A medium-frequency induction vacuum furnace serves as a high-precision isolation chamber for melting S30403 austenitic stainless steel. It generates heat through electromagnetic induction within a sealed vacuum environment, strictly controlling the melting conditions to protect the alloy from atmospheric contamination and ensure exact chemical composition.

Core Takeaway The primary function of this furnace is to guarantee the chemical purity and accuracy of S30403 stainless steel ingots. By melting in a vacuum, it eliminates the risk of oxidation and gas impurities, enabling the precise retention of volatile trace elements like vanadium.

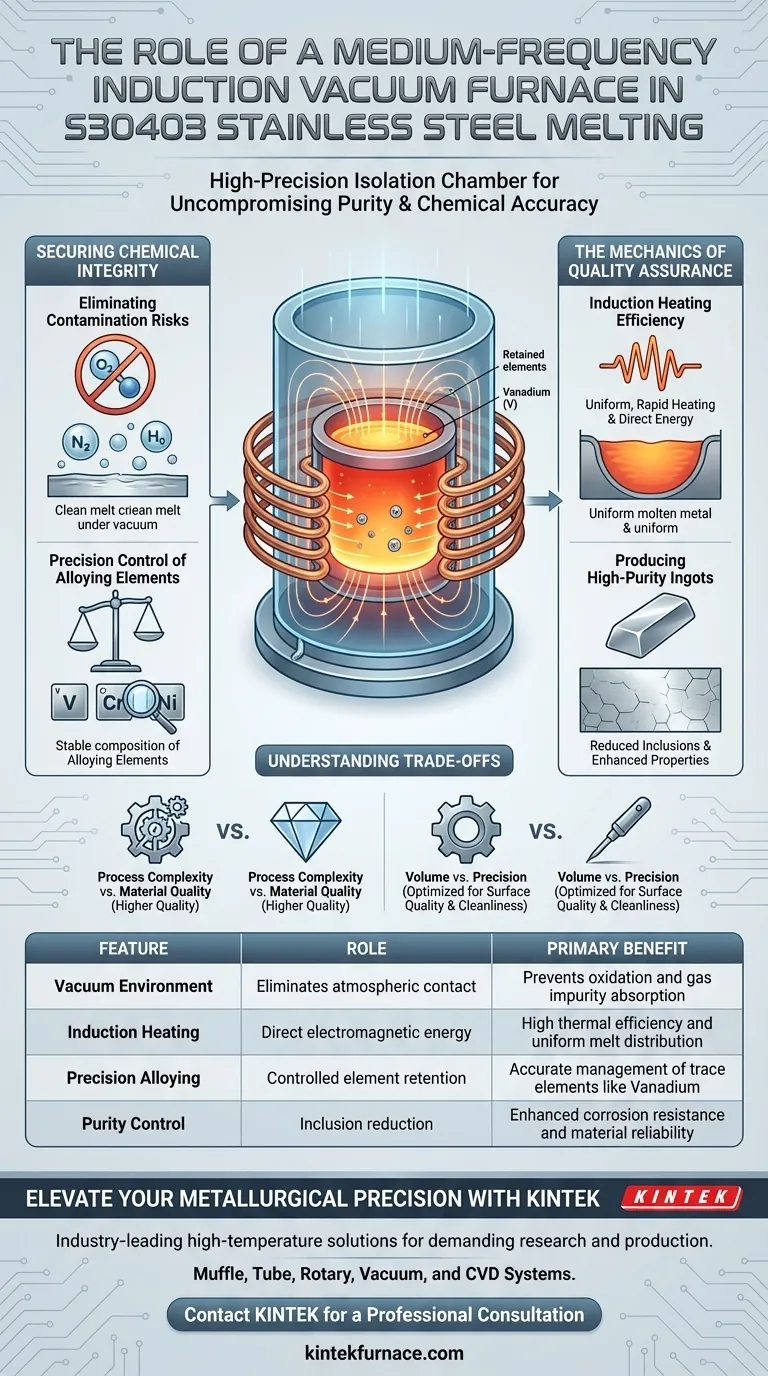

Securing Chemical Integrity

Eliminating Contamination Risks

The most critical role of the furnace is the creation of a controlled vacuum environment. In open-air melting, molten steel interacts with the atmosphere, leading to oxidation and the absorption of unwanted gases.

By removing the air, this furnace effectively prevents oxidation pollution. It ensures that gas impurities are not incorporated into the S30403 matrix, which is vital for maintaining the material's intrinsic properties.

Precision Control of Alloying Elements

S30403 stainless steel often requires the addition of specific trace elements to achieve desired mechanical properties. The primary reference highlights the importance of controlling elements such as vanadium.

In a standard furnace, reactive elements can burn off or oxidize unpredictably. The vacuum induction environment protects these additives, ensuring the final chemical composition matches the theoretical design with high accuracy.

The Mechanics of Quality Assurance

Induction Heating Efficiency

While the vacuum provides the atmosphere, the medium-frequency induction provides the energy. This method uses electromagnetic fields to generate heat directly within the raw material.

This results in a highly uniform melt. It allows for rapid heating while maintaining the strict temperature control necessary to fully melt the steel without overheating specific zones.

Producing High-Purity Ingots

The combination of vacuum protection and induction heating results in experimental stainless steel ingots of exceptional quality.

The process ensures high purity, free from the inclusions and defects that compromise corrosion resistance. This makes the resulting steel reliable for critical testing and high-performance applications.

Understanding the Trade-offs

Process Complexity vs. Material Quality

Utilizing a vacuum induction furnace is inherently more complex than using standard atmospheric furnaces. It requires specialized equipment to maintain the vacuum seal and manage the induction systems.

Volume vs. Precision

These furnaces are typically optimized for quality rather than sheer volume. They are the ideal choice when surface quality and internal cleanliness are paramount, rather than for low-grade, mass-market steel production where slight impurities might be tolerable.

Making the Right Choice for Your Metallurgy

To determine if this melting process aligns with your project goals, consider the following specific requirements:

- If your primary focus is strict chemical composition: Use this furnace to ensure that trace elements like vanadium are retained accurately without oxidation losses.

- If your primary focus is material purity: Rely on the vacuum environment to prevent gas porosity and oxide inclusions that degrade stainless steel performance.

By leveraging a medium-frequency induction vacuum furnace, you transform the melting process from a simple phase change into a precise chemical engineering operation.

Summary Table:

| Feature | Role in S30403 Melting | Primary Benefit |

|---|---|---|

| Vacuum Environment | Eliminates atmospheric contact | Prevents oxidation and gas impurity absorption |

| Induction Heating | Direct electromagnetic energy | High thermal efficiency and uniform melt distribution |

| Precision Alloying | Controlled element retention | Accurate management of trace elements like Vanadium |

| Purity Control | Inclusion reduction | Enhanced corrosion resistance and material reliability |

Elevate Your Metallurgical Precision with KINTEK

Are you looking to achieve uncompromising chemical purity and precise alloy composition for S30403 or other high-performance materials? KINTEK provides industry-leading high-temperature laboratory solutions designed for the most demanding research and production environments.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you require standard configurations or fully customizable furnaces tailored to your unique specifications, our team is ready to support your technical goals.

Transform your melting process into a precise engineering operation today.

Contact KINTEK for a Professional Consultation

Visual Guide

References

- Yaoyao Fiona Zhao, Changrong Li. Effect of V content on high temperature oxidation resistance of S30403 austenitic stainless steel. DOI: 10.1038/s41598-025-17971-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is multiple melting required in a vacuum arc furnace? Achieve Uniform Ni-Mn-Ga Shape Memory Alloys

- What materials are typically processed in vacuum melting furnaces? Unlock High-Purity Material Processing

- What space and cost advantages do induction melting furnaces offer? Boost Efficiency and Save on Expenses

- What are the technical advantages of using a thin-wall with wide slits crucible? Boost Induction Skull Melting Efficiency

- What are the key features of a medium frequency induction furnace? Unlock Faster, Cleaner Metal Processing

- Why is it necessary to reduce the applied secondary voltage during the arc furnace process? Protect Your Furnace and Boost Efficiency

- What is the role of a Vacuum Induction Melting furnace in Fe3Al/Cr3C2 preparation? Purity & Precision for Cladding

- How do induction furnaces enhance productivity in foundries? Boost Melting Speed and Automation for Higher Output