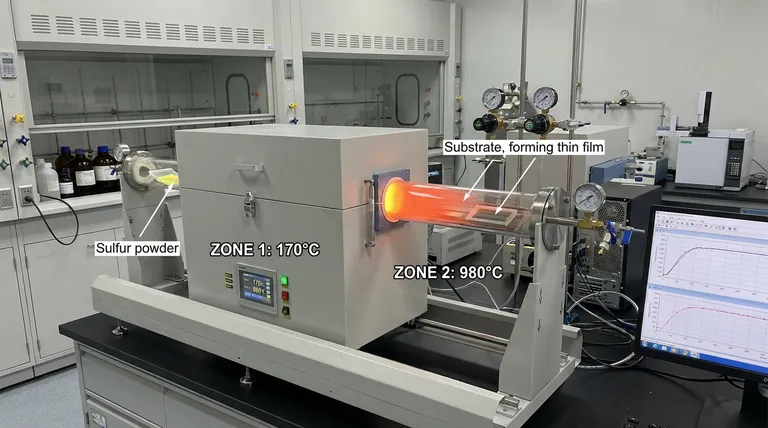

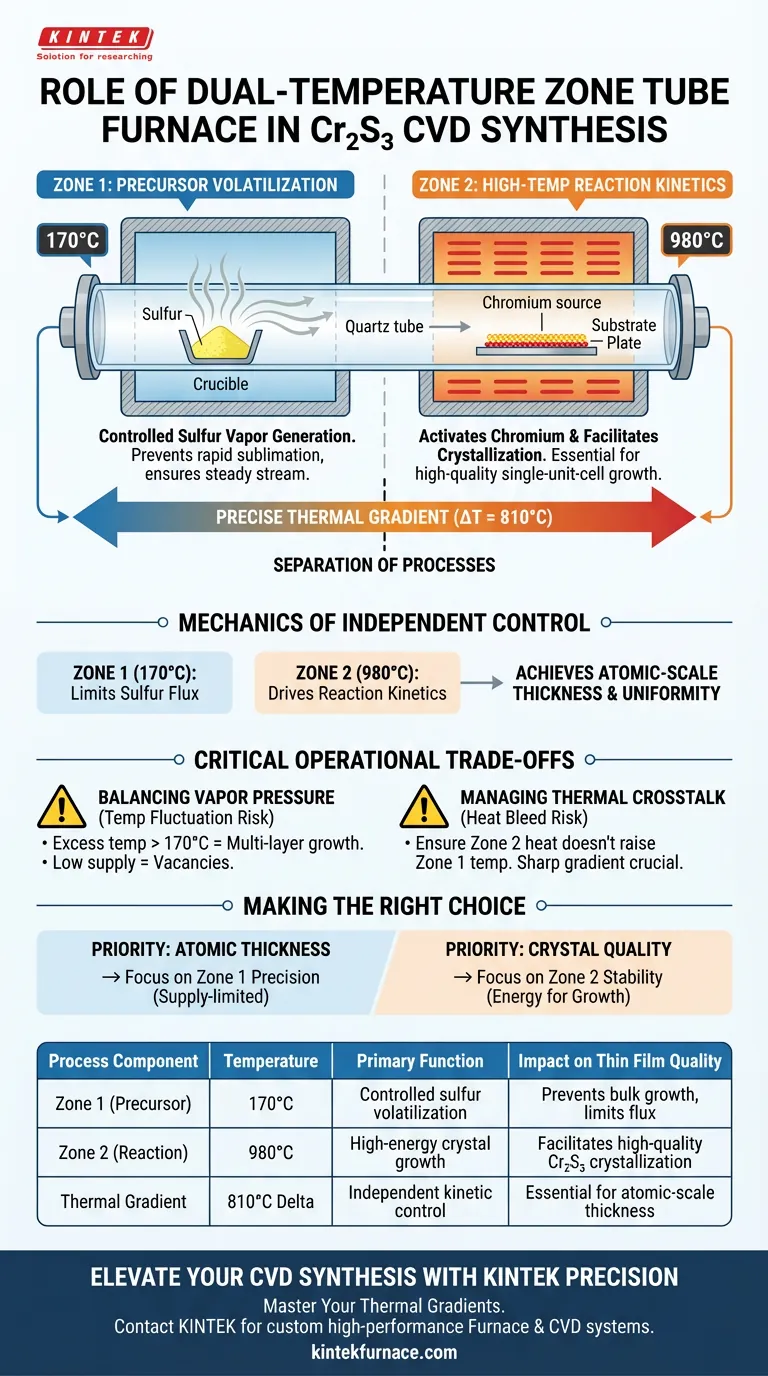

The dual-temperature zone tube furnace acts as the primary regulatory system for synthesizing single-unit-cell thick chromium sulfide ($Cr_2S_3$) via Chemical Vapor Deposition (CVD). It creates a precisely controlled thermal gradient that separates the vaporization of the sulfur precursor at $170^{\circ}C$ from the high-temperature growth reaction at $980^{\circ}C$. This separation allows for independent control over precursor supply and reaction kinetics, which is essential for achieving atomic-scale thickness and uniformity.

The core capability of this equipment is the decoupling of precursor evaporation from crystal growth. By maintaining two distinct thermal environments, the system ensures that the volatility of sulfur does not compromise the high energy required for the crystallization of chromium sulfide on the substrate.

The Mechanics of Independent Thermal Control

To grow materials as thin as a single unit cell, the environment must be rigorously controlled. A dual-zone furnace achieves this by splitting the CVD process into two physically and thermally distinct stages.

Zone 1: Controlled Precursor Volatilization

The first temperature zone is dedicated strictly to the sulfur source.

In this zone, the furnace maintains a relatively low temperature of $170^{\circ}C$.

The objective here is to generate a steady, controlled stream of sulfur vapor without inducing rapid, uncontrolled sublimation that would overwhelm the reaction downstream.

Zone 2: High-Temperature Reaction Kinetics

The second temperature zone houses the chromium source and the growth substrate.

This zone is heated to a much higher temperature of $980^{\circ}C$.

This high thermal energy is necessary to activate the chromium precursor and facilitate the chemical reaction on the substrate surface, ensuring high-quality crystallization.

Regulating Film Thickness via Gradients

The interaction between these two zones determines the thickness of the final material.

By independently regulating the rate at which sulfur evaporates (Zone 1) and the rate at which the crystal forms (Zone 2), the system prevents the deposition of excess material.

This balance is the specific mechanism that enables the formation of atomic-scale thin films rather than bulk crystals.

Critical Operational Trade-offs

While a dual-zone furnace provides precision, it introduces complexities that must be managed to ensure reproducibility.

Balancing Vapor Pressure and Deposition Rate

There is a delicate trade-off between the supply rate of sulfur and the growth rate of the film.

If the temperature in Zone 1 fluctuates even slightly above $170^{\circ}C$, the vapor pressure of sulfur may spike, leading to multi-layer growth rather than the desired single-unit-cell thickness.

Conversely, if the supply is too low, the film may suffer from vacancies or incomplete coverage.

Managing Thermal Crosstalk

Although the zones are controlled independently, heat transfer between zones can occur.

Operators must ensure that the high heat from Zone 2 ($980^{\circ}C$) does not bleed upstream and unintentionally raise the temperature of the sulfur source in Zone 1.

Failure to maintain this sharp thermal gradient results in unstable precursor flux and non-uniform film growth.

Making the Right Choice for Your Goal

To maximize the effectiveness of a dual-temperature zone furnace for $Cr_2S_3$ synthesis, you must tune your parameters based on your specific quality metrics.

- If your primary focus is atomic-scale thickness: Prioritize the precision of the first zone ($170^{\circ}C$) to strictly limit the sulfur vapor supply, ensuring the reaction is supply-limited.

- If your primary focus is crystal quality and domain size: Focus on stabilizing the second zone ($980^{\circ}C$) to maximize the thermodynamic energy available for defect-free nucleation and growth.

Mastering the thermal gradient is the only way to transition from random deposition to controlled, single-unit-cell synthesis.

Summary Table:

| Process Component | Temperature | Primary Function | Impact on Thin Film Quality |

|---|---|---|---|

| Zone 1 (Precursor) | 170°C | Controlled sulfur volatilization | Prevents bulk growth by limiting precursor flux |

| Zone 2 (Reaction) | 980°C | High-energy crystal growth | Facilitates high-quality crystallization of Cr2S3 |

| Thermal Gradient | 810°C Delta | Independent kinetic control | Essential for achieving atomic-scale thickness |

Elevate Your CVD Synthesis with KINTEK Precision

Precise thermal gradients are the difference between bulk material and atomic-scale innovation. At KINTEK, we understand the rigorous demands of $Cr_2S_3$ synthesis. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to eliminate thermal crosstalk and ensure independent zone stability.

Whether you are growing single-unit-cell thick films or scaling complex chemical vapor deposition processes, our laboratory furnaces are fully customizable to meet your unique research needs.

Ready to master your thermal gradients?

Contact KINTEK today to discuss your custom furnace solution.

Visual Guide

References

- Luying Song, Jun He. Robust multiferroic in interfacial modulation synthesized wafer-scale one-unit-cell of chromium sulfide. DOI: 10.1038/s41467-024-44929-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- In which fields are CVD furnaces widely applied? Essential for Semiconductors, Aerospace, and More

- What is the role of a low-pressure hot-wall CVD system in graphene synthesis on silver foil? Expert Insights

- What is low temperature vapor deposition? A Guide to Coating Heat-Sensitive Materials

- What is the specific function of a thermal evaporation system in IPSLS growth? Precision Precursor Deposition

- What advantages does the DLI-PP-CVD system offer for MoS2 nanosheet growth? Achieve Molecular Precision & Scalability

- What is the main development direction for improving Chemical Vapor Deposition (CVD) technology? Advance with Low-Temperature, High-Vacuum Solutions

- In what way are CVD systems applied to gas purification? Engineer Advanced Catalysts for Cleaner Synthesis Gas

- What happens during the chemical reactions in CVD? Master Thin Film Deposition for Your Lab