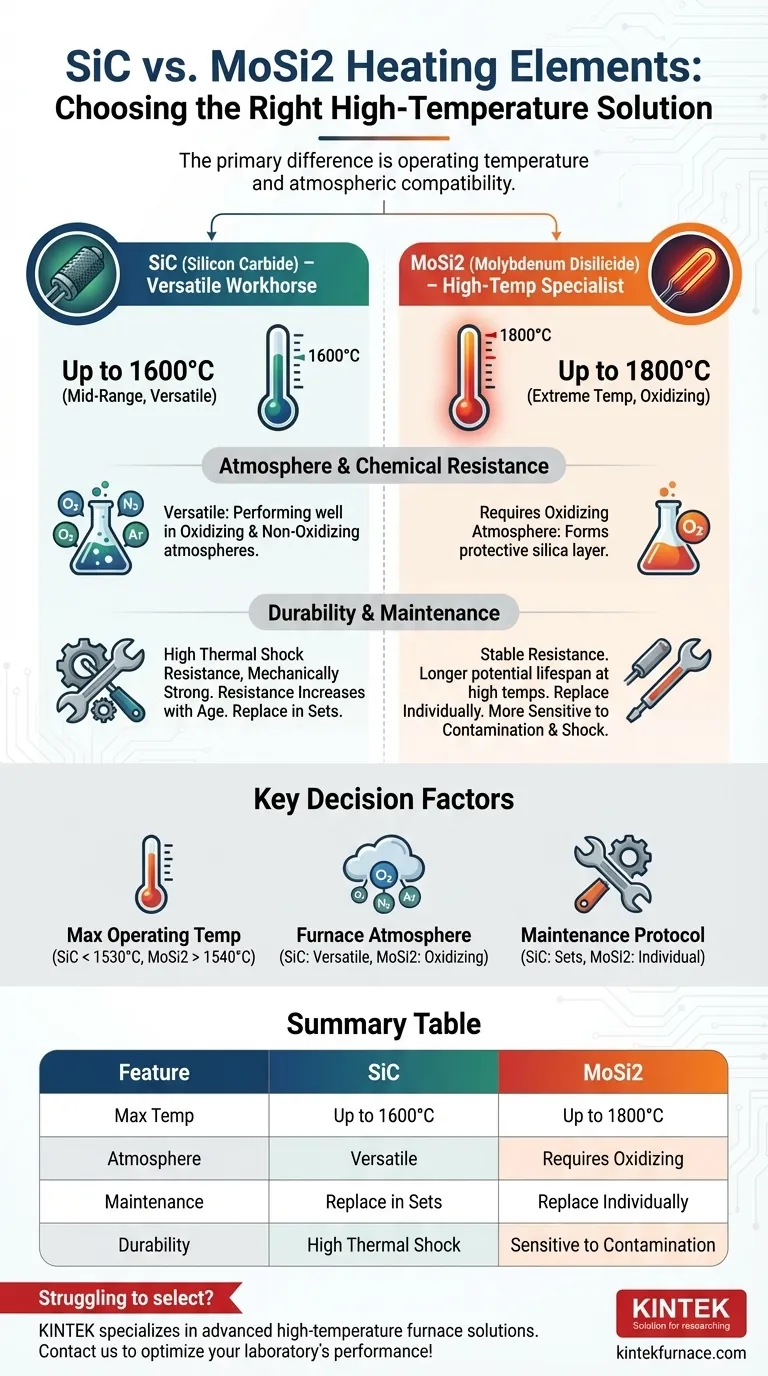

Choosing the right high-temperature heating element is a decision with significant operational and financial consequences. The primary difference is that Molybdenum Disilicide (MoSi2) elements are designed for extreme temperatures up to 1800°C within oxidizing atmospheres, while Silicon Carbide (SiC) elements are more versatile workhorses suited for a broader range of atmospheres at temperatures up to 1600°C.

The choice between SiC and MoSi2 is not about which is universally "better," but which is correctly aligned with your specific process. The decision hinges on three key factors: your maximum operating temperature, your furnace atmosphere, and your maintenance protocol.

The Defining Factor: Operating Temperature

The most critical distinction between these two materials is their effective temperature range. This single factor often makes the decision for you.

MoSi2: The High-Temperature Specialist

MoSi2 elements are the definitive choice for processes requiring furnace temperatures of 1540°C and above.

Their element surface can reach up to 1800°C, allowing for furnace operating temperatures in the 1600-1700°C range. They thrive at these high temperatures where SiC elements cannot survive.

SiC: The Versatile Mid-Range Workhorse

SiC elements are ideal for processes operating at a maximum furnace temperature of up to about 1530°C. Their optimal and most common use range is typically up to 1450°C.

While they cannot reach the extreme temperatures of MoSi2, they offer excellent performance and stability within their designated range.

Atmosphere and Chemical Resistance

The environment inside the furnace dramatically impacts element performance and lifespan.

Why MoSi2 Demands an Oxidizing Atmosphere

MoSi2 elements achieve their remarkable high-temperature stability by forming a protective, self-healing glass-like layer of silica (SiO2) on their surface.

This layer requires an oxidizing atmosphere (one containing oxygen) to form and regenerate. In other atmospheres, this protective layer can degrade, making the element vulnerable to contamination and rapid failure.

SiC's Adaptability Across Environments

SiC elements are significantly more versatile. They perform reliably across a broader range of atmospheric conditions, not just oxidizing ones.

This makes SiC a more forgiving and robust choice if your process involves varying or non-oxidizing atmospheres.

Understanding the Trade-offs: Durability and Maintenance

Beyond temperature and atmosphere, the practical realities of element lifespan and maintenance protocols are critical.

The Aging Process of SiC Elements

As SiC elements are used, their electrical resistance gradually increases. This is a natural and unavoidable part of their aging process.

Because of this change, a new element will have a different resistance than the old ones. Therefore, when one SiC element fails, you must replace the entire set (or at least a parallel bank) to ensure the furnace heats evenly.

Lifespan and Maintenance of MoSi2

MoSi2 elements can have a longer lifespan than SiC, especially when operated consistently above 1500°C. Critically, their resistance does not change significantly with age.

This means you can replace a single failed MoSi2 element without affecting the others, which can significantly reduce long-term maintenance costs. However, they are less physically robust and require more careful handling and furnace maintenance to prevent contamination.

Physical and Thermal Durability

SiC is a mechanically stronger material with superior thermal shock resistance. This makes it more durable during rapid heating and cooling cycles.

MoSi2, while more ductile at high temperatures, can be more susceptible to physical damage and contamination if furnace maintenance is not performed correctly.

Making the Right Choice for Your Process

Your selection must be a deliberate match for your operational needs. Use these guidelines to make a clear decision.

- If your primary focus is extreme temperature (1540°C+): MoSi2 is the only suitable choice, provided you can maintain an oxidizing atmosphere.

- If your primary focus is mid-range temperature (up to ~1530°C): SiC offers a robust, cost-effective, and atmospherically versatile solution.

- If your primary focus is rapid thermal cycling or physical robustness: SiC's superior thermal shock resistance and mechanical strength make it the more durable option.

- If your primary focus is minimizing replacement costs at high temperatures: Well-maintained MoSi2 elements are often more economical due to their individual replacement capability.

By aligning your element choice with your specific process parameters, you ensure optimal performance, longevity, and cost-efficiency for your high-temperature application.

Summary Table:

| Feature | SiC Heating Elements | MoSi2 Heating Elements |

|---|---|---|

| Max Operating Temperature | Up to 1600°C | Up to 1800°C |

| Atmosphere Compatibility | Versatile (oxidizing and non-oxidizing) | Requires oxidizing atmosphere |

| Lifespan and Maintenance | Resistance increases with age; replace in sets | Stable resistance; replace individually |

| Durability | High thermal shock resistance, mechanically strong | Less robust, sensitive to contamination |

Struggling to select the right heating element for your high-temperature processes? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, enhancing efficiency and reducing costs. Don't let element choice hold you back—contact us today to discuss how KINTEK can optimize your laboratory's performance with reliable, customized heating solutions!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality