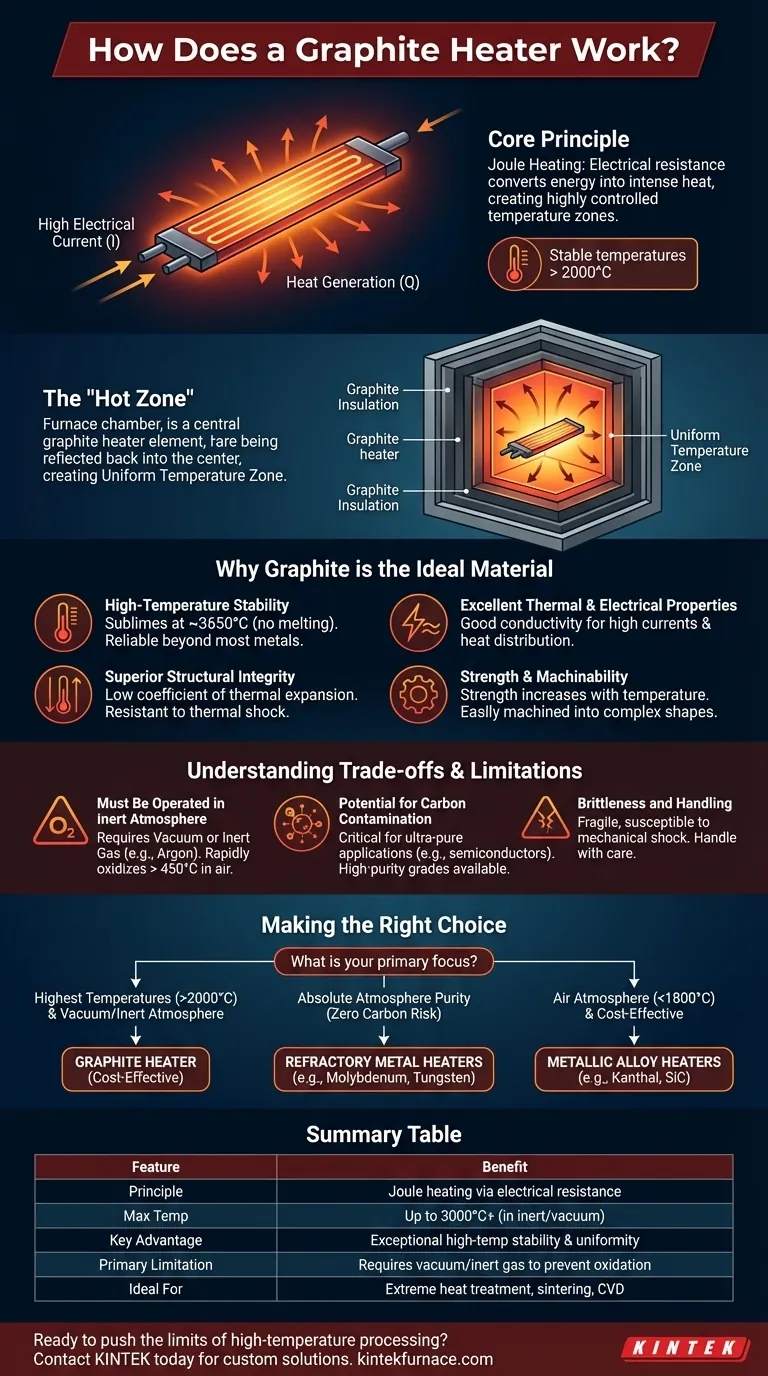

At its core, a graphite heater works by passing a high electrical current through resistive graphite elements. These specially shaped elements, often rods or plates, heat up due to their internal electrical resistance. This process, known as Joule heating, allows for the creation of intensely hot and highly controlled temperature zones, particularly within vacuum or inert gas furnaces.

Achieving stable, uniform temperatures above 2000°C is an extreme engineering challenge. Graphite heaters solve this by leveraging graphite's unique combination of electrical conductivity and an exceptionally high sublimation point, making it one of the few materials suitable for the most demanding high-temperature applications.

The Fundamental Principle: Resistive Heating

The operation of a graphite heater is governed by a simple and elegant physical law. Understanding this principle is key to appreciating its effectiveness.

How Current Generates Heat

When an electrical current flows through any material with resistance, electrical energy is converted into thermal energy, or heat. This is described by Joule's first law.

The graphite elements in the heater are designed to have a specific electrical resistance. By precisely controlling the voltage and current supplied, you can precisely control the amount of heat generated.

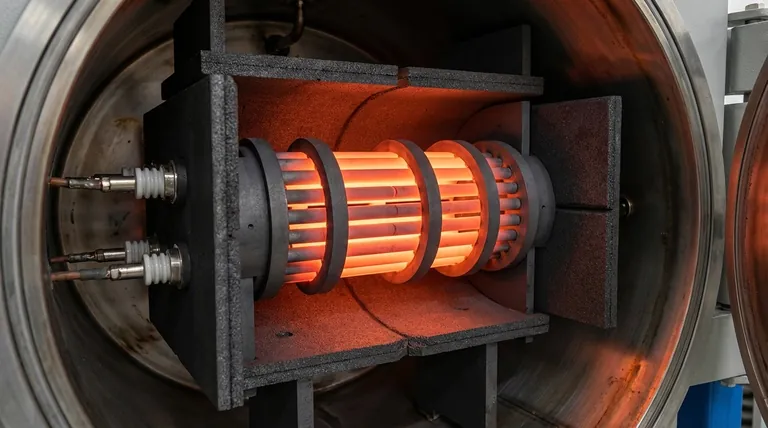

The Role of the "Hot Zone"

These heating elements are typically arranged within a chamber to form a "hot zone." This zone is surrounded by graphite insulation, which reflects radiant heat back into the center, minimizing energy loss and ensuring the temperature is highly uniform throughout the target area.

Why Graphite is the Ideal Material

While many materials can be used for resistive heating, graphite possesses a combination of properties that make it uniquely suited for extreme temperature environments.

Exceptionally High-Temperature Stability

This is graphite's most critical advantage. Unlike metals that melt, graphite sublimes (turns directly from a solid to a gas) at approximately 3650°C (6600°F) at atmospheric pressure. This allows it to operate reliably at temperatures far beyond the melting point of most metals.

Excellent Thermal and Electrical Properties

Graphite is a good electrical conductor, allowing high currents to pass through it, but it has enough resistance to generate substantial heat. It also has high thermal conductivity, which helps distribute heat evenly across the element, preventing hot spots and promoting a uniform furnace temperature.

Superior Structural Integrity

Graphite has a very low coefficient of thermal expansion. This means it does not significantly expand or contract when heated and cooled. This property makes it highly resistant to thermal shock, reducing the risk of cracking or warping during rapid temperature cycles.

Strength and Machinability

Graphite's strength actually increases with temperature up to about 2500°C, a rare and valuable property. It is also relatively easy to machine, allowing for the creation of complex and precise heating element shapes, such as rods, tubes, cylinders, and serpentine plates.

Understanding the Trade-offs and Limitations

No technology is without its drawbacks. An objective assessment requires understanding the operational constraints of graphite heaters.

The Critical Need for an Inert Atmosphere

Graphite's primary weakness is its reaction with oxygen. Above approximately 450°C (842°F), graphite will rapidly oxidize, or burn away.

Therefore, graphite heaters must be operated in a vacuum or be backfilled with an inert gas like argon or nitrogen. They cannot be used in an open-air environment at high temperatures.

Potential for Carbon Contamination

In certain ultra-pure applications, such as semiconductor processing or medical implant manufacturing, the graphite itself can be a source of carbon contamination. While high-purity graphite grades exist, this is a critical consideration where any foreign particle is unacceptable.

Brittleness and Handling

Unlike ductile metals, graphite is a brittle material. The heating elements and insulation can be fragile and must be handled with care to avoid chipping or cracking due to mechanical shock.

Making the Right Choice for Your Application

Selecting the correct heating technology depends entirely on your operational goals.

- If your primary focus is achieving the highest possible temperatures (>2000°C): Graphite is often the superior and most cost-effective choice, provided you can operate in a vacuum or inert environment.

- If your primary focus is absolute atmosphere purity with zero carbon risk: You should consider refractory metal heaters (like molybdenum, tantalum, or tungsten) as a necessary alternative.

- If your primary focus is cost-effective heating in an air atmosphere below 1800°C: Metallic alloy heaters (such as those made from Kanthal or silicon carbide) are the more practical and appropriate solution.

Understanding these core principles and trade-offs empowers you to select the right heating technology for your specific high-temperature objective.

Summary Table:

| Feature | Benefit |

|---|---|

| Principle | Joule heating via electrical resistance |

| Max Temperature | Up to 3000°C+ (in inert/vacuum atmosphere) |

| Key Advantage | Exceptional high-temperature stability & uniformity |

| Primary Limitation | Requires vacuum or inert gas to prevent oxidation |

| Ideal For | Extreme heat treatment, sintering, CVD processes |

Ready to push the limits of high-temperature processing?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our deep customization capabilities allow us to precisely tailor graphite heater systems—including our Muffle, Tube, Vacuum & Atmosphere, and CVD/PECVD Furnaces—to your unique experimental and production requirements.

Contact our experts today to discuss how a custom high-temperature furnace can solve your most challenging thermal processing needs.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency