At its core, a Copper Nickel (CuNi) alloy is a strategic blend of metals designed for stability and durability. A common formulation consists of approximately 66% copper, 30% nickel, 2% iron, and 2% manganese, giving it a unique set of properties including high electrical resistivity, an extremely low temperature coefficient, and excellent resistance to oxidation and corrosion.

The true value of Copper Nickel alloys lies not in any single property, but in their combination: they provide stable, predictable electrical performance across a wide range of temperatures while simultaneously offering exceptional resistance to corrosive environments, particularly saltwater.

Deconstructing the Composition

Understanding why CuNi alloys are so effective begins with their individual components. Each element plays a deliberate role in the final material's performance.

The Copper-Nickel Foundation

Copper (Cu) and Nickel (Ni) form the alloy's backbone. They are fully miscible, meaning they can be blended in any proportion to form a single, uniform solid solution. This structure is fundamental to the alloy's inherent strength and corrosion resistance.

The Role of Iron and Manganese

The small additions of Iron (Fe) and Manganese (Mn) are critical for enhancing specific properties. Iron significantly improves resistance to erosion and corrosion, especially in fast-flowing seawater. Manganese acts as a deoxidizer during the melting process, improving the alloy's workability and structural integrity.

Key Properties Explained

The specific composition of CuNi alloys results in a profile optimized for demanding electrical and marine applications.

High Electrical Resistivity

With a resistivity of 50 μΩ-cm, CuNi is a relatively poor conductor of electricity. This makes it ideal for applications like resistors, where the goal is to impede the flow of current and dissipate electrical energy.

Extremely Low Temperature Coefficient

This is arguably the most critical electrical property of CuNi. Its temperature coefficient of resistance is exceptionally low at 0.00006 /°C. This means that as the alloy heats up or cools down, its electrical resistance remains almost perfectly constant. This stability is essential for precision measurement devices like thermocouples, strain gauges, and shunts.

Good Corrosion and Oxidation Resistance

CuNi alloys are highly resistant to corrosion from a wide range of sources, most notably saltwater. This, combined with good resistance to oxidation at elevated temperatures and a melting point of 1280°C, makes the material durable for heat exchangers, condenser tubes, and marine hardware.

High Density

The specific gravity of 8.86 gm/cm³ indicates that CuNi is a dense and heavy material. This must be factored into any design where weight is a primary concern.

Understanding the Trade-offs

No material is perfect for every situation. The strengths of CuNi in some areas create limitations in others.

Not Ideal for High-Temperature Heating

While CuNi has good heat resistance, it is not the top choice for high-temperature heating elements. Other materials, like Nickel-Chromium alloys (80% Ni, 20% Cr), offer a higher melting point (1400°C) and superior oxidation resistance specifically for applications that require generating intense heat.

Cost and Weight Considerations

The high nickel content makes CuNi alloys more expensive than common carbon steels or aluminum alloys. Its high density also means that for a given volume, a CuNi component will be heavier, which can be a significant factor in large-scale or mobile applications.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to your primary technical goal.

- If your primary focus is stable resistance for instrumentation: CuNi is the ideal choice due to its near-zero temperature coefficient, ensuring measurement accuracy across temperature shifts.

- If your primary focus is saltwater corrosion resistance: CuNi alloys, often known as cupronickel, are the industry standard for marine hardware, piping, and heat exchangers.

- If your primary focus is generating high heat: A Nickel-Chromium alloy is a better selection, as it is engineered for superior performance and longevity at extreme operating temperatures.

Ultimately, choosing CuNi is a decision to prioritize exceptional environmental resilience and electrical stability for your project.

Summary Table:

| Property | Value/Description |

|---|---|

| Composition | ~66% Cu, 30% Ni, 2% Fe, 2% Mn |

| Electrical Resistivity | 50 μΩ-cm |

| Temperature Coefficient | 0.00006 /°C |

| Melting Point | 1280°C |

| Density | 8.86 gm/cm³ |

| Key Applications | Resistors, thermocouples, marine hardware, heat exchangers |

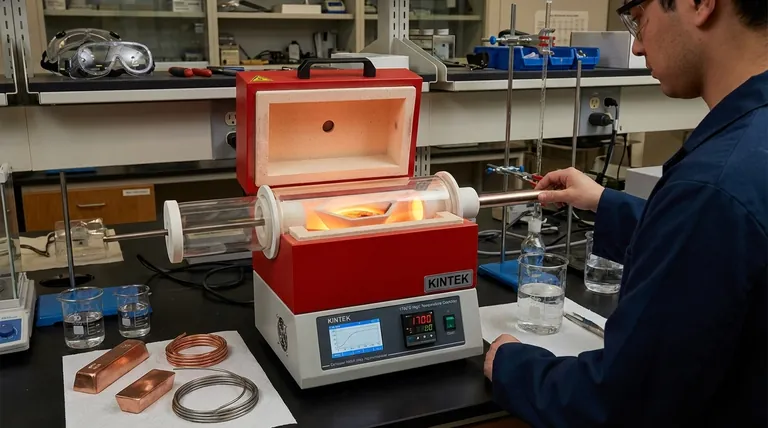

Need a high-temperature furnace for testing CuNi alloys or other materials? KINTEK offers advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique experimental needs. Contact us today to enhance your lab's capabilities!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability