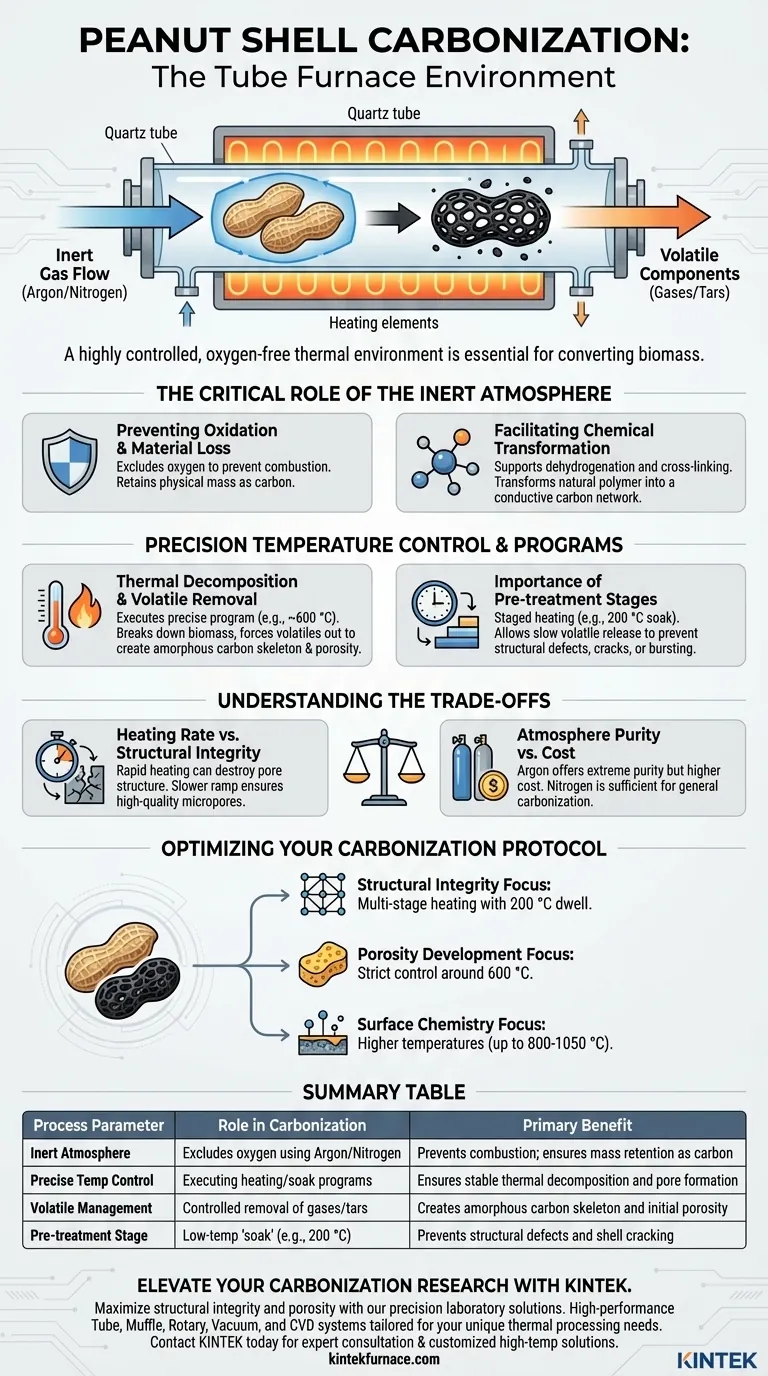

A tube furnace creates a highly controlled, oxygen-free thermal environment essential for converting biomass. Specifically, it provides a strictly controlled inert atmosphere—typically using argon—paired with precise temperature regulation programs, often operating around 600 °C. This environment facilitates the thermal decomposition of peanut shells and the controlled removal of volatile components to form a stable amorphous carbon skeleton with initial porosity.

By isolating peanut shells in an inert gas flow and applying exact heating profiles, the tube furnace ensures the biomass converts into a stable carbon structure rather than ash. The controlled removal of volatiles is the critical mechanism that defines the material's final porosity and strength.

The Critical Role of the Inert Atmosphere

Preventing Oxidation and Material Loss

The primary function of the tube furnace environment is to exclude oxygen. In a standard open-air environment, heating peanut shells to 600 °C would result in combustion, leaving behind only ash.

The tube furnace utilizes a continuous flow of inert gas, such as argon or nitrogen. This creates a protective shield that prevents the carbon material from being lost to oxidation, ensuring the physical mass of the shell is retained as carbon.

Facilitating Chemical Transformation

Within this inert environment, the furnace drives complex chemical changes. The atmosphere supports processes like dehydrogenation and cross-linking of polymer precursors.

This allows the organic structures within the peanut shell to break down chemically without reacting with the air, transforming the natural polymer network into a conductive or semi-conductive carbon network.

Precision Temperature Control and Programs

Thermal Decomposition and Volatile Removal

The furnace does not simply heat the material; it executes a precise temperature control program. At operating temperatures such as 600 °C, the heat energy breaks down the biomass structure.

This heat forces volatile components (gases and tars) to exit the shell. As these volatiles vacate the material, they leave behind voids, effectively creating the amorphous carbon skeleton and establishing the material's initial porosity.

The Importance of Pre-treatment Stages

An advanced tube furnace environment allows for staged heating, which is critical for structural integrity. For example, a protocol may include a low-temperature pretreatment stage, such as holding at 200 °C for several hours.

This "soak" period facilitates the slow, controlled release of volatile substances. By avoiding a rapid spike in temperature, the process prevents structural defects, cracks, or bursting that can occur if gases accumulate and expand too quickly inside the shell.

Understanding the Trade-offs

Heating Rate vs. Structural Integrity

A common pitfall in this process is prioritizing speed over stability. While the furnace can reach high temperatures quickly, rapid heating often leads to the destruction of the pore structure.

If the volatile components are expelled too violently, the carbon skeleton may collapse or fracture. Achieving high-quality micropore structures requires a slower, more deliberate temperature ramp.

Atmosphere Purity vs. Cost

While argon provides an excellent inert environment, it is more expensive than nitrogen. The choice of gas affects the process environment.

Nitrogen is often sufficient for general carbonization (e.g., at 800 °C - 850 °C), but if the goal is to preserve highly specific internal crystalline phases or achieve extreme purity, the stricter inert nature of argon may be required to prevent even trace nitridation or oxidation.

Optimizing Your Carbonization Protocol

The effectiveness of peanut shell carbonization depends on how you program the furnace environment to match your specific material goals.

- If your primary focus is Structural Integrity: Implement a multi-stage heating program with a dwell time around 200 °C to allow volatiles to escape without cracking the shell.

- If your primary focus is Porosity Development: Ensure strict temperature control around 600 °C to maximize the removal of volatiles while maintaining the amorphous carbon skeleton.

- If your primary focus is Surface Chemistry: Utilize higher temperatures (up to 800 °C or 1050 °C) to drive deeper dehydrogenation and increase conductivity.

The tube furnace is not merely a heating element; it is a precision reactor that governs the transition from raw biomass to functional carbon material.

Summary Table:

| Process Parameter | Role in Carbonization | Primary Benefit |

|---|---|---|

| Inert Atmosphere | Excludes oxygen using Argon/Nitrogen | Prevents combustion; ensures mass retention as carbon |

| Precise Temp Control | Executing heating/soak programs | Ensures stable thermal decomposition and pore formation |

| Volatile Management | Controlled removal of gases/tars | Creates amorphous carbon skeleton and initial porosity |

| Pre-treatment Stage | Low-temp 'soak' (e.g., 200 °C) | Prevents structural defects and shell cracking |

Elevate Your Carbonization Research with KINTEK

Maximize the structural integrity and porosity of your biomass materials with KINTEK’s precision laboratory solutions. Backed by expert R&D and manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for researchers and industrial labs. Whether you require argon-pure environments or multi-stage programmable heating for peanut shell carbonization, our furnaces are fully customizable to meet your unique thermal processing needs.

Ready to optimize your carbon structure? Contact KINTEK today for expert consultation and customized high-temp solutions

Visual Guide

References

- João Ferreira, J. C. R. E. Oliveira. High‐Capacity Hybrid Electrode for Seawater Batteries with Bio‐Waste Electrocatalyst. DOI: 10.1002/ente.202501038

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a Horizontal Tube Furnace used for the torrefaction of Refuse Derived Fuel (RDF)? Boost Fuel Efficiency Now

- Why is a tube furnace with precise temperature control necessary for synthesizing high-quality monolayer MoS2?

- Why is an atmosphere-protected tube furnace preferred for LMTOF1244? Ensuring Precise Chemical Stoichiometry

- What are the advantages of a dual-zone tube furnace for APCVD of SnSe2? Master Phase Purity & Stoichiometry

- What thermal processes can tube furnaces be used for? Unlock Precision in Material Processing

- How do split tube furnaces provide access to the chamber? Unlock Easy Sample Handling for Your Lab

- How have tube furnaces evolved over time? From Basic Heating to Precision Control

- How does the use of a tube furnace for nitrogen-protected annealing affect tin oxide catalysts? Unlock Superior Activity