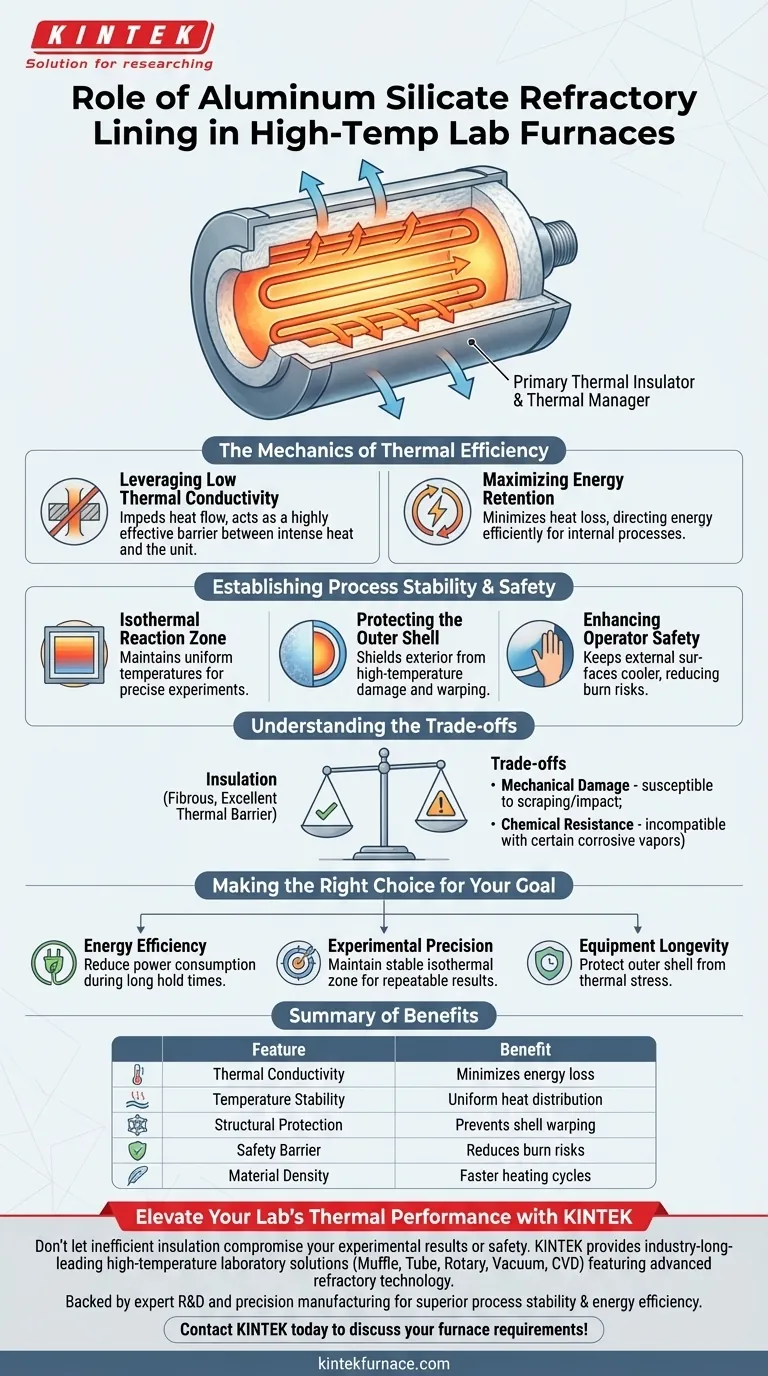

The aluminum silicate refractory lining serves as the primary thermal insulator in high-temperature laboratory furnaces. Wrapped directly around the heating elements, it utilizes its exceptionally low thermal conductivity to isolate the heat source, ensuring that energy is directed efficiently into the reaction chamber rather than escaping into the surrounding environment.

The lining acts as the furnace's thermal manager: it locks heat inside to stabilize internal reaction conditions while simultaneously shielding the outer shell and operator from dangerous temperatures.

The Mechanics of Thermal Efficiency

Leveraging Low Thermal Conductivity

The core function of aluminum silicate is to impede heat flow. Because this material has very low thermal conductivity, it acts as a highly effective barrier between the intense heat of the elements and the rest of the unit.

Maximizing Energy Retention

By wrapping the lining around the heating elements, the design minimizes heat loss to the external environment. This ensures that the energy consumed by the furnace is used primarily for the internal process, significantly enhancing the overall thermal efficiency of the system.

Establishing Process Stability and Safety

Creating an Isothermal Reaction Zone

Beyond simple insulation, the lining is essential for precision. It helps establish and maintain a stable isothermal reaction zone, ensuring that temperatures remain uniform throughout the specific area where experiments or processing occur.

Protecting the Outer Shell

The lining serves a critical safety function by lowering the temperature that reaches the furnace's exterior. This protects the outer furnace shell from high-temperature damage and warping, ensuring the structural integrity of the unit over time.

Enhancing Operator Safety

By containing the heat, the lining keeps the external surfaces cooler. This reduces the risk of burns to operators and prevents the surrounding laboratory equipment from being affected by excessive radiant heat.

Understanding the Trade-offs

Material Durability vs. Insulation

While aluminum silicate is excellent for insulation, it is a fibrous material. Unlike dense refractory bricks, fibrous linings can be susceptible to mechanical damage if scraped or impacted during loading and unloading.

Chemical Resistance

It is important to note that while thermally robust, refractory linings can interact with certain corrosive vapors at high temperatures. Users must ensure their specific chemical processes are compatible with aluminum silicate to avoid degrading the insulation over time.

Making the Right Choice for Your Goal

To maximize the utility of your laboratory furnace, consider how the lining aligns with your specific operational needs:

- If your primary focus is Energy Efficiency: Rely on the lining's low thermal conductivity to reduce power consumption during long hold times.

- If your primary focus is Experimental Precision: Ensure the lining is intact and uniform to maintain the stable isothermal zone required for repeatable results.

- If your primary focus is Equipment Longevity: Inspect the lining regularly to ensure it continues to protect the outer shell from thermal stress and warping.

A well-maintained refractory lining is the defining factor between a furnace that fluctuates unpredictably and one that delivers precise, safe, and efficient performance.

Summary Table:

| Feature | Role of Aluminum Silicate Lining | Benefit for Laboratory Operations |

|---|---|---|

| Thermal Conductivity | Exceptionally low heat transfer | Minimizes energy loss and lowers power consumption |

| Temperature Stability | Creates an isothermal reaction zone | Ensures uniform heat distribution for repeatable results |

| Structural Protection | Shields the outer furnace shell | Prevents shell warping and extends equipment lifespan |

| Safety Barrier | Keeps external surfaces cooler | Reduces burn risks and protects surrounding lab gear |

| Material Density | Lightweight fibrous composition | Facilitates faster heating cycles and better thermal response |

Elevate Your Lab's Thermal Performance with KINTEK

Don’t let inefficient insulation compromise your experimental results or safety. KINTEK provides industry-leading high-temperature laboratory solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems—all featuring advanced refractory technology and customizable designs to meet your specific research needs.

Backed by expert R&D and precision manufacturing, we help you achieve superior process stability and energy efficiency.

Contact KINTEK today to discuss your furnace requirements!

Visual Guide

References

- Garikai T. Marangwanda, Daniel M. Madyira. Evaluating Combustion Ignition, Burnout, Stability, and Intensity of Coal–Biomass Blends Within a Drop Tube Furnace Through Modelling. DOI: 10.3390/en18061322

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What protective mechanism does MoSi2 employ in oxidizing atmospheres? Discover Its Self-Healing Silica Layer

- How is grain growth in MoSi2 heating elements prevented? Boost Lifespan with Additive Engineering

- What are the properties and applications of Molybdenum (Mo) in heating elements? Choose the Right Element for High-Temp Success

- How does the thermal conductivity of silicon carbide heating elements improve process efficiency? Boost Speed and Uniformity

- What materials are typically used in the construction of high temperature heating elements? Discover the Best Options for Your Needs

- What materials are commonly used in heating elements and why? Discover the Best Choices for Your Thermal Systems

- What functions do graphite molds serve during the SPS of Barium Titanate? Optimize Heating and Pressure Transmission

- What is the function of ceramic washers in SWCNT-BNNT synthesis? Elevate Your Nanomaterial Precision