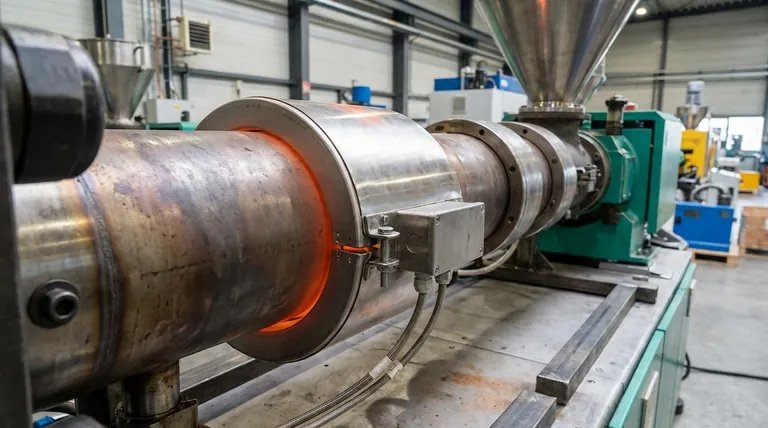

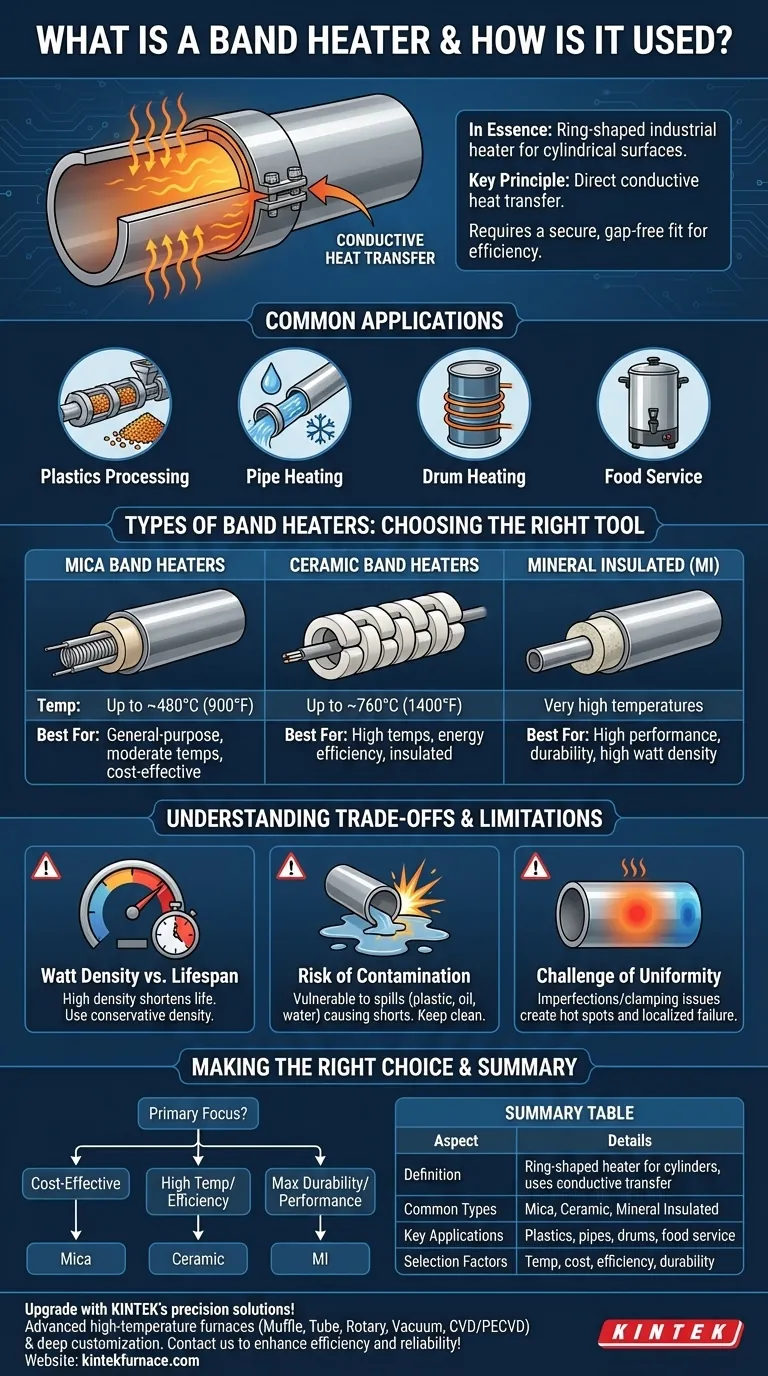

In essence, a band heater is a ring-shaped industrial heating device designed to clamp around a cylindrical surface. It functions by conducting heat directly into the object it encircles, making it highly efficient for heating the contents of pipes, barrels, and nozzles. These heaters are workhorses in industries like plastics processing, where they are used to heat the barrels of injection molding and extrusion machines.

The core principle of a band heater is its simplicity and directness. However, its performance and lifespan are not guaranteed; they depend entirely on selecting the correct heater type for the application and ensuring a tight, uniform fit for maximum conductive heat transfer.

The Core Principle: Conductive Heat Transfer

A band heater's effectiveness is rooted in its ability to make direct physical contact with the surface it needs to heat. Understanding this principle is key to using them correctly.

From Strip to Ring

At its most basic, a band heater is simply a strip heater—a flat heating element—that has been formed into a circular or semi-circular shape. This allows it to be fitted snugly around a cylinder.

The Critical Role of Clamping

Band heaters transfer energy primarily through conduction. This requires a secure, gap-free fit between the heater's inner surface and the cylinder wall. Any air gaps act as insulators, trapping heat in the heater itself, which leads to inefficiency and premature burnout. Proper clamping is non-negotiable for performance.

Common Applications

While the plastics industry is a primary user, band heaters are found in any process requiring reliable heat on a cylindrical surface. This includes:

- Plastic Injection Molding & Extrusion: Melting plastic pellets inside the machine barrel.

- Pipe Heating: Maintaining fluid temperature or preventing freezing in pipes.

- Drum Heating: Warming the contents of 55-gallon drums to lower viscosity.

- Food Service: Heating kettles, coffee urns, and other cylindrical vessels.

Types of Band Heaters: Choosing the Right Tool

The specific construction of a band heater dictates its operating temperature, efficiency, and lifespan. Selecting the right type is the most critical decision you will make.

Mica Band Heaters

Mica band heaters are the most common and cost-effective option. They use a nickel-chrome resistance wire wound around a mica core, which is then enclosed in a sheet metal sheath. They are excellent for general-purpose applications with moderate temperature requirements (up to ~900°F / 480°C).

Ceramic Band Heaters

For higher temperatures and improved energy efficiency, ceramic band heaters are the superior choice. They consist of interlocking ceramic "knuckles" that house the resistance wire. This construction allows them to operate at higher temperatures (up to ~1400°F / 760°C) and provides a degree of insulation, which can reduce ambient heat loss and lower energy costs.

Mineral Insulated (MI) Band Heaters

Mineral insulated heaters represent the high-performance tier. The heating element is encased in a dense mineral insulation (typically magnesium oxide) within a seamless metal sheath. This robust design provides exceptional heat transfer, high durability, and the ability to handle very high watt densities, making them ideal for the most demanding applications.

Understanding the Trade-offs

While powerful, band heaters are not without limitations. Acknowledging these potential issues is crucial for successful implementation and a long service life.

Watt Density vs. Heater Lifespan

Watt density is the measure of heat output per square inch of the heater's surface. Pushing for a very high watt density to achieve faster heat-up times will dramatically shorten the heater's lifespan. It is always better to use a larger or more efficient heater at a conservative watt density.

The Risk of Contamination

Band heaters are vulnerable to contamination. Spills of materials like melted plastic, oil, or even water can seep into the heater's internal components, causing electrical shorts and immediate failure. A clean operating environment is essential.

The Challenge of Uniformity

Achieving perfectly uniform heat across the entire surface can be difficult. Minor imperfections in the cylinder's surface or improper clamping can create hot spots on the heater, leading to localized failure while other parts of the cylinder remain under-heated.

Making the Right Choice for Your Application

Selecting the correct band heater involves matching the technology to your specific operational goals, budget, and temperature requirements.

- If your primary focus is cost-effective, general-purpose heating: A mica band heater provides the best balance of performance and price for moderate temperatures.

- If your primary focus is high temperatures or energy efficiency: A ceramic band heater will deliver longer life and lower ambient heat loss, justifying its higher initial cost.

- If your primary focus is maximum durability and performance: A mineral insulated (MI) band heater is the most robust solution for mission-critical applications with high watt density demands.

By matching the heater technology to your operational demands, you ensure reliable, efficient, and long-lasting thermal performance for your process.

Summary Table:

| Aspect | Details |

|---|---|

| Definition | Ring-shaped industrial heater for cylindrical surfaces, using conductive heat transfer. |

| Common Types | Mica (up to 480°C), Ceramic (up to 760°C), Mineral Insulated (high durability). |

| Key Applications | Plastics processing, pipe heating, drum warming, food service equipment. |

| Selection Factors | Temperature needs, cost, efficiency, and durability requirements. |

Upgrade your industrial heating with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures we meet your unique experimental and production needs. Contact us today to discuss how our band heaters and other products can enhance your efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights