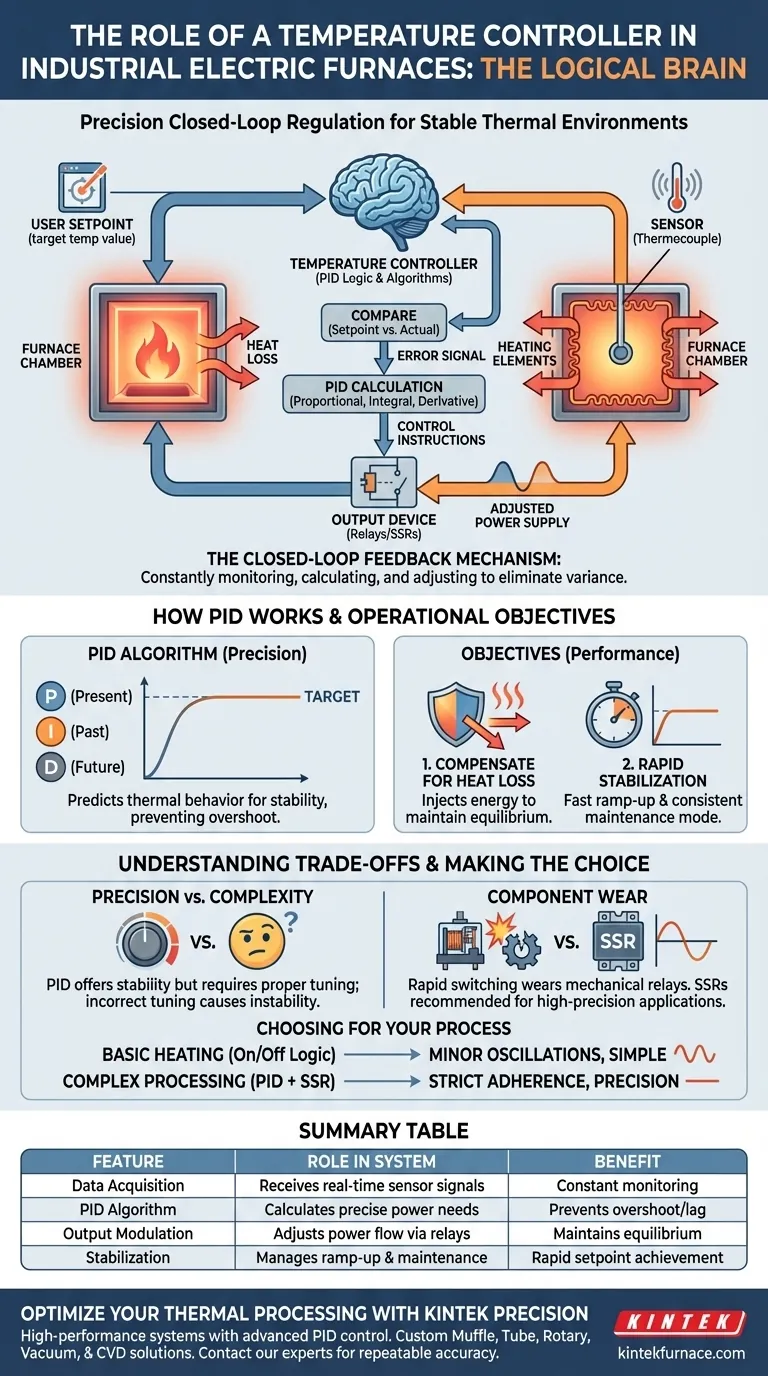

The temperature controller functions as the logical brain of an industrial electric furnace's closed-loop regulation system. Its primary role is to continuously compare the user's defined target temperature against the actual internal heat measured by sensors. Based on the variance between these two values—known as the error signal—it calculates precise instructions to modulate the power supplied to the heating elements, ensuring the furnace maintains a stable thermal environment.

By processing error signals through advanced algorithms like PID, the controller transforms raw temperature data into actionable power adjustments, actively compensating for heat loss to eliminate fluctuations and lock in precise setpoints.

The Closed-Loop Feedback Mechanism

Receiving the Error Signal

The control loop begins with data acquisition. The controller monitors the current internal temperature via sensors, such as thermocouples.

It constantly compares this real-time measurement against the reference temperature (the setpoint) you have programmed. The difference between these two values is identified as the error signal, which triggers the regulation process.

Algorithmic Calculation (PID)

To achieve high precision, modern controllers do not simply switch heaters on and off. They utilize Proportional, Integral, and Derivative (PID) algorithms.

This logic allows the controller to predict thermal behavior. It calculates exactly how much power is required not just to reach the setpoint, but to arrive there without overshooting or lagging.

Modulating Output Power

Once the calculation is complete, the controller issues control instructions.

It sends signals to output devices, such as electromagnetic or solid-state relays. These relays adjust the electrical current flowing to the heating elements, effectively throttling the heat output up or down based on the controller's demands.

Operational Objectives

Compensating for Heat Loss

Every furnace experiences natural energy loss to its surroundings. The controller’s role is to dynamically offset this loss.

By monitoring the rate of temperature change, it injects precise amounts of energy to maintain equilibrium, ensuring the chamber does not cool down during operation.

Rapid Stabilization

In industrial processes like pyrolysis, time is critical. The controller ensures the furnace environment stabilizes rapidly at the target value.

It manages the initial ramp-up phase to reach the target temperature quickly, then immediately shifts to a maintenance mode to keep the heat curve flat and consistent.

Understanding the Trade-offs

Precision vs. Complexity

While PID controllers offer superior stability, they introduce complexity in tuning. A PID controller that is not properly tuned to the furnace's thermal mass can cause system instability, leading to erratic temperature swings.

Component Wear

High-precision control often involves rapid switching of power to maintain a specific temperature.

This constant modulation can increase wear on mechanical relays. For high-precision applications involving frequent cycling, solid-state relays (SSRs) are often required to handle the load without mechanical failure.

Making the Right Choice for Your Process

The effectiveness of your furnace regulation depends on matching the controller's capabilities to your specific application requirements.

- If your primary focus is basic, non-critical heating: A simple on/off control logic may be sufficient, accepting that there will be minor temperature oscillations around the setpoint.

- If your primary focus is complex material processing: You must rely on a fully tuned PID controller with solid-state relays to eliminate fluctuations and ensure strict adherence to thermodynamic parameters.

The controller is the defining component that turns a simple heater into a precision instrument capable of repeatable industrial results.

Summary Table:

| Feature | Role in Closed-Loop System | Benefit to Operation |

|---|---|---|

| Data Acquisition | Receives error signals from thermocouples | Constant real-time monitoring |

| PID Algorithm | Calculates precise power requirements | Prevents overshoot and thermal lagging |

| Output Modulation | Controls relays to adjust power flow | Maintains equilibrium against heat loss |

| Stabilization | Manages ramp-up and maintenance phases | Ensures rapid reaching of setpoints |

Optimize Your Thermal Processing with KINTEK Precision

Is your production suffering from temperature fluctuations? As a leader in laboratory and industrial heating solutions, KINTEK provides high-performance systems integrated with advanced PID control logic. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thermodynamic requirements.

Don't let heat loss compromise your results. Contact our experts today to discover how our precision-engineered furnaces can bring repeatable accuracy to your lab or facility.

Visual Guide

References

- Serdar Ekinci, Євген Зайцев. Efficient control strategy for electric furnace temperature regulation using quadratic interpolation optimization. DOI: 10.1038/s41598-024-84085-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What types of industrial applications are MoSi2 heating elements best suited for? Maximize High-Temp Stability

- What are ceramic heaters and how do they differ from regular panel heaters? Compare for Better Heating Choices

- What customization options are available for graphite heating elements? Achieve Perfect Thermal Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are high-precision stainless steel thermocouples and handheld readers required to characterize the temperature field of a tube furnace?

- What makes Iron-Chrome-Aluminium alloys suitable for high-temperature applications? Discover the Power of Self-Healing Alumina Layers

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- How does a graphite heater work? Achieving Extreme Temperatures Beyond 2000°C