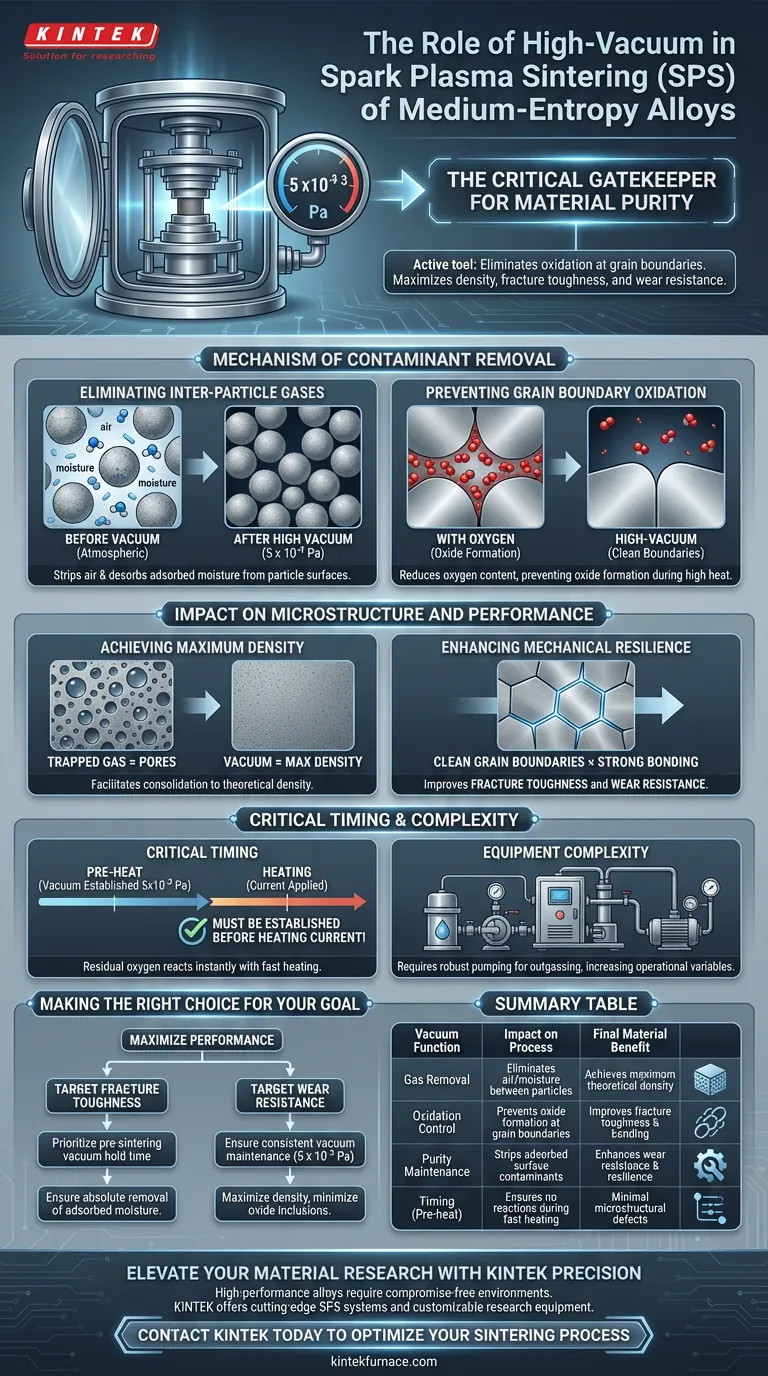

A high-vacuum environment is the critical gatekeeper for material purity in the Spark Plasma Sintering (SPS) of medium-entropy alloys. By establishing a specific vacuum level of 5 x 10^-3 Pa before the heating cycle begins, the process ensures the complete removal of air and adsorbed moisture trapped between powder particles.

Core Takeaway The vacuum environment is not merely about emptiness; it is an active processing tool that eliminates oxidation at the grain boundaries. By stripping away oxygen and moisture, the vacuum maximizes the density of the sintered body, directly resulting in superior fracture toughness and wear resistance in the final alloy.

The Mechanism of Contaminant Removal

Eliminating Inter-particle Gases

The primary function of the vacuum is to evacuate the physical gaps between the raw alloy powders.

Before the temperature rises, a vacuum level of 5 x 10^-3 Pa is established to strip away atmospheric air.

This step also desorbs moisture that has adhered to the surface of the powder particles, ensuring the starting material is pristine.

Preventing Grain Boundary Oxidation

The most significant threat to medium-entropy alloys during sintering is oxygen contamination.

If oxygen is present during the high-heat phase, it reacts with the metal surfaces to form oxide layers.

The high-vacuum environment drastically reduces oxygen content, specifically preventing these oxides from forming at the grain boundaries.

Impact on Microstructure and Performance

Achieving Maximum Density

Removing gases is a prerequisite for achieving a fully dense material.

Trapped gas acts as a barrier to densification, leading to pores or voids in the final product.

By operating in a high vacuum, SPS facilitates the consolidation of particles into a solid body that approaches its theoretical density.

Enhancing Mechanical Resilience

The cleanliness of the grain boundaries defines the mechanical success of the alloy.

Clean boundaries—free from brittle oxides—allow for better atomic bonding between grains.

This microstructural purity directly translates to macroscopic performance, specifically improving fracture toughness and wear resistance.

Understanding the Trade-offs

The Critical Timing of Vacuum Application

The benefits of a vacuum are lost if the timing is incorrect.

The vacuum must be fully established to the 5 x 10^-3 Pa level before the heating current is applied.

Because SPS utilizes extremely fast heating rates, any residual oxygen remaining when the current starts will instantly react with the alloy, locking in defects that cannot be removed later.

Equipment Complexity

Maintaining a high vacuum adds variables to the manufacturing process.

It requires robust pumping systems capable of handling outgassing from the powders without losing pressure.

While this ensures quality, it increases the operational complexity compared to non-vacuum sintering methods.

Making the Right Choice for Your Goal

To maximize the performance of your medium-entropy alloys, you must align your processing parameters with your mechanical targets.

- If your primary focus is fracture toughness: Prioritize the pre-sintering vacuum hold time to ensure absolute removal of adsorbed moisture at grain boundaries.

- If your primary focus is wear resistance: Ensure your vacuum system can maintain 5 x 10^-3 Pa consistently to maximize final density and minimize oxide inclusions.

True high-performance sintering relies not just on heat and pressure, but on the pristine environment that allows the material chemistry to function without interference.

Summary Table:

| Vacuum Function | Impact on Process | Final Material Benefit |

|---|---|---|

| Gas Removal | Eliminates air and moisture between particles | Achieves maximum theoretical density |

| Oxidation Control | Prevents oxide formation at grain boundaries | Improves fracture toughness and bonding |

| Purity Maintenance | Strips adsorbed surface contaminants | Enhances wear resistance and resilience |

| Timing (Pre-heat) | Ensures no reactions during fast heating | Minimal microstructural defects |

Elevate Your Material Research with KINTEK Precision

High-performance alloys require an environment without compromise. Backed by expert R&D and manufacturing, KINTEK offers cutting-edge Spark Plasma Sintering (SPS) systems, alongside our Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your unique research needs.

Whether you are targeting superior fracture toughness or maximum density, our equipment provides the high-vacuum stability (5 x 10^-3 Pa) essential for your success. Contact KINTEK today to optimize your sintering process and bring your material performance to the next level.

Visual Guide

References

- Yubo Zhao, Oleksandr Тіsov. Enhancing Reciprocating Wear Resistance of Co37Cr28Ni31Al2Ti2 Spark Plasma Sintered Medium-Entropy Alloy via TiC Addition. DOI: 10.3390/ma18020442

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the challenges of relying solely on a vacuum in furnace applications? Overcome Key Operational Hurdles

- Why is a vacuum deposition system required for BL-MoS2 doping? Achieve Nanogram-Level Precision & Purity

- How does a high-temperature vacuum furnace convert PDA into nitrogen-doped carbon shells? Master Carbonization Control

- What applications does a vacuum melting furnace have in research? Unlock High-Purity Material Development

- What are the advantages of vacuum carburizing over conventional atmosphere-carburizing methods? Boost Quality and Efficiency in Case Hardening

- How is furnace brazing utilized in the electronics and semiconductor industries? Master Precision Joining for High-Reliability Components

- What factors are critical for the proper functioning of a vacuum furnace? Maximize Material Purity and Process Control

- What is the significance of vacuum furnaces in metal melting? Achieve Ultra-Pure, High-Performance Metals