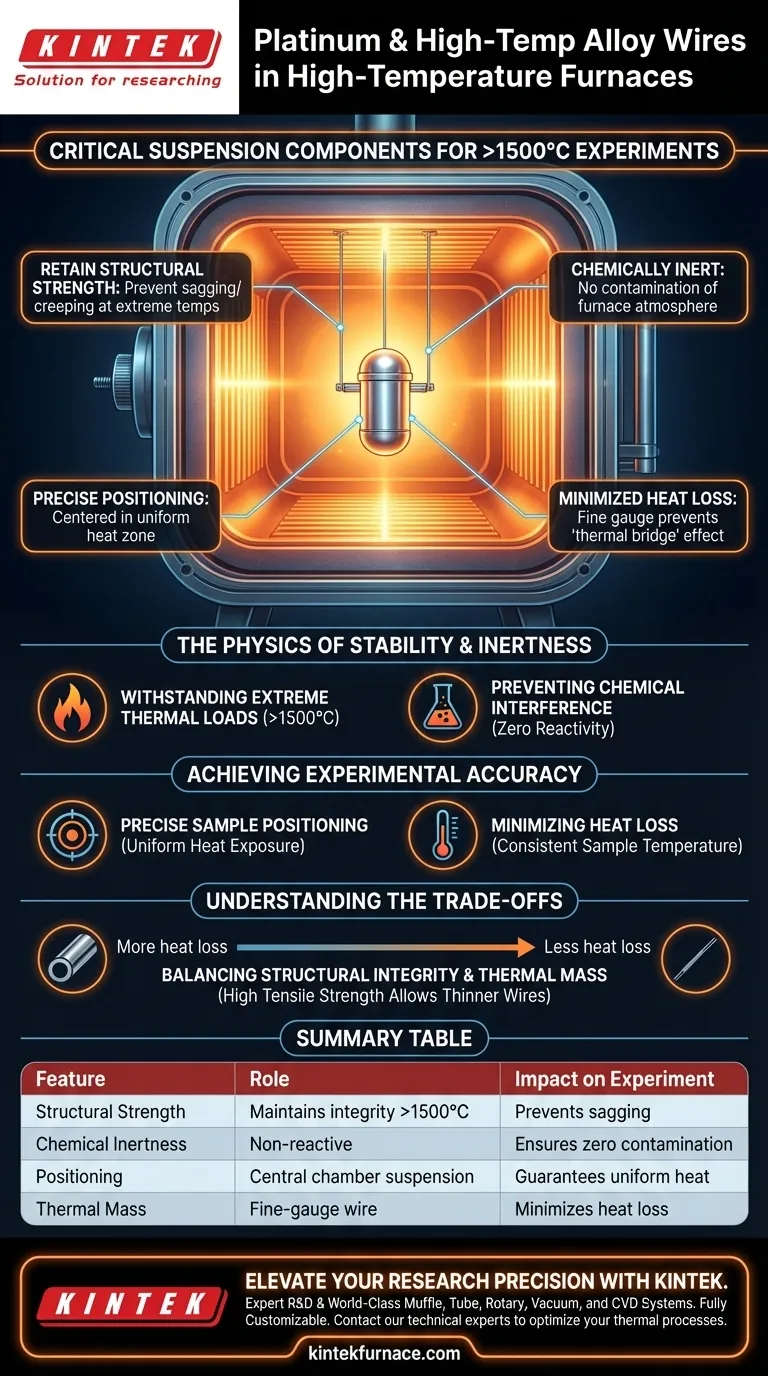

Platinum and high-temperature alloy wires act as critical suspension components designed to maintain structural integrity in experiments exceeding 1500 degrees Celsius. They physically secure encapsulated samples in the precise center of the furnace chamber while preventing chemical contamination and minimizing thermal interference.

The core value of using these specific alloys lies in their ability to decouple the sample from the furnace environment. By combining extreme heat resistance with a fine form factor, they ensure the sample’s internal temperature remains consistent with the furnace's thermocouple readings.

The Physics of Stability and Inertness

Withstanding Extreme Thermal Loads

Standard suspension materials fail when subjected to the extreme conditions of high-temperature furnaces. Platinum and high-temperature alloys are specifically selected because they retain structural strength at temperatures above 1500°C.

This capability prevents the suspension system from sagging, creeping, or breaking during prolonged heating cycles.

Preventing Chemical Interference

In addition to thermal resilience, these wires must not alter the experiment's chemistry. They are designed to remain chemically inert relative to the furnace atmosphere.

This ensures that the suspension mechanism does not introduce contaminants or react with the environment, preserving the purity of the experimental conditions.

Achieving Experimental Accuracy

Precise Sample Positioning

The geometry of a furnace creates specific thermal gradients, making the physical location of the sample critical. These wires allow for the stable positioning of encapsulated samples directly in the center of the furnace chamber.

Central placement ensures the sample is exposed to the most uniform heat zone, reducing variables caused by uneven heating.

Minimizing Heat Loss

The gauge (thickness) of the suspension wire plays a pivotal role in thermal data accuracy. These specific wires utilize a fine gauge to reduce the physical mass connecting the sample to the outside environment.

A thicker wire would act as a "thermal bridge," conducting heat away from the sample. By using a fine gauge, heat loss is minimized, ensuring the sample temperature stays highly consistent with the temperature measured by the furnace thermocouples.

Understanding the Trade-offs

Balancing Structural Integrity and Thermal Mass

The primary challenge in suspension design is the relationship between the wire's thickness and experimental accuracy. While a thicker wire offers more security, it increases the risk of conductive heat loss, which causes a discrepancy between the set temperature and the actual sample temperature.

Therefore, the system relies on the high tensile strength of platinum/alloys to allow for the thinnest possible wire gauge. You are trading raw mechanical bulk for thermal precision, relying on material quality rather than material volume to hold the weight.

Making the Right Choice for Your Goal

To ensure the validity of your high-temperature experiments, select your suspension material based on your specific precision requirements.

- If your primary focus is Thermal Accuracy: Prioritize wires with the finest possible gauge to minimize heat loss and ensure the sample matches the thermocouple reading.

- If your primary focus is Structural Security: Ensure the alloy selected is rated for structural retention specifically above your target temperature (e.g., >1500°C) to prevent creep.

Success in high-temperature experiments depends on minimizing the suspension system's physical and thermal footprint while maintaining absolute position.

Summary Table:

| Feature | Platinum/High-Temp Alloy Role | Impact on Experiment |

|---|---|---|

| Structural Strength | Maintains integrity above 1500°C | Prevents sagging or sample displacement |

| Chemical Inertness | Non-reactive material properties | Ensures zero contamination of the furnace atmosphere |

| Positioning | Enables central chamber suspension | Guarantees exposure to the uniform heat zone |

| Thermal Mass | Fine-gauge wire construction | Minimizes heat loss to maintain thermocouple accuracy |

Elevate Your Research Precision with KINTEK

Don't let subpar suspension components compromise your high-temperature data. At KINTEK, we understand that every degree matters. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique experimental challenges.

Whether you are working with delicate alloys or require extreme thermal stability, our lab high-temp furnaces are designed to work in harmony with your specialized materials. Ready to optimize your thermal processes? Contact our technical experts today to find the perfect solution for your lab.

Visual Guide

References

- Hamed Abdeyazdan, Evgueni Jak. Phase equilibria in the CuO <sub>0.5</sub> –SbO <sub>1.5</sub> –SiO <sub>2</sub> system. DOI: 10.1111/jace.70123

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the main advantages of ceramic infrared heaters? Achieve Instant, Efficient Heating for Your Space

- What is watt-density and why is it important in heating element design? Ensure Efficiency and Longevity

- What are the main differences between SiC and MoSi2 heating elements? Choose the Right Element for Your High-Temp Needs

- What is the density of MoSi2 heating elements? Understand the Key to High-Temp Performance

- What are the primary functions of a tantalum (Ta) tube in the synthesis of KBaBi? Essential Corrosion Resistance

- What is the role of resistivity in heating elements? Unlock Efficient Heat Generation for Your Applications

- What is the composition and key properties of Copper Nickel (CuNi) alloys? Discover Their Stability and Durability

- What is a band heater and how is it used? Boost Efficiency in Industrial Heating