At its core, the chemical reaction in Chemical Vapor Deposition (CVD) is a controlled process where gas-phase chemicals, known as precursors, are energized within a chamber. This energy forces them to react or decompose on a heated surface, called a substrate, where they form a new, solid thin film, building it up atom by atom.

Chemical Vapor Deposition is not a single event, but a highly engineered sequence: introducing specific gases, activating them with energy, and directing their reaction onto a surface to build a solid material with precisely controlled properties.

The Fundamental Stages of a CVD Reaction

To truly understand CVD, you must view it as a multi-stage process. Each stage is a critical control point that determines the final quality of the deposited film.

Introduction of Precursors

The process begins by introducing one or more volatile precursor gases into a reaction chamber, which is often under vacuum. These precursors are specifically chosen because they contain the atomic elements required for the final film.

Precise control over the gas flow rates is essential, as this determines the concentration of reactants available for the deposition.

Energy Input and Activation

The stable precursor molecules will not react on their own. They must be activated by an external energy source. This energy breaks the chemical bonds in the precursor gases, creating highly reactive chemical species, sometimes called fragments or radicals.

Common energy sources include high temperature (Thermal CVD), an electrical field to create a plasma (Plasma-Enhanced CVD or PECVD), or even high-intensity light (Photo-assisted CVD).

Reaction and Deposition on the Substrate

The highly reactive gas species then travel to the substrate, which is a base material (like a silicon wafer or a piece of glass) that has been placed in the chamber.

Once on the substrate surface, these species undergo chemical reactions. They may combine with other reactive species or further decompose, ultimately forming a stable, solid material that chemically bonds to the substrate surface.

Film Growth and Byproduct Removal

This deposition process occurs continuously, building the solid material layer by layer to form a thin film. The thickness of this film is controlled by the duration of the process.

The chemical reactions also generate unwanted gaseous byproducts, which are continuously pumped out of the reaction chamber to prevent them from contaminating the film.

Understanding the Trade-offs and Challenges

The power of CVD lies in its precision, but this precision comes with inherent complexities and trade-offs that engineers must manage.

Thermal CVD vs. Plasma-Enhanced CVD

Thermal CVD uses very high temperatures (often >600°C) to drive reactions. This typically produces very pure, high-quality, crystalline films. However, these temperatures can damage or melt many substrates, such as plastics or certain electronic components.

Plasma-Enhanced CVD (PECVD) uses a plasma to activate the precursors at much lower temperatures (often ~350°C). This makes it suitable for temperature-sensitive substrates, but the films may be less crystalline (amorphous) and can sometimes have impurities from the plasma process.

Precursor Selection

Choosing the right precursor is a significant chemical engineering challenge. It must be volatile enough to be transported as a gas but stable enough not to react prematurely. Crucially, it must decompose cleanly on the substrate without introducing unwanted atomic impurities into the final film.

Achieving Uniformity

Ensuring the film has a consistent thickness and composition across the entire substrate surface is a primary challenge. This requires exceptionally fine control over temperature gradients, gas flow dynamics, and pressure throughout the chamber to ensure all parts of the substrate receive the same flux of reactive species.

Making the Right Choice for Your Goal

Your choice of CVD parameters is dictated entirely by the desired properties of your final material.

- If your primary focus is maximum purity and crystallinity for a robust material: Thermal CVD is often the superior method, provided your substrate can withstand the intense heat.

- If your primary focus is depositing a film on a temperature-sensitive component like an electronic sensor or polymer: Plasma-Enhanced CVD (PECVD) is the necessary choice to avoid damaging the underlying substrate.

- If your primary focus is coating a complex, three-dimensional object: You must prioritize a process with meticulous control over gas flow and pressure to ensure uniform, conformal coverage.

Understanding the principles of these chemical reactions allows you to deliberately engineer materials from the atomic level upwards.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| Introduction of Precursors | Volatile gases enter chamber | Supply atomic elements for film |

| Energy Input and Activation | Apply heat, plasma, or light | Create reactive species from precursors |

| Reaction and Deposition | Species bond to substrate surface | Form solid thin film atom by atom |

| Film Growth and Byproduct Removal | Continuous layer buildup and gas removal | Control thickness and prevent contamination |

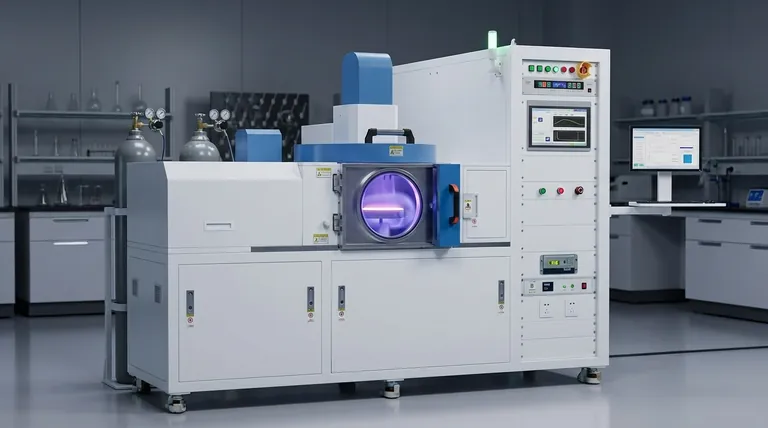

Ready to enhance your lab's capabilities with tailored CVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior thin film deposition. Contact us today to discuss how we can optimize your CVD processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition