a quartz tube and reliable flange seals will be sufficient and cost-effective.

Understanding how each component contributes to the final environment empowers you to select and operate the right tool for your specific scientific or industrial goal.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Tube | Holds sample and controlled atmosphere | Materials: Quartz (up to 1200°C), Alumina (higher temps) |

| Heating Elements | Provide uniform heat | Types: Kanthal, SiC, MoSi2 for precise thermal energy |

| Temperature Control | Manages and stabilizes temperature | Includes thermocouple and PID controller for accuracy |

| Atmosphere Control | Regulates internal gas environment | Gas inlets/outlets, flow meters, vacuum pump, sealing flanges |

| Main Furnace Body | Houses all components | Ensures structural integrity and system integration |

Need a custom atmosphere tube furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your material processing with tailored, reliable equipment!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity