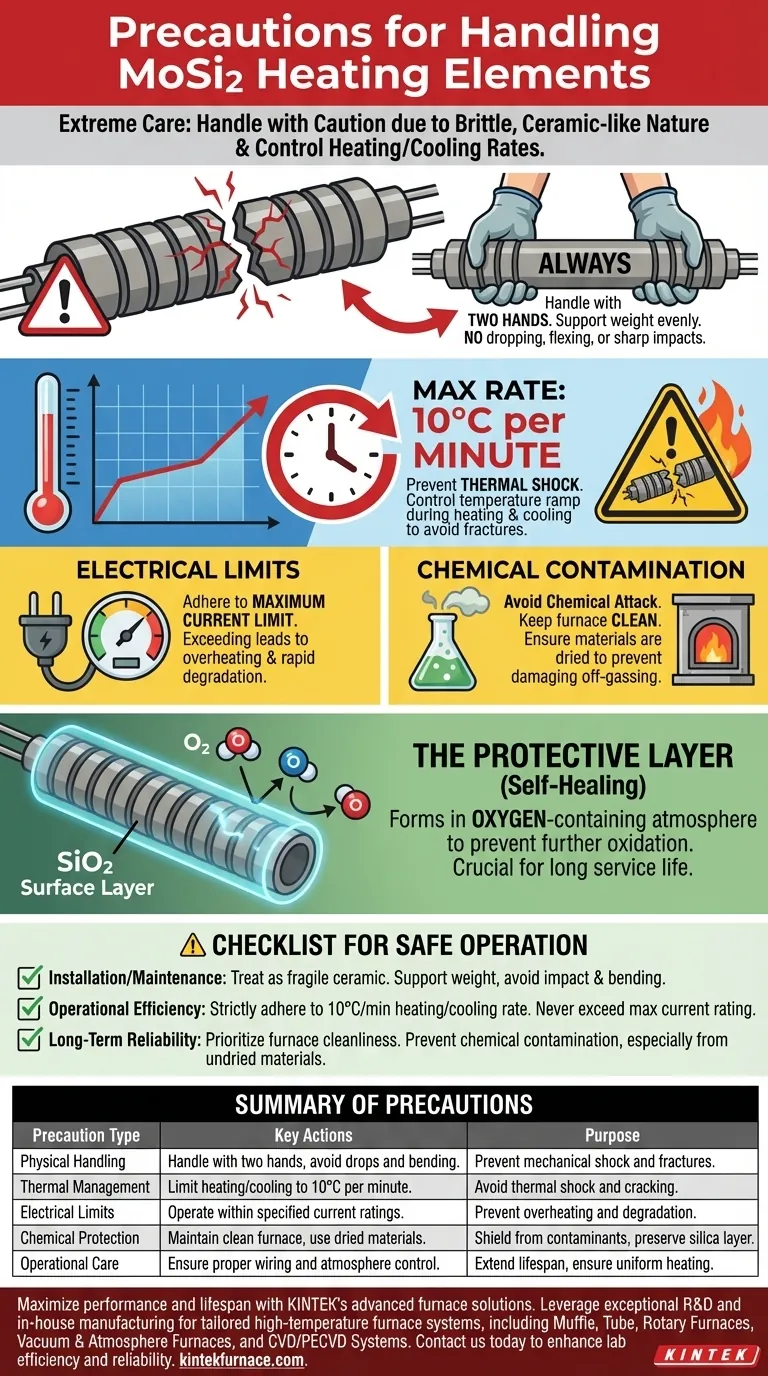

When handling MoSi2 heating elements, the most critical precautions are to handle them with extreme care due to their brittle, ceramic-like nature and to control their heating and cooling rates. Rapid temperature changes can cause thermal shock and fracture the element, so a maximum rate of 10°C per minute is strongly advised.

The necessary precautions for MoSi2 elements extend beyond simple physical handling. Their ceramic nature makes them highly susceptible to both mechanical and thermal shock, while their operational integrity depends on maintaining a clean, controlled environment to prevent chemical contamination at high temperatures.

The Core Challenge: Managing Brittleness

Molybdenum disilicide (MoSi2) elements are valued for their extraordinary performance at high temperatures, but this performance comes from their ceramic properties, which make them extremely brittle at room temperature.

Physical Handling Procedures

The elements have a low fracture toughness and bending strength. This means they cannot tolerate being dropped, flexed, or subjected to sharp impacts.

Always handle them with two hands, supporting their weight evenly. During installation, ensure they are not stressed or forced into position.

Preventing Thermal Shock

Thermal shock is the primary cause of non-mechanical failure. When a brittle material is heated or cooled too quickly, different parts of the element expand or contract at different rates, creating internal stress that leads to cracking.

To prevent this, you must adhere to a controlled temperature ramp. The recommended maximum rate is 10°C per minute. This ensures the element heats and cools uniformly, minimizing internal stress.

Operational Precautions for Maximum Lifespan

Beyond initial handling, long-term reliability depends on correct operational procedures that respect the element's electrical and chemical properties.

Adhering to Electrical Limits

MoSi2 elements convert electrical energy into heat. Each element or furnace system has a maximum current limit.

Exceeding this limit will cause the element to overheat beyond its design specifications, potentially leading to rapid degradation or immediate failure. Always operate within the manufacturer's specified electrical parameters.

Avoiding Chemical Contamination

These elements are highly susceptible to chemical attack at high temperatures. This is a common and often overlooked cause of premature failure.

Contaminants from materials inside the furnace, such as binders or colorants in undried zirconia, can react with the element's protective surface. Ensure all materials placed in the furnace are properly prepared and dried according to specifications to prevent off-gassing that could damage the elements.

Understanding the Protective Layer

MoSi2 elements have a unique "self-healing" property. In an oxygen-containing atmosphere, they form a thin, protective layer of pure silica (SiO2) on their surface.

This layer prevents the underlying MoSi2 from oxidizing further. Maintaining a clean, oxygen-rich atmosphere is crucial for this protective layer to form and repair itself, which is key to the element's long service life.

Understanding the Trade-offs

No component is perfect. Understanding the limitations of MoSi2 elements is key to using them effectively.

High-Temperature Performance vs. Low-Temperature Brittleness

The primary trade-off is exceptional high-temperature capability versus extreme brittleness at ambient temperatures. The material properties that allow MoSi2 to operate at temperatures up to 1900°C are the same ones that make it fragile during installation and maintenance.

Longevity vs. Contamination Sensitivity

While MoSi2 elements offer a very long operational lifespan under ideal conditions, this longevity is highly dependent on furnace hygiene. Their performance is robust, but their chemical sensitivity means that poor maintenance practices or the introduction of contaminants can drastically shorten their life.

Wiring and Element Replacement

MoSi2 elements are typically wired in a series circuit. While some modern elements are designed for compatibility between old and new units, it is a critical point to verify. In many series circuits, mixing elements with different resistance values (which occurs as they age) can lead to uneven heating and premature failure of the newer elements.

A Checklist for Safe Operation

Use these guidelines to match your procedures to your primary goal.

- If your primary focus is installation and maintenance: Always treat the elements as fragile ceramic, supporting their weight and avoiding any impact or bending stress.

- If your primary focus is operational efficiency: Strictly adhere to the 10°C per minute heating/cooling rate and never exceed the manufacturer's maximum current rating to prevent thermal shock and electrical damage.

- If your primary focus is long-term reliability: Prioritize furnace cleanliness to prevent chemical contamination, especially from undried materials, to protect the element's vital silica surface.

By understanding and respecting these material properties, you can ensure the long-term reliability and performance of your high-temperature processes.

Summary Table:

| Precaution Type | Key Actions | Purpose |

|---|---|---|

| Physical Handling | Handle with two hands, avoid drops and bending | Prevent mechanical shock and fractures |

| Thermal Management | Limit heating/cooling to 10°C per minute | Avoid thermal shock and cracking |

| Electrical Limits | Operate within specified current ratings | Prevent overheating and degradation |

| Chemical Protection | Maintain clean furnace, use dried materials | Shield from contaminants and preserve silica layer |

| Operational Care | Ensure proper wiring and atmosphere control | Extend lifespan and ensure uniform heating |

Maximize the performance and lifespan of your high-temperature processes with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you avoid common pitfalls like thermal shock and contamination. Contact us today to discuss how our expertise can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs