At its core, a medium frequency induction furnace is defined by its exceptional efficiency, rapid heating capabilities, and precise temperature control. These furnaces operate using a medium-frequency power supply, typically between 200 Hz and 2500 Hz, to quickly melt or heat metals with minimal energy waste, resulting in a compact and highly productive system.

The true advantage of a medium frequency furnace is not just a single feature, but how its underlying technology—generating heat directly within the metal itself—creates a process that is fundamentally faster, more controllable, and more efficient than traditional heating methods.

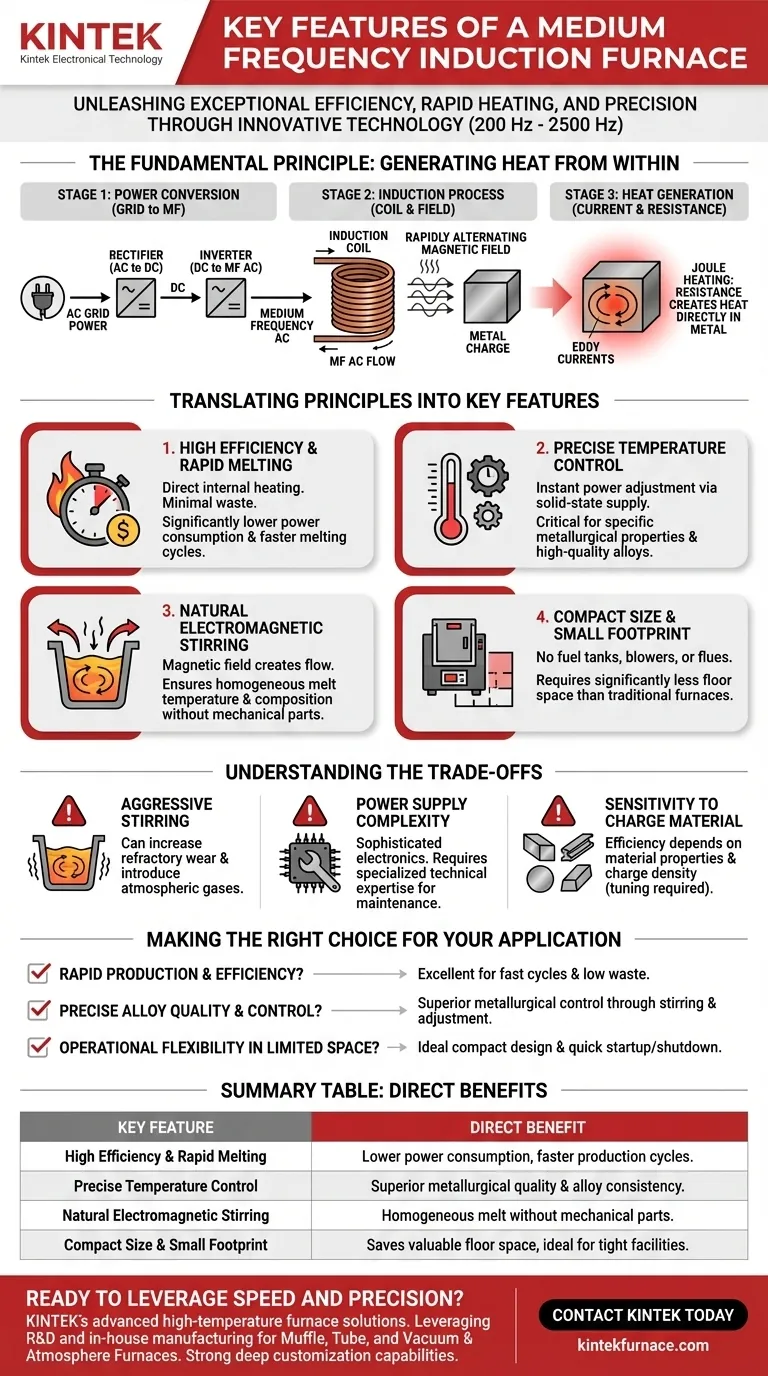

The Fundamental Principle: How Induction Generates Heat

To understand the features, you must first understand the core principle. An induction furnace does not burn fuel or use external heating elements to melt the charge. Instead, it turns the metal into its own heat source.

From Wall Power to Magnetic Field

The process begins by converting standard three-phase AC power from the grid into direct current (DC). This DC is then fed into an inverter, which converts it back into a single-phase, high-current alternating current, but at a much higher, "medium" frequency. This specially conditioned power is sent to the induction coil.

Inducing the Eddy Current

This medium-frequency alternating current flowing through the copper induction coil generates a powerful and rapidly alternating magnetic field inside the coil. When you place a conductive material like metal inside this field, the magnetic lines of force cut through the metal, inducing powerful electrical currents within it. These are known as eddy currents.

Resistance Creates Heat

The induced eddy currents are not useful on their own. However, as these currents swirl through the metal, they encounter the material's natural electrical resistance. This resistance to the flow of electrons generates immense, rapid heat throughout the metal, a phenomenon known as Joule heating.

Translating Principles into Key Features

The physics of induction heating directly leads to the furnace's most valued characteristics. Each feature is a direct consequence of generating heat inside the metal itself.

High Efficiency and Rapid Melting

Because heat is generated directly within the target material, energy transfer is extremely efficient. There is very little waste heat lost to the surrounding environment compared to a fuel-fired furnace, where heat must be transferred from a flame, through a crucible, and into the metal. This direct heating results in significantly lower power consumption and much faster melting cycles.

Precise Temperature Control

The amount of heat generated is directly proportional to the power supplied to the induction coil. The solid-state power supply can adjust this power virtually instantly. This allows for exceptionally precise and responsive temperature control, which is critical for producing high-quality alloys with specific metallurgical properties.

Natural Stirring Action

The powerful magnetic field and the flow of eddy currents create a natural stirring effect within the molten metal bath. This electromagnetic stirring ensures the melt is homogenous in both temperature and chemical composition, which is essential for creating uniform alloys without the need for mechanical stirring.

Compact Size and Small Footprint

Induction furnaces do not require fuel storage tanks, combustion blowers, or extensive exhaust flues. The primary components are the power supply cabinet and the furnace body (coil and crucible). This results in a much more compact, lightweight system that requires significantly less floor space than a traditional foundry furnace of the same capacity.

Understanding the Trade-offs

No technology is without its limitations. Objectivity requires acknowledging the trade-offs associated with medium frequency induction.

The Stirring Can Be Aggressive

While electromagnetic stirring is often a benefit, it can be too vigorous for certain applications. Overly aggressive stirring can increase refractory wear on the crucible lining and may introduce atmospheric gases into the melt, which is undesirable for some sensitive alloys.

Power Supply Complexity

The high-frequency power supply is a sophisticated piece of electronic equipment. While reliable, troubleshooting and repair require specialized technical expertise that may not be readily available. This contrasts with simpler fuel-based systems which can often be maintained with general mechanical knowledge.

Sensitivity to Charge Material

The efficiency of induction heating depends on the electrical resistivity and magnetic properties of the material being heated. The system must be properly tuned for the specific charge. Furthermore, the starting charge must be dense enough to couple effectively with the magnetic field; very loose scrap may melt inefficiently at first.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your operational goals.

- If your primary focus is rapid production and energy efficiency: The fast melting cycles and low energy waste of a medium frequency furnace make it an outstanding choice.

- If your primary focus is precise alloy quality and temperature control: The inherent stirring and instant power adjustment provide superior metallurgical control over most other methods.

- If your primary focus is operational flexibility in a limited space: Its compact design and quick startup/shutdown cycles are ideal for varied production schedules.

By understanding that a medium frequency furnace uses the metal's own resistance to create heat, you can fully leverage its advantages for cleaner, faster, and more controlled processing.

Summary Table:

| Key Feature | Direct Benefit |

|---|---|

| High Efficiency & Rapid Melting | Lower power consumption, faster production cycles. |

| Precise Temperature Control | Superior metallurgical quality and alloy consistency. |

| Natural Electromagnetic Stirring | Homogeneous melt without mechanical parts. |

| Compact Size & Small Footprint | Saves valuable floor space, ideal for tight facilities. |

Ready to leverage the speed and precision of a medium frequency furnace for your lab or foundry?

KINTEK's advanced high-temperature furnace solutions are engineered for performance. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced furnace technology. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact KINTEL today to discuss how a customized induction furnace solution can enhance your efficiency and product quality.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys