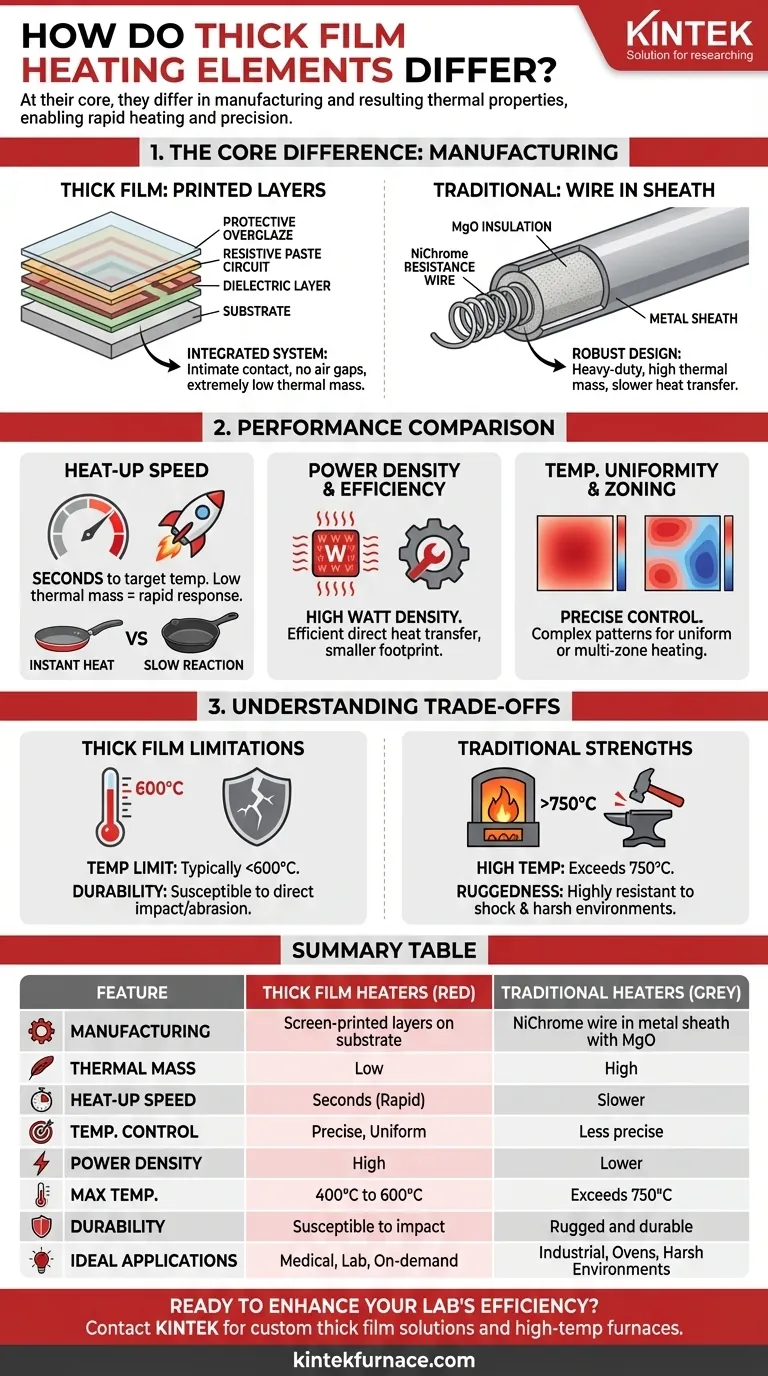

At their core, thick film heating elements differ from traditional heaters in their manufacturing process and resulting thermal properties. Instead of using a conventional wire coil, thick film heaters are created by screen-printing layers of specialized resistive and dielectric pastes onto a substrate, which are then fired at high temperatures. This process results in an element with extremely low thermal mass, enabling rapid heating and precise temperature control that older technologies cannot match.

The fundamental distinction is one of design philosophy. Traditional heaters are built for ruggedness and high-temperature power, while thick film heaters are engineered for speed, precision, and a compact, integrated form factor.

The Core Difference: Manufacturing and Design

The way a heating element is constructed dictates its performance characteristics. Understanding the manufacturing process is key to grasping the fundamental differences between these technologies.

Thick Film: Printed Layers on a Substrate

A thick film heater is not a discrete component but an integrated system. The process involves printing a resistive circuit directly onto a flat or tubular substrate, typically made of ceramic, stainless steel, or aluminum.

This layered construction means the heating element is in intimate contact with the surface it's heating. There is no air gap or bulky insulation to slow down heat transfer, which is the source of its primary advantages.

Conventional Heaters: Resistor Wires in Sheaths

Most traditional heaters, like tubular or cartridge elements, rely on a nickel-chromium (NiChrome) resistance wire. This wire is coiled and suspended within a metal tube, insulated from the outer sheath by a compacted ceramic powder like magnesium oxide (MgO).

This robust, heavy-duty design is excellent for durability but inherently creates high thermal mass. The heat must first warm the wire, then conduct through the MgO powder, and finally heat the outer sheath before it can be transferred to your target.

How This Impacts Performance

The contrast in construction leads to significant, measurable differences in how these heaters perform in a real-world application.

Heat-Up Speed and Response Time

This is the most significant advantage of thick film technology. Due to their low thermal mass, thick film heaters can reach target temperatures in seconds.

Think of it like the difference between heating a thin, lightweight frying pan versus a heavy, cast-iron skillet. The lightweight pan (thick film) heats up and cools down almost instantly, while the cast iron skillet (tubular heater) takes much longer to react to changes in power.

Power Density and Efficiency

Power density refers to the amount of power (watts) that can be delivered per unit of surface area. Thick film heaters excel here, often achieving very high watt densities.

Because the resistive circuit is printed directly on the substrate, heat transfer is extremely efficient. Nearly all the energy generated is transferred directly to the surface, minimizing wasted energy and allowing for more power in a smaller footprint.

Temperature Uniformity and Zoning

The screen-printing process allows for the creation of incredibly complex and customized circuit patterns. This means heat can be distributed unevenly on purpose to achieve a perfectly uniform temperature across a non-uniform part.

Furthermore, multiple, independent heating circuits can be printed on a single substrate. This allows for sophisticated zone heating, where different areas of a component can be controlled to different temperatures simultaneously.

Understanding the Trade-offs

No technology is superior in all situations. The unique properties of thick film heaters come with specific limitations that make other technologies a better fit for certain applications.

Temperature Limitations

While excellent for moderate temperatures, thick film heaters are typically limited by the materials used in their construction, with maximum operating temperatures often falling in the 400°C to 600°C range. For extreme heat applications exceeding 750°C, robust tubular or ceramic heaters remain the standard.

Durability and Mechanical Strength

The rugged, overbuilt nature of a tubular heater makes it highly resistant to physical shock, vibration, and harsh industrial environments. A thick film element, being a series of printed layers on a substrate, is inherently more susceptible to damage from direct impact or abrasion.

Application Suitability

Thick film technology is ideal for heating flat or tubular surfaces and fluids that flow over them. It is less suitable for immersion in corrosive liquids or for insertion into drilled holes (a primary use for cartridge heaters) unless integrated into a specially designed assembly.

Making the Right Choice for Your Application

Selecting the correct heating element requires aligning the technology's strengths with your primary design goal.

- If your primary focus is speed and precision: Thick film is the definitive choice for applications needing rapid thermal response, such as medical diagnostics, analytical instruments, and on-demand water heaters.

- If your primary focus is ruggedness and high temperatures: Traditional tubular or cartridge heaters are better suited for heavy industrial machinery, ovens, and process heating in harsh environments.

- If your primary focus is integrating heat into a complex assembly: Thick film's ability to be printed directly onto a component can simplify product design and reduce parts counts.

- If your primary focus is high-volume production: The automated screen-printing process makes thick film highly cost-effective at scale, despite potentially higher initial tooling costs.

By understanding these core differences, you can confidently select the heating technology that delivers the precise performance your application demands.

Summary Table:

| Feature | Thick Film Heaters | Traditional Heaters |

|---|---|---|

| Manufacturing | Screen-printed layers on substrate | NiChrome wire in metal sheath with MgO insulation |

| Thermal Mass | Low | High |

| Heat-Up Speed | Seconds | Slower |

| Temperature Control | Precise | Less precise |

| Power Density | High | Lower |

| Max Temperature | 400°C to 600°C | Exceeds 750°C |

| Durability | Susceptible to impact | Rugged and durable |

| Ideal Applications | Medical devices, analytical instruments, on-demand heating | Industrial ovens, harsh environments, high-temp processes |

Ready to enhance your lab's heating efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including custom thick film heaters. With our strong R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Contact us today to discuss how our deep customization capabilities can optimize your experiments and processes!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure