In the context of TiCp/Fe composite preparation, the medium-frequency induction furnace serves as the critical vessel for rapidly melting matrix metals, specifically manganese steel. Its primary function is to bring the molten steel to a precise target temperature of 1550 ± 10 °C, ensuring the metal achieves the high fluidity and accurate chemical composition necessary for successful composite formation.

The medium-frequency induction furnace is not merely a heating source; it is a process control tool. By combining rapid heating with inherent electromagnetic stirring, it ensures the molten matrix is both chemically homogenous and physically fluid enough to facilitate optimal composite structure.

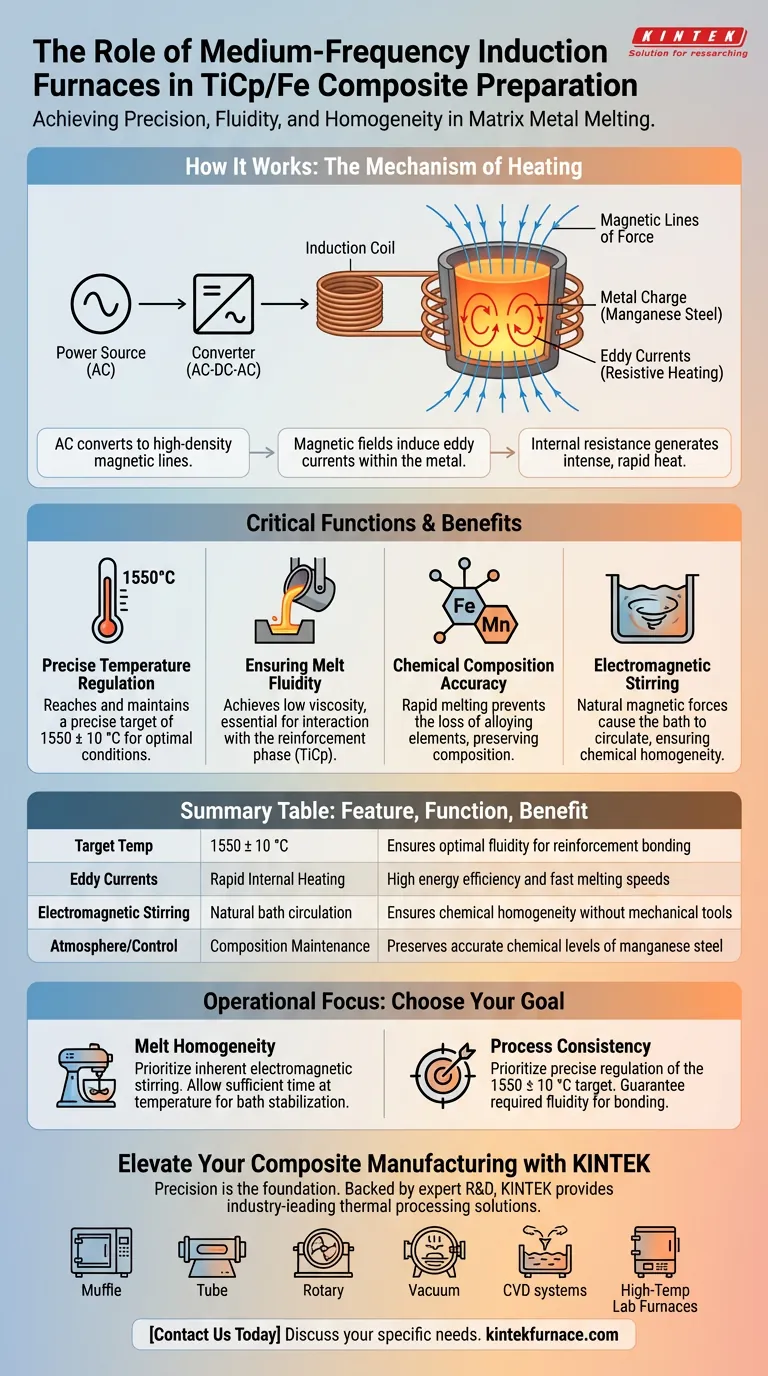

The Mechanism of Heating

To understand why this furnace is effective for TiCp/Fe composites, it is necessary to understand how it generates heat.

Creation of Eddy Currents

The furnace operates by converting alternating current into direct current, and then back into an adjustable alternating current. This current flows through an induction coil, creating high-density magnetic lines of force.

Resistive Heating

When these magnetic fields cut through the metal charge (the matrix metal), they induce eddy currents within the material. The resistance of the metal to these internal currents generates intense heat directly inside the charge, resulting in rapid melting.

Critical Functions in Composite Preparation

The primary reference highlights specific requirements for TiCp/Fe composites that this furnace addresses.

Precise Temperature Regulation

Achieving a specific temperature window is non-negotiable for this process. The furnace is calibrated to reach 1550 ± 10 °C.

Ensuring Melt Fluidity

At this precise temperature, the manganese steel matrix achieves excellent fluidity. This low viscosity is essential for the subsequent interaction between the matrix and the reinforcement phase (TiCp).

Chemical Composition Accuracy

The rapid melting capabilities of the induction furnace help maintain the accurate chemical composition of the steel. Prolonged exposure to heat sources in other furnace types can sometimes lead to the loss of alloying elements.

Electromagnetic Stirring

Perhaps the most distinct advantage is the natural electromagnetic stirring effect. The magnetic forces that heat the metal also cause the liquid bath to circulate, ensuring a uniform distribution of components without the need for mechanical agitators.

Understanding the Operational Factors

While highly effective, the use of medium-frequency induction requires careful management of operational variables.

Power Frequency Management

The system relies on converting power frequency to an adjustable output. Precise control over this conversion is required to maintain the stability of the eddy currents and, consequently, the temperature stability.

Energy Efficiency and Speed

Because heat is generated within the metal rather than applied externally, the process is highly efficient. However, this rapid heating requires operators to monitor the melt closely to prevent overshooting the narrow 1550 °C target window.

Making the Right Choice for Your Goal

The medium-frequency induction furnace is the standard for high-quality metal matrix composites. However, your operational focus will dictate how you utilize its features.

- If your primary focus is Melt Homogeneity: Rely on the inherent electromagnetic stirring to mix the liquid components, ensuring you allow enough time at temperature for the bath to stabilize.

- If your primary focus is Process Consistency: Prioritize the precise regulation of the 1550 ± 10 °C temperature target to guarantee the fluidity required for the matrix to properly bond with the composite reinforcement.

By leveraging the induction furnace's ability to simultaneously heat and stir, you ensure the foundational integrity of your TiCp/Fe composite.

Summary Table:

| Feature | Function in TiCp/Fe Preparation | Benefit |

|---|---|---|

| Target Temp | 1550 ± 10 °C | Ensures optimal fluidity for reinforcement bonding |

| Eddy Currents | Rapid Internal Heating | High energy efficiency and fast melting speeds |

| Electromagnetic Stirring | Natural bath circulation | Ensures chemical homogeneity without mechanical tools |

| Atmosphere/Control | Composition Maintenance | Preserves accurate chemical levels of manganese steel |

Elevate Your Composite Manufacturing with KINTEK

Precision is the foundation of high-performance TiCp/Fe composites. Backed by expert R&D and world-class manufacturing, KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces designed to meet your most rigorous thermal processing requirements.

Whether you need precise temperature regulation or customizable systems for unique material challenges, our engineering team is ready to deliver the perfect solution. Contact us today to discuss your specific needs and discover how our advanced heating technology can optimize your production efficiency and material integrity.

Visual Guide

References

- Shengnian Zhao, Yehua Jiang. Microstructure and Properties of TiCp/Fe Hierarchical Composites Prepared by a New Pressure Infiltration Method. DOI: 10.3390/ma17061325

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What factors should be considered when selecting a crucible for an induction-heated vacuum furnace? Ensure High-Purity Melts and Efficiency

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What is the role of vacuum arc melting equipment in the preparation of Ti-33Al based alloy button ingots?

- How does the vacuum arc melting process work? Achieve High-Purity Metals for Demanding Applications

- Why are electromagnetic stirring and repeated melting cycles necessary? Achieving Homogeneity in (AlTiV)100−xCrx Alloys

- What role does the induction coil play in an induction melting furnace? It's the Engine of Efficient Melting

- What industries primarily use vacuum induction melting furnaces? Essential for High-Performance Alloys

- Importance of Induction Heating System and Coil Design in ODS Steel Bonding: Optimize Your Thermal Profile