At its core, the customization of graphite heating elements is virtually limitless. Because they are produced by machining solid blocks of high-purity graphite, they can be fabricated into almost any conceivable size or shape. This manufacturing process allows for designs ranging from massive elements for large industrial furnaces to smaller, more conventional components tailored to specific thermal tasks.

The extensive customization of graphite heating elements stems directly from the material's excellent machinability. This allows for nearly any size or shape to be created, enabling precise thermal performance tailored to the unique geometric and operational requirements of high-temperature vacuum furnaces.

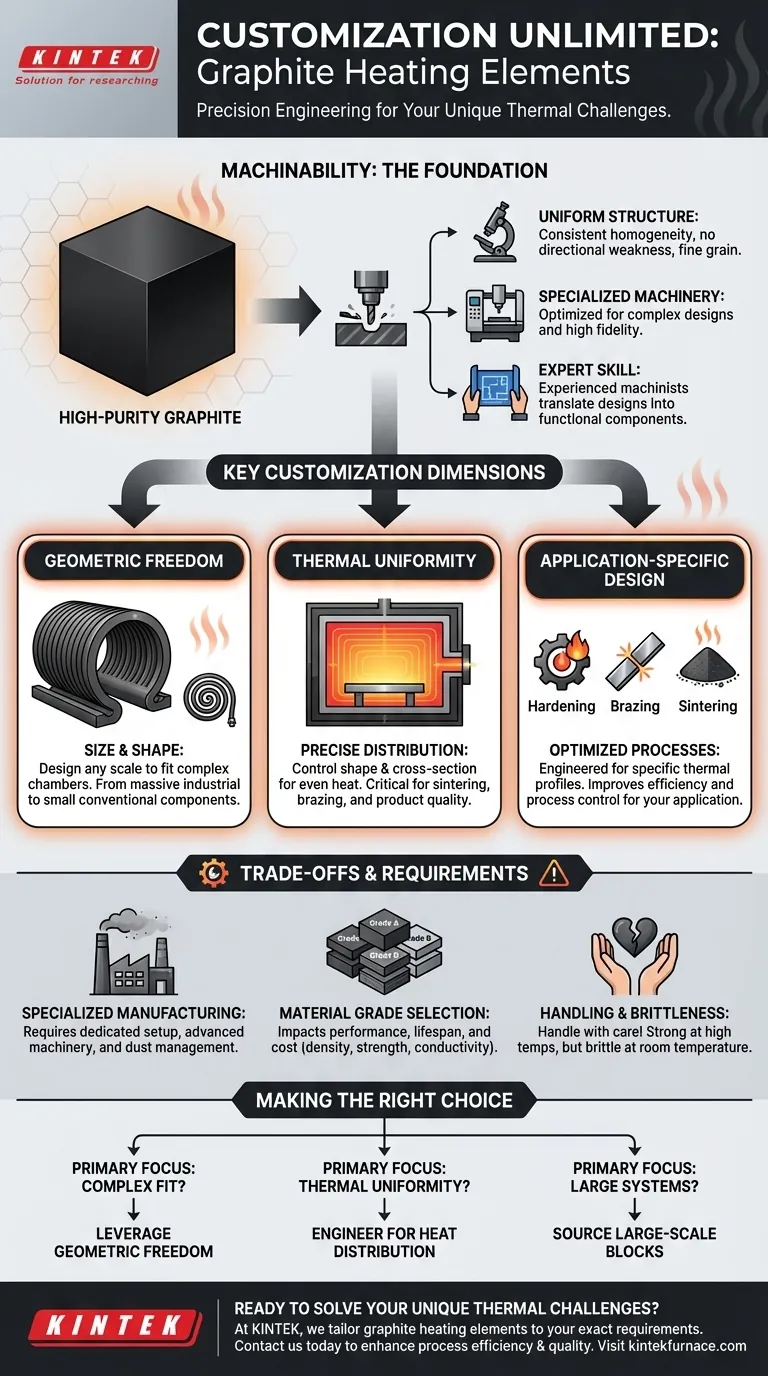

The Foundation of Customization: Machinability

The ability to shape graphite with precision is the key to its versatility as a heating element. This is not an accident of the material, but a result of its fundamental properties and the specialized processes used to work it.

Why Graphite is Easily Machined

The isostatic graphite grades typically used for heating elements are exceptionally uniform. Their consistent homogeneity and fine grain structure mean the material has no inherent directional weakness, allowing for smooth, predictable machining that results in a uniform final component.

From Raw Block to Final Element

The process begins with large, solid blocks of graphite. These blocks serve as the raw material from which the final heating element is carved. Using machines optimized specifically for graphite, skilled technicians can execute complex designs with high fidelity.

The Critical Role of Expertise

Achieving a high-quality, custom element is not just about the material. It requires skilled machinists with deep experience in the nuances of working with graphite. Their expertise is essential to translate a design into a functional, reliable heating component.

Key Customization Dimensions

The freedom to machine graphite allows designers to optimize elements across several critical performance dimensions, moving beyond simple "off-the-shelf" solutions.

Geometric Freedom (Size and Shape)

This is the most direct form of customization. Elements can be made exceptionally large for massive industrial applications or shaped into intricate patterns to fit within complex furnace chambers. This ensures that the heat source is perfectly integrated with the equipment it serves.

Designing for Thermal Uniformity

By precisely controlling the element's shape and cross-section, engineers can dictate how heat is generated and distributed. This capability is critical for processes like sintering metals or brazing copper, where uniform temperature across the workload is non-negotiable for product quality.

Application-Specific Design

Customization allows elements to be designed for specific industrial processes. Whether for metal hardening, brazing, or creating sintered parts, the element can be engineered to deliver the exact thermal profile required by the application, improving efficiency and process control.

Understanding the Trade-offs and Requirements

While graphite is highly customizable, this flexibility comes with a set of practical considerations and requirements that must be managed.

Specialized Manufacturing is Non-Negotiable

You cannot produce high-quality graphite elements with general-purpose machine tools. The process requires a dedicated setup with optimized machinery and advanced dust collection to manage graphite particles. This means customization is dependent on suppliers with this specific capability.

The Importance of Material Grade

The reference to "a variety of graphite blocks" is key. Different grades of graphite have different properties, such as density, strength, and thermal conductivity. The choice of raw material is a critical customization step that impacts the element's performance, lifespan, and cost.

Handling and Brittleness

While extremely strong at high temperatures, graphite can be brittle at room temperature. Custom-machined elements, especially those with intricate features or thin sections, must be handled, installed, and supported with care to prevent mechanical fracture before they ever reach operating temperature.

Making the Right Choice for Your Design

Your specific goal will determine how you leverage the customization options available for graphite heating elements.

- If your primary focus is fitting a complex furnace geometry: Leverage graphite's machinability to design an element that precisely matches your chamber's unique shape, maximizing usable space.

- If your primary focus is achieving maximum thermal uniformity: Work with an experienced supplier to engineer an element whose geometry is optimized for the most even heat distribution possible.

- If your primary focus is building a very large high-temperature system: Confirm that your supplier can source and machine the large-scale graphite blocks required to produce elements of the necessary size.

Ultimately, the design flexibility of graphite allows you to solve thermal challenges through precise engineering rather than compromise.

Summary Table:

| Customization Dimension | Key Benefit |

|---|---|

| Geometric Freedom | Design any size or shape to fit complex furnace chambers. |

| Thermal Uniformity | Engineer elements for precise, even heat distribution. |

| Application-Specific Design | Optimize for processes like sintering, brazing, or hardening. |

Ready to solve your unique thermal challenges?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our deep customization capabilities allow us to precisely tailor graphite heating elements to your exact geometric and thermal requirements, ensuring optimal performance for your specific application.

Whether you need a standard component or a fully custom design, our expertise in materials like high-purity graphite and our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—ensures you get a reliable, high-performance solution.

Contact us today to discuss your project and discover how our custom heating elements can enhance your process efficiency and product quality.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity