At their core, induction melting furnaces offer compelling advantages by combining a highly compact physical footprint with substantial long-term cost reductions. This is achieved through their exceptional energy efficiency, elimination of traditional fuel sources, and streamlined operational workflow.

While traditional melting often involves large, energy-intensive systems with significant operational overhead, induction technology provides a fundamentally more efficient alternative. It leverages precise electromagnetic heating to reduce waste, shrink the required floor space, and lower a wide range of operational costs.

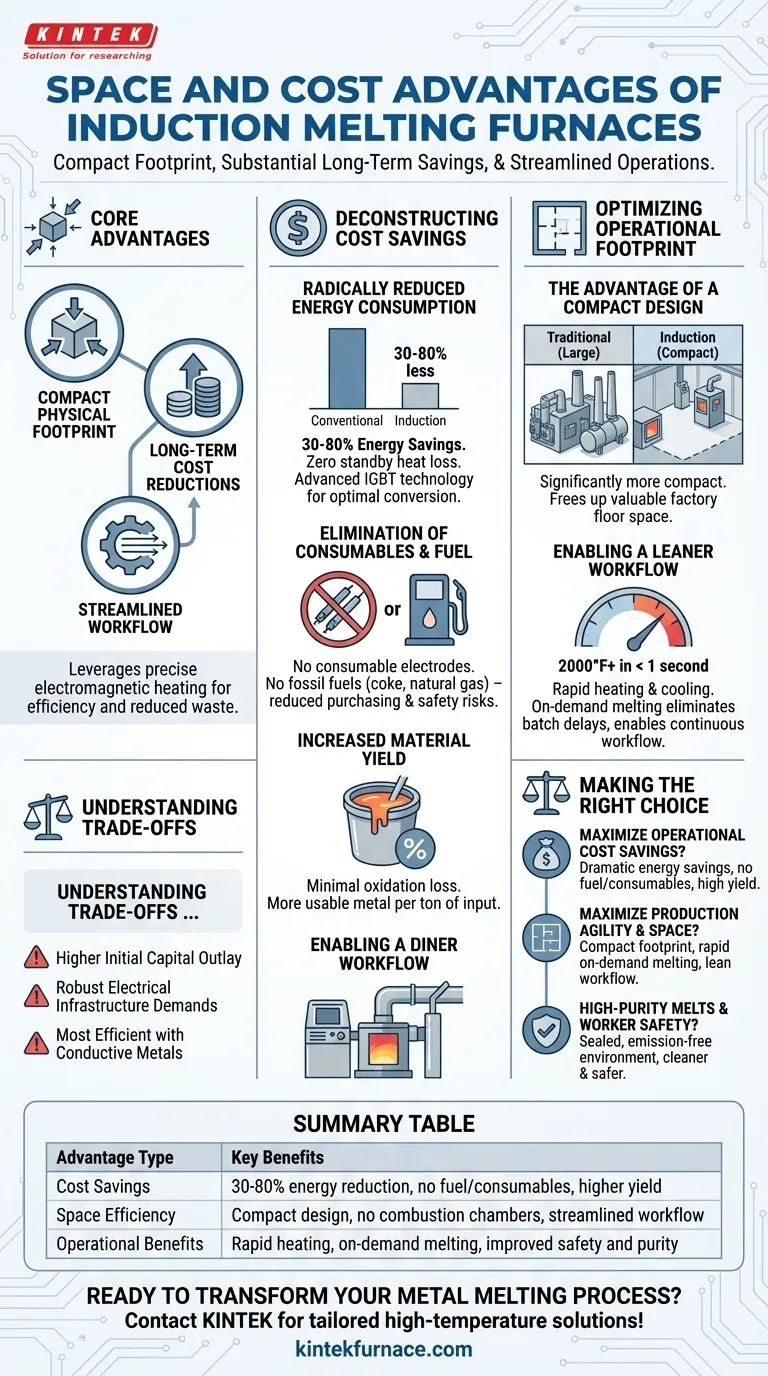

Deconstructing the Cost Savings

The financial benefits of induction furnaces extend far beyond the initial purchase price, impacting energy bills, material costs, and labor.

Radically Reduced Energy Consumption

Induction furnaces can deliver energy savings of 30–80% compared to conventional methods. This is due to their design, which heats the metal directly and internally.

There is zero standby heat loss, as energy is only consumed during the melting cycle. Advanced IGBT (Insulated-Gate Bipolar Transistor) technology and optimized frequency control ensure that nearly all electrical energy is converted into useful heat.

Elimination of Consumables and Fuel

Unlike arc furnaces, induction systems do not require consumable electrodes.

They also completely eliminate the need for fossil fuels like coke or natural gas, which removes fuel purchasing, storage, and handling costs, as well as associated safety risks.

Increased Material Yield

The induction process is exceptionally clean. When melting scrap or raw materials, there is minimal oxidation loss.

This means more of your input material is converted into usable molten metal, directly improving your yield and reducing the cost per ton of finished product.

Optimizing Your Operational Footprint

The design of an induction furnace fundamentally changes how it integrates into a facility, offering significant advantages in space and workflow.

The Advantage of a Compact Design

Induction furnaces are significantly more compact than their fuel-fired counterparts. They do not require large combustion chambers, fuel storage areas, or extensive flue gas and exhaust systems.

This frees up valuable factory floor space, which can be repurposed for other value-adding activities.

Enabling a Leaner Workflow

The technology enables incredible speed, capable of heating materials to over 2,000°F in under a second. The system also cools rapidly.

This allows for on-demand melting and a continuous workflow, eliminating the delays associated with batch processing. Furnaces can often be placed directly on the work floor, reducing material movement between different production areas.

Understanding the Trade-offs

While highly advantageous, induction technology is not a universal solution. A clear understanding of its limitations is critical for making an informed decision.

Higher Initial Capital Outlay

Induction melting systems often have a higher upfront purchase price compared to some simpler, traditional furnaces. The long-term operational savings are intended to offset this initial investment over the equipment's lifespan.

Electrical Infrastructure Demands

These furnaces are powerful electrical devices. Your facility must have a robust electrical supply and infrastructure capable of handling the significant power draw without disrupting other operations. Upgrading your power system can be a hidden but necessary cost.

Not Ideal for All Materials

Induction heating works by inducing an electrical current within the metal itself. It is therefore most efficient with electrically conductive metals. While versatile, its performance and efficiency can vary when melting materials with poor conductivity or when processing large amounts of non-metallic slag.

Making the Right Choice for Your Operation

The decision to invest in an induction furnace should be directly tied to your specific operational and business goals.

- If your primary focus is minimizing long-term operational costs: The dramatic energy savings, elimination of fuel and consumables, and high material yield make induction a superior financial choice over time.

- If your primary focus is maximizing production agility and floor space: The compact footprint and rapid, on-demand melting cycles allow for a leaner, more integrated, and space-efficient facility layout.

- If your primary focus is high-purity melts and worker safety: The sealed, emission-free environment provides unparalleled control over metal purity and creates a much safer and cleaner workplace than combustion-based methods.

Ultimately, choosing an induction furnace is a strategic investment in precision, efficiency, and a more modern, sustainable production environment.

Summary Table:

| Advantage Type | Key Benefits |

|---|---|

| Cost Savings | 30-80% energy reduction, no fuel or consumables, higher material yield |

| Space Efficiency | Compact design, no combustion chambers, streamlined workflow |

| Operational Benefits | Rapid heating, on-demand melting, improved safety and purity |

Ready to transform your metal melting process with advanced induction furnaces? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique needs. Contact us today to discuss how we can boost your efficiency and reduce costs!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications