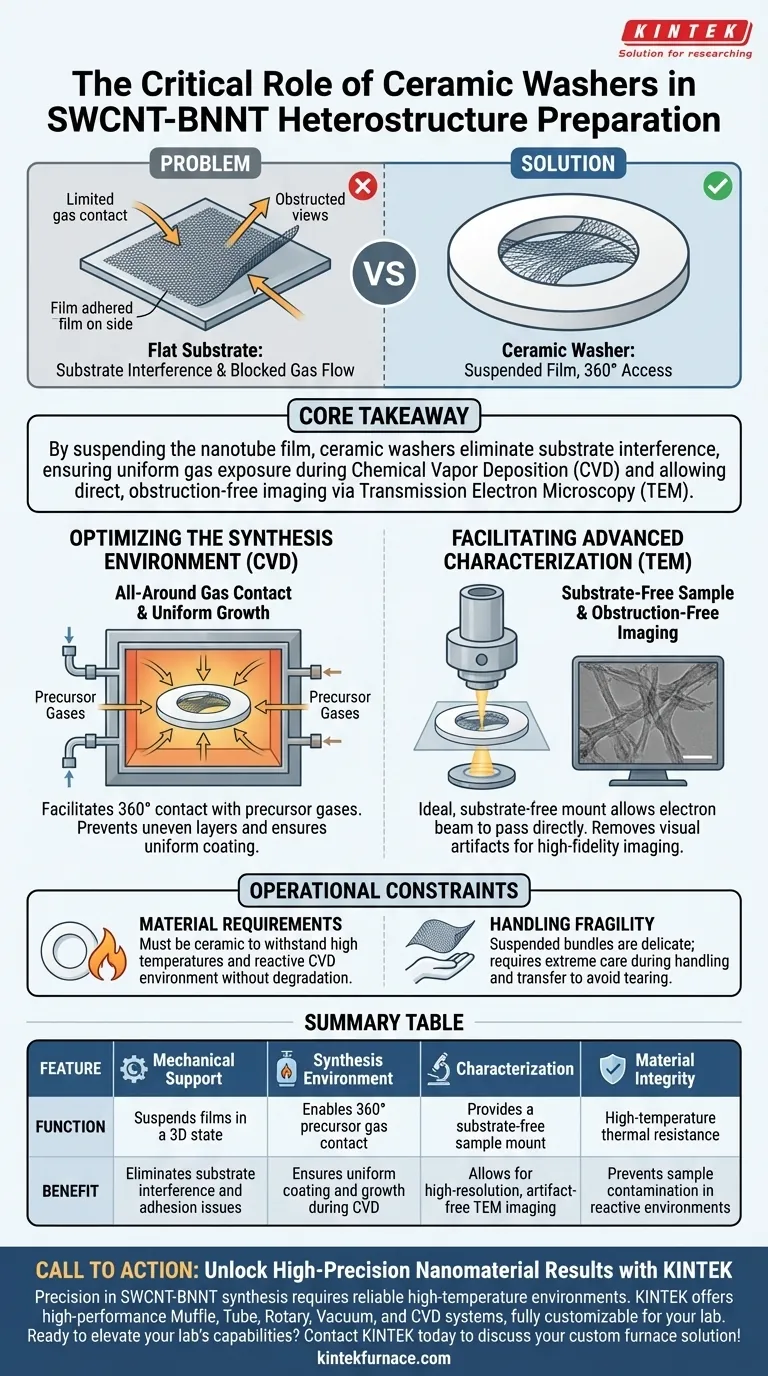

Ceramic washers serve as critical mechanical supports that hold Single-Walled Carbon Nanotube-Boron Nitride Nanotube (SWCNT-BNNT) films in a suspended state. By mounting the film on the washer, you ensure the nanotube bundles remain elevated rather than adhered to a solid backing, which fundamentally alters both the synthesis quality and the ability to characterize the material.

Core Takeaway By suspending the nanotube film, ceramic washers eliminate substrate interference during both synthesis and analysis. This configuration ensures uniform gas exposure during Chemical Vapor Deposition (CVD) and allows for direct, obstruction-free imaging via Transmission Electron Microscopy (TEM).

Optimizing the Synthesis Environment

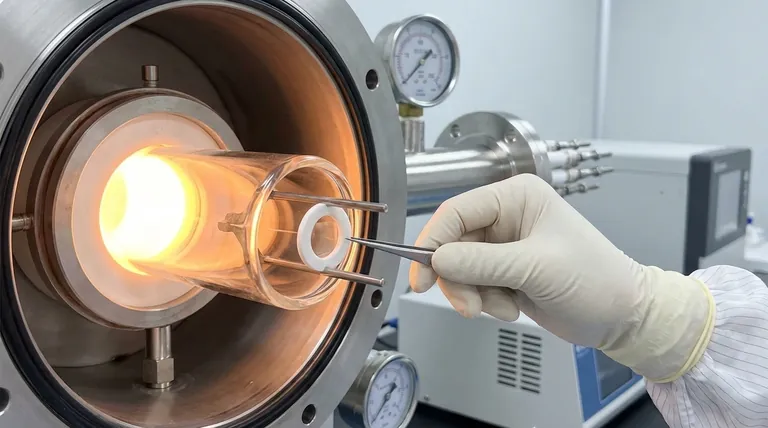

To understand the value of the ceramic washer, you must look at how it improves the Chemical Vapor Deposition (CVD) process.

Enabling All-Around Gas Contact

When a nanotube film is placed on a solid substrate, one side is blocked from the reaction.

The ceramic washer suspends the SWCNT-BNNT film, exposing it fully to the environment. This facilitates all-around contact with precursor gases during the CVD process.

Ensuring Uniform Growth

Because the precursor gases can access the nanotube bundles from all directions, the coating or growth process is more uniform.

This prevents the formation of uneven layers that typically occur when a sample is shielded by a flat substrate.

Facilitating Advanced Characterization

Beyond synthesis, the ceramic washer acts as a specialized mount for high-resolution imaging.

Creating a Substrate-Free Sample

Transmission Electron Microscopy (TEM) works best when the electron beam passes through the sample without resistance.

Standard substrates can scatter the beam or create background noise. The ceramic washer provides an ideal, substrate-free sample, allowing the beam to pass directly through the suspended nanotubes.

Removing Observation Interference

Direct observation is critical for verifying the structure of heterostructures.

By using the washer to suspend the film, researchers can observe the SWCNT-BNNT bundles without the visual interference or artifacts caused by underlying support materials.

Understanding the Operational Constraints

While the ceramic washer offers significant advantages, it introduces specific operational considerations.

Material Requirements

The washer must be ceramic rather than metal or plastic.

This is because the support structure must withstand the high temperatures and reactive environment of the CVD process without degrading or contaminating the sample.

Handling Fragility

Suspending a nanotube film makes it mechanically more vulnerable than a film supported by a solid silicon wafer.

While the washer provides a frame, the suspended bundles themselves are delicate. Great care is required during handling and transfer to the microscope to avoid tearing the suspended film.

Making the Right Choice for Your Goal

The use of ceramic washers is a strategic choice depending on whether your priority is structural uniformity or imaging clarity.

- If your primary focus is Synthesis Quality: The washer is essential for ensuring precursor gases reach the entire surface area of the nanotubes for uniform coating.

- If your primary focus is Characterization: The washer is the most effective tool for generating substrate-free samples required for high-fidelity TEM imaging.

Ultimately, the ceramic washer transforms the sample from a flat, supported film into a suspended 3D structure, unlocking both uniform growth and artifact-free observation.

Summary Table:

| Feature | Function of Ceramic Washer | Benefit to Research |

|---|---|---|

| Mechanical Support | Suspends films in a 3D state | Eliminates substrate interference and adhesion issues |

| Synthesis Environment | Enables 360-degree precursor gas contact | Ensures uniform coating and growth during CVD |

| Characterization | Provides a substrate-free sample mount | Allows for high-resolution, artifact-free TEM imaging |

| Material Integrity | High-temperature thermal resistance | Prevents sample contamination in reactive environments |

Unlock High-Precision Nanomaterial Results with KINTEK

Precision in SWCNT-BNNT synthesis requires reliable high-temperature environments and specialized equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs.

Whether you are scaling up 1D heterostructure production or optimizing characterization quality, our specialized furnaces provide the thermal stability essential for sensitive ceramic-supported processes.

Ready to elevate your lab’s capabilities? Contact KINTEK today to discuss your custom furnace solution!

Visual Guide

References

- Chunxia Yang, Rong Xiang. Janus MoSSe Nanotubes on 1D SWCNT‐BNNT van der Waals Heterostructure. DOI: 10.1002/smll.202412454

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What precautions should be taken when handling MoSi2 heating elements? Ensure Longevity and Safety in High-Temp Applications

- What are the key features of GC Type Silicon Carbide Heating Elements? Discover Their High-Temperature Resilience

- What is the role of a temperature controller in the closed-loop regulation system? Master Precision Heat Control

- How do thick film heating elements differ from other types? Discover Speed, Precision, and Efficiency

- What is the monitoring function of armored thermocouples in geopolymer fire resistance experiments?

- What is the most efficient heating element? Find the Most Effective Solution for Your Needs

- Why is the placement of precision thermocouples at the base of the quartz crucible critical in InSe crystal growth?

- What makes MoSi2 heating elements easy to replace? Achieve Minimal Downtime with Hot-Swap Capability