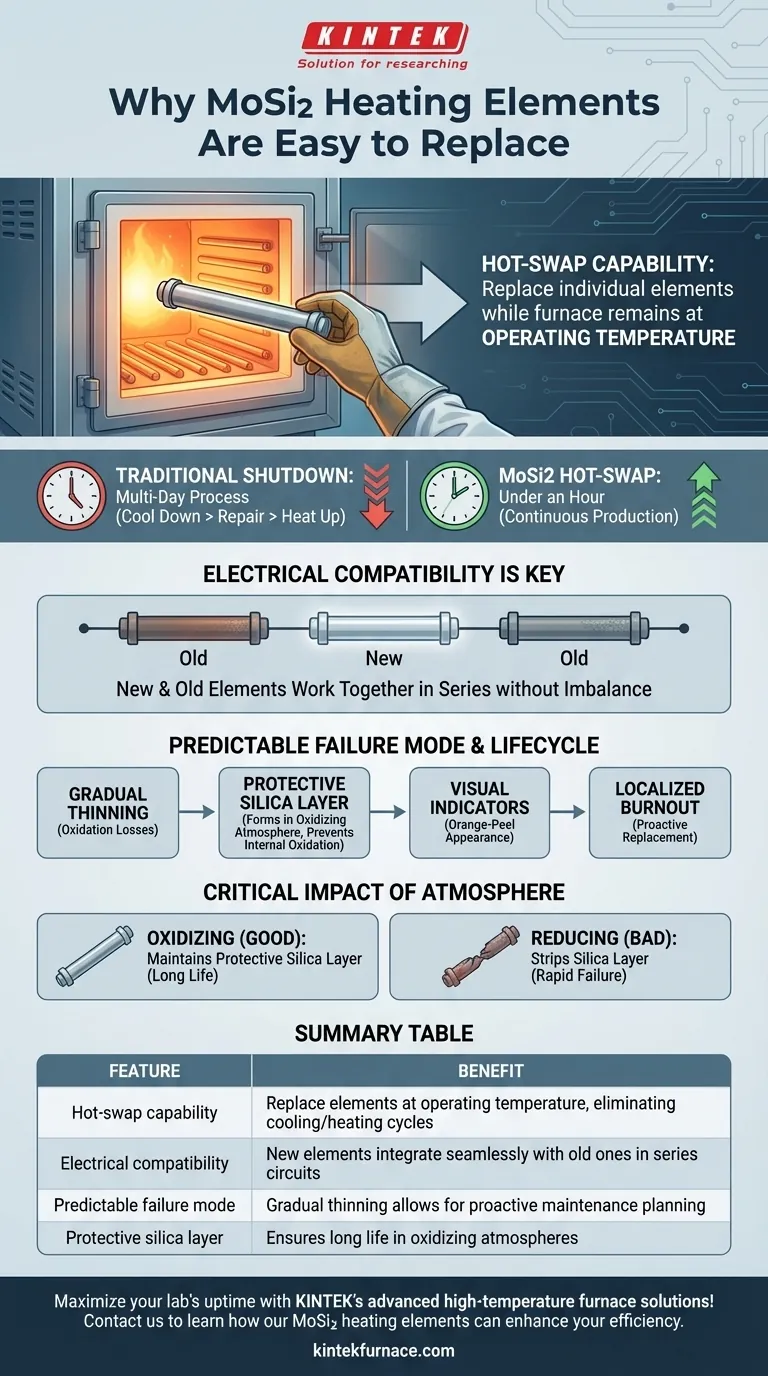

The defining feature that makes Molybdenum Disilicide (MoSi2) heating elements easy to replace is the ability to swap them out individually while the furnace remains at operating temperature. This unique characteristic allows for continuous production and drastically minimizes the costly downtime associated with cooling and reheating a high-temperature furnace.

The ease of replacing MoSi2 elements is a critical design advantage rooted in their material stability. Because new and old elements are electrically compatible, a failed unit can be replaced individually without disrupting the entire heating system or requiring a full furnace shutdown.

The Core Principle: Minimizing Operational Downtime

The primary benefit of MoSi2 element design revolves around maintaining continuous operation. In high-temperature industrial processes, shutting down a furnace is a significant event that costs both time and money.

Eliminating Costly Shutdowns

Traditional furnace maintenance often requires a full cycle of cooling down, performing the repair, and slowly heating back up to temperature.

MoSi2 elements can be replaced while the furnace is hot, turning a multi-day process into a task that can often be completed in under an hour, ensuring production continuity.

Electrical Compatibility is Key

A critical factor enabling this convenience is the excellent compatibility between old and new elements.

Unlike some heating materials that change electrical resistance significantly as they age, MoSi2 elements remain relatively stable. This means a new element can be wired into a series circuit with older, existing elements without creating imbalances in power distribution or performance.

Designed for Series Circuits

MoSi2 elements are typically wired in series circuits. When one element fails, it creates an open circuit, and the entire zone stops heating.

The ability to quickly identify and replace the single failed component is essential for restoring furnace operation promptly.

Understanding the Lifecycle and Failure Mode

The replacement process is also informed by how these elements age and eventually fail. Their failure is predictable, allowing for proactive rather than reactive maintenance.

Failure Through Gradual Thinning

MoSi2 elements do not typically fail suddenly. Instead, they fail due to gradual thinning caused by oxidation losses over a long service life.

As the element thins, its power density increases until a localized spot overheats and burns out. This predictable wear allows operators to anticipate replacements.

The Protective Silica Layer

In their ideal operating condition—an oxidizing atmosphere—the elements form a protective outer layer of silica (glass). This layer prevents internal oxidation and is the key to their long life at extreme temperatures.

Visual Indicators of Aging

At very high temperatures, grain growth can contribute to thinning and may give the element's surface an "orange-peel" appearance. This can serve as a visual cue that the element is nearing the end of its operational life.

Understanding the Trade-offs and Best Practices

While robust, MoSi2 elements have specific operational requirements that must be respected to maximize their lifespan and performance.

The Critical Impact of Atmosphere

The lifespan of MoSi2 elements is heavily dependent on the furnace environment. They are designed for continuous work in an oxygen-rich (oxidizing) atmosphere.

Switching to a reducing atmosphere (like hydrogen or cracked ammonia) is highly detrimental. It strips away the protective silica layer, leaving the element vulnerable to rapid internal oxidation and premature failure.

Vulnerability to Contamination

These elements are susceptible to damage from certain contaminants. Technicians must be diligent to prevent issues.

For example, failing to properly dry colored or painted zirconia before heating can release vapors that attack the elements. Proper furnace maintenance and clean operating procedures are paramount.

Mechanical Integrity

Modern MoSi2 elements benefit from a special joint molding process that gives them strong impact resistance. However, like many ceramic-based materials, they can be brittle at room temperature and must be handled with care during installation.

Applying This to Your Operations

To leverage the full benefit of MoSi2 elements, align your maintenance strategy with your primary operational goal.

- If your primary focus is maximizing uptime: Train technicians on safe, hot replacement procedures. This capability is the single greatest advantage for avoiding production halts.

- If your primary focus is extending element lifespan: Maintain a consistent oxidizing atmosphere. Avoid cycling between oxidizing and reducing environments to preserve the element's protective silica layer.

- If your primary focus is ensuring process reliability: Implement strict protocols to prevent contamination. Ensure all materials placed in the furnace are clean and properly prepared to avoid chemical attacks on the elements.

By understanding both the unique replacement advantages and the critical operating parameters of MoSi2 elements, you can ensure maximum furnace efficiency and productivity.

Summary Table:

| Feature | Benefit |

|---|---|

| Hot-swap capability | Replace elements at operating temperature, eliminating cooling/heating cycles |

| Electrical compatibility | New elements integrate seamlessly with old ones in series circuits |

| Predictable failure mode | Gradual thinning allows for proactive maintenance planning |

| Protective silica layer | Ensures long life in oxidizing atmospheres |

Maximize your lab's uptime with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to learn how our MoSi2 heating elements and tailored support can enhance your operational efficiency and reduce downtime!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism