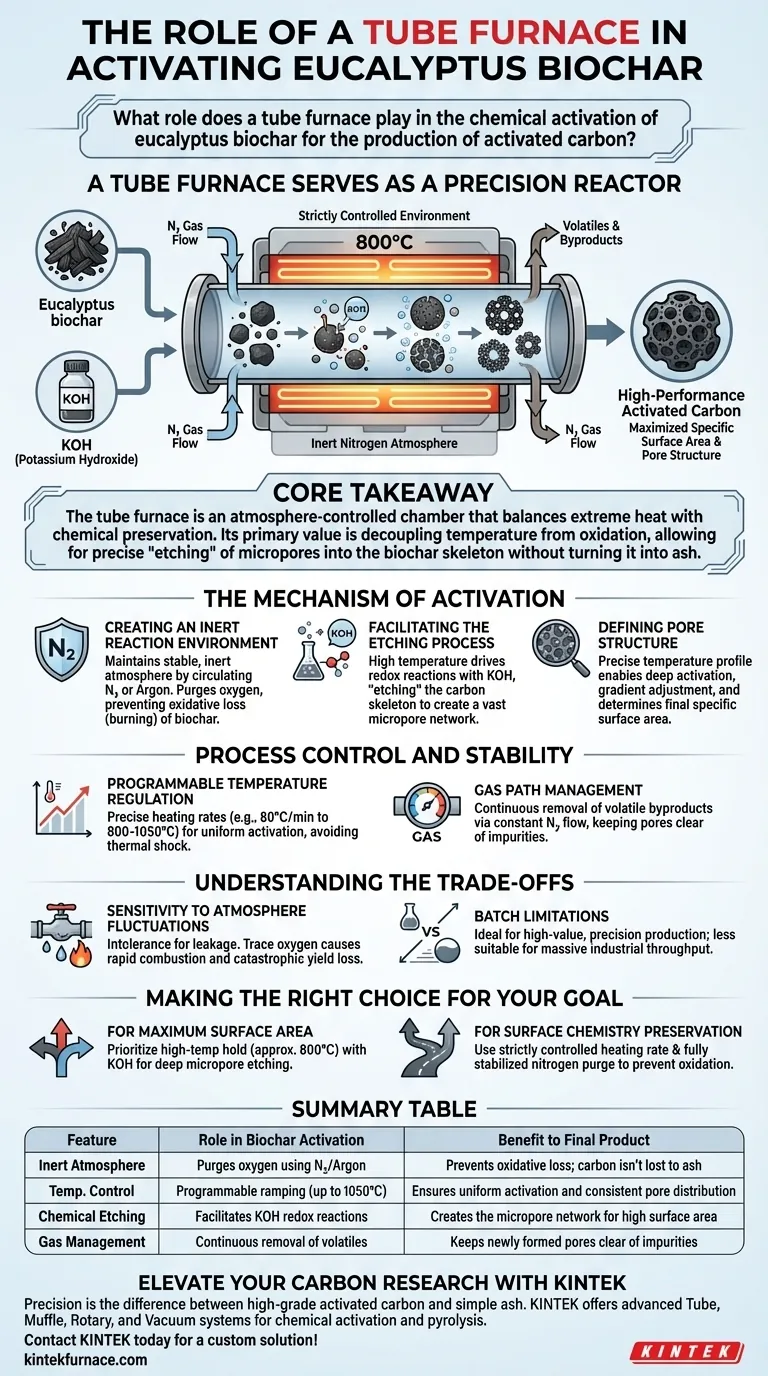

A tube furnace serves as a precision reactor that facilitates the chemical activation of eucalyptus biochar, transforming it into high-performance activated carbon. It provides a strictly controlled environment—typically at 800°C under an inert nitrogen atmosphere—that allows activation agents like potassium hydroxide (KOH) to etch the carbon structure without burning it away. This specific setup is required to maximize the material's specific surface area and develop the pore structure necessary for electrochemical applications.

Core Takeaway: The tube furnace is not merely a heating element; it is an atmosphere-controlled chamber that balances extreme heat with chemical preservation. Its primary value lies in decoupling temperature from oxidation, allowing for the precise "etching" of micropores into the biochar skeleton while preventing the material from turning into ash.

The Mechanism of Activation

Creating an Inert Reaction Environment

The most critical role of the tube furnace is maintaining a stable, inert atmosphere. By circulating nitrogen (N2) or argon, the furnace purges oxygen from the chamber.

This prevents oxidative loss, ensuring the eucalyptus biochar does not burn (oxidize) into carbon dioxide when subjected to extreme heat. Instead of consuming the carbon, the environment forces a targeted chemical reaction between the biochar and the activation agent.

Facilitating the Etching Process

Inside the furnace, the high temperature drives a reaction between the eucalyptus biochar and the chemical agent, specifically potassium hydroxide (KOH).

This process involves redox reactions that "etch" the carbon skeleton. The furnace provides the thermal energy required to drive this etching, creating a vast network of micropores within the material.

Defining Pore Structure

The specific surface area of the final product is directly determined by the furnace's operation.

By strictly controlling the temperature profile, the furnace enables the deep activation of the carbon. This physical restructuring allows for the gradient adjustment of the material's properties, resulting in a high specific surface area essential for superior electrochemical performance.

Process Control and Stability

Programmable Temperature Regulation

Precise heating rates are essential for uniform activation. The tube furnace allows for programmed temperature ramping, such as heating at 80°C/min up to target temperatures of 800°C or even 1050°C.

This precise control ensures the chemical activation occurs at the optimal rate. It prevents thermal shock to the material and ensures the pore size distribution is consistent throughout the batch.

Gas Path Management

A sophisticated gas path system ensures the continuous removal of volatile byproducts generated during pyrolysis.

By delivering a constant flow of nitrogen, the furnace sweeps away impurities that could reclog the newly formed pores. This flow management is a core physical requirement for keeping the activated sites accessible.

Understanding the Trade-offs

Sensitivity to Atmosphere Fluctuations

The primary vulnerability of using a tube furnace is its intolerance for leakage. If the gas seal is compromised or the nitrogen flow is interrupted, oxygen will ingress immediately.

At 800°C, even trace amounts of oxygen will cause rapid combustion of the biochar. This results in a catastrophic loss of yield and destroys the carefully engineered pore structure.

Batch Limitations

While excellent for precision, tube furnaces are typically batch-processing units. They are ideal for high-value, laboratory, or pilot-scale production where quality supersedes quantity.

For massive industrial throughput, the geometric constraints of the tube can be a limiting factor compared to continuous rotary kilns, though the tube furnace offers superior atmosphere control.

Making the Right Choice for Your Goal

To maximize the quality of your eucalyptus-derived activated carbon, align your furnace settings with your specific end-goal:

- If your primary focus is Maximum Surface Area: Prioritize a high-temperature hold (approx. 800°C) with KOH to drive deep micropore etching.

- If your primary focus is Surface Chemistry Preservation: Use a strictly controlled heating rate and ensure the nitrogen purge is fully stabilized before ramping up heat to prevent surface oxidation.

The tube furnace acts as the gatekeeper of quality, determining whether your biochar becomes high-grade activated carbon or simply ash.

Summary Table:

| Feature | Role in Biochar Activation | Benefit to Final Product |

|---|---|---|

| Inert Atmosphere | Purges oxygen using N2/Argon | Prevents oxidative loss; ensures carbon isn't lost to ash |

| Temp. Control | Programmable ramping (up to 1050°C) | Ensures uniform activation and consistent pore distribution |

| Chemical Etching | Facilitates KOH redox reactions | Creates the micropore network for high surface area |

| Gas Management | Continuous removal of volatiles | Keeps newly formed pores clear of impurities |

Elevate Your Carbon Research with KINTEK

Precision is the difference between high-grade activated carbon and simple ash. Backed by expert R&D and manufacturing, KINTEK offers advanced Tube, Muffle, Rotary, and Vacuum systems designed to meet the rigorous demands of chemical activation and pyrolysis.

Whether you need strictly controlled atmosphere management or customizable heating profiles for eucalyptus biochar research, our high-temp lab furnaces provide the stability and durability your project requires.

Ready to optimize your activation process? Contact KINTEK today for a custom solution!

Visual Guide

References

- Bordin Weerasuk, Tanagorn Kwamman. Enhanced dye removal and supercapacitor performance of polyethyleneimine-impregnated activated carbon derived from local eucalyptus biochar. DOI: 10.1039/d4su00421c

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the function of a double-temperature zone tube furnace in CVD synthesis of 2D epsilon-Fe2O3 nanosheets?

- Why are a tube furnace and nitrogen flow required? Master Carbon Microsphere Activation with Precision

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution

- What role does a tube furnace play in the preparation of primitive pomelo peel carbon (PPC)? Master Precision Pyrolysis

- What is the function of a high-temperature tube furnace in Cu(111) transformation? Achieve Atomic Precision

- How is the temperature controlled in a tube furnace? Achieve Precise Thermal Processing for Your Lab

- What is the primary purpose of using a tube furnace during the desizing phase? Optimize Carbon Fiber Surface Purity

- Why is a high-performance tube furnace required for chemical activation? Achieve Precision Pore Control at 700°C