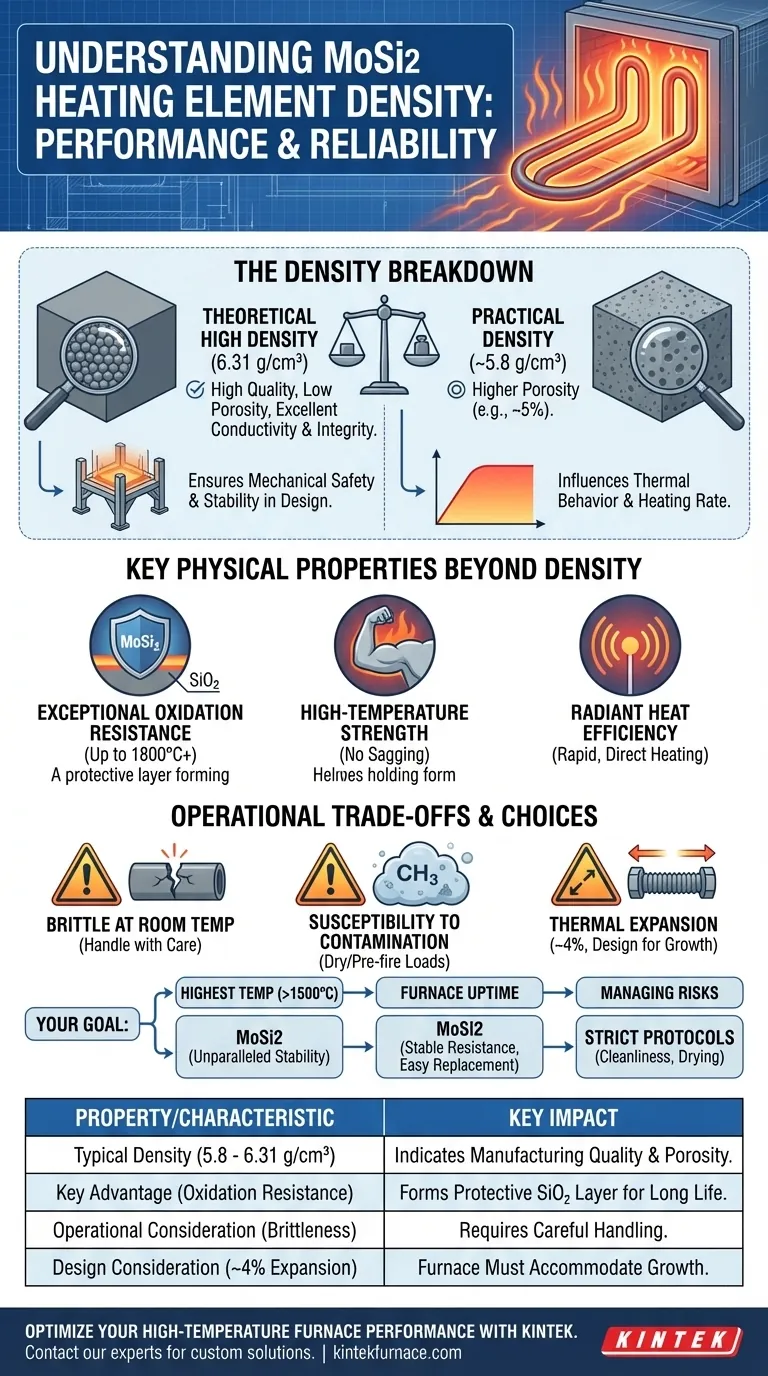

The density of MoSi2 heating elements is a critical specification with a nuanced answer. While the most commonly cited figure for high-grade Molybdenum Disilicide is 6.31 g/cm³, the practical density of a manufactured element can be lower, sometimes listed around 5.8 g/cm³. This variation is not an error but a direct result of the manufacturing process and the inherent porosity of the final ceramic component.

While the exact density figure is a useful starting point, your true goal is to understand how the material's physical properties impact furnace performance and reliability. The density is just one piece of a larger puzzle involving thermal stability, mechanical strength, and operational trade-offs.

Deconstructing the Density Figures

Understanding the two common density values is key to evaluating the quality and suitability of a MoSi2 element for your specific application.

The Theoretical vs. Practical Density

The higher value, 6.31 g/cm³, represents a nearly fully dense material. This indicates a high-quality manufacturing process with minimal internal voids, leading to excellent electrical conductivity and mechanical integrity.

A lower value, such as 5.8 g/cm³, points to a component with higher porosity. This is not necessarily a defect, but a characteristic of a particular manufacturing grade.

The Critical Role of Porosity

Porosity, which can be around 5% in some elements, refers to the tiny voids within the ceramic material. A less dense, more porous element can have slightly different properties.

While it may heat effectively, higher porosity can sometimes lead to reduced bending strength and a greater susceptibility to chemical attack from atmospheric contaminants within the furnace.

Why Density Matters for Furnace Design

Density directly translates to weight. For designers engineering furnace supports and structures, knowing the precise weight of the elements is crucial for ensuring mechanical safety and stability, especially in large industrial furnaces with dozens of elements.

Furthermore, the mass of the element influences its thermal behavior, affecting how quickly it can ramp up to temperature and cool down.

Key Physical Properties Beyond Density

Density alone does not define a MoSi2 element's performance. Its value comes from a unique combination of properties that make it ideal for extreme-temperature environments.

Exceptional Oxidation Resistance

At high temperatures, MoSi2 forms a protective, self-healing layer of pure silica (SiO₂). This glass-like coating prevents the underlying material from oxidizing, which is why these elements can operate continuously in air at temperatures where most metals would be destroyed.

High-Temperature Strength

MoSi2 elements exhibit excellent strength and stability at extreme operating temperatures. This allows them to maintain their shape and integrity under high thermal loads without sagging or deforming, a common failure point for lesser materials.

Radiant Heat and Efficiency

These elements primarily emit radiant heat. This form of energy transfer is highly efficient, allowing for direct and rapid heating of the workload within the furnace with minimal energy loss.

Understanding the Trade-offs

No material is perfect. The unique properties of MoSi2 bring a specific set of operational challenges that must be managed to ensure a long service life.

Brittleness at Room Temperature

Like most advanced ceramics, MoSi2 elements are very brittle at ambient temperatures. They must be handled with extreme care during installation and maintenance to avoid fracture from mechanical shock or impact.

Susceptibility to Contamination

The protective silica layer is vulnerable to certain chemical vapors. A common operational error is failing to properly dry or pre-fire materials, like painted zirconia, which can release contaminants that attack the elements and cause premature failure.

Thermal Expansion

MoSi2 has a thermal expansion coefficient of around 4%. This means the elements will physically grow in length as they heat up. Furnace designs must incorporate flexible terminal straps and sufficient clearance to accommodate this expansion and prevent mechanical stress.

Making the Right Choice for Your Goal

Selecting the correct heating element requires balancing performance requirements with operational realities.

- If your primary focus is achieving the highest possible operating temperatures (above 1500°C): MoSi2 is the definitive choice due to its unparalleled oxidation resistance and thermal stability.

- If your primary focus is furnace uptime and long-term reliability: The stable electrical resistance of MoSi2, which allows you to replace a single failed element without affecting the others, provides a significant advantage.

- If your primary focus is managing operational risks: You must commit to strict furnace protocols, particularly regarding workload cleanliness and proper drying procedures, to prevent element contamination.

Understanding these material characteristics empowers you to design and operate high-temperature systems for maximum performance and longevity.

Summary Table:

| Property | Value / Characteristic | Key Impact |

|---|---|---|

| Typical Density | 5.8 - 6.31 g/cm³ | Indicates manufacturing quality and porosity level. |

| Key Advantage | Exceptional Oxidation Resistance | Forms protective SiO₂ layer for long life in air up to 1800°C+. |

| Operational Consideration | Brittle at Room Temperature | Requires careful handling during installation. |

| Design Consideration | ~4% Thermal Expansion | Furnace must accommodate growth during heating. |

Ready to optimize your high-temperature furnace performance?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced, high-temperature furnace solutions. Our expertise in MoSi2 elements and our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities. We can precisely tailor a solution to meet your unique experimental requirements, ensuring maximum reliability and efficiency.

Contact our experts today to discuss how we can enhance your high-temperature processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement