The evolution of the tube furnace is a story of transformation from a simple heating device into a highly sophisticated, digitally controlled processing environment. Initially used for basic heat treatment, modern tube furnaces are now indispensable tools in advanced fields like semiconductor manufacturing, nanomaterial synthesis, and aerospace ceramics, driven by massive leaps in control, precision, and atmospheric management.

The core evolution is a shift from merely generating high heat to meticulously controlling the entire thermal process. Modern furnaces are defined not just by their temperature, but by their ability to program complex heating profiles, maintain ultra-pure atmospheres, and log data with digital precision.

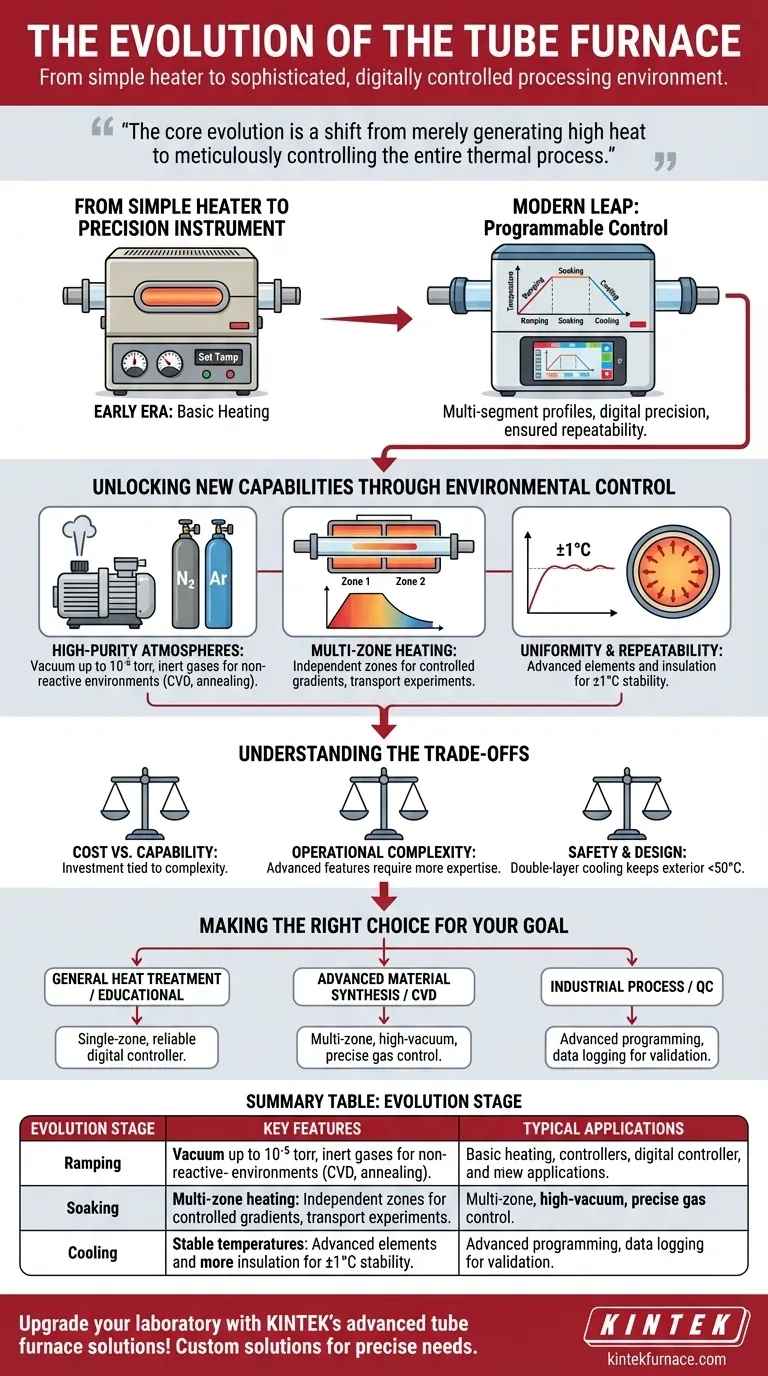

From Simple Heater to Precision Instrument

The earliest tube furnaces were straightforward devices. Their evolution into the instruments we see today is marked by a dramatic increase in control over the heating process itself.

The Era of Basic Heating

Early models offered rudimentary control, often with analog dials to set a single target temperature. Their primary function was to heat a sample, with less emphasis on the rate of heating, cooling, or achieving perfect temperature uniformity across the chamber.

The Leap to Programmable Control

The single most significant evolution is the integration of digital controllers. Modern furnaces feature multi-segment programming, allowing users to define complex thermal profiles with specific ramping (rate of temperature increase), soaking (holding at a temperature), and cooling stages.

These controllers often feature color touchscreens, preset recipes for common processes like sintering, and the ability to program dozens of steps to perfectly match the requirements of a sensitive material or chemical reaction. This programmability ensures repeatability, a critical factor in both scientific research and industrial production.

Unlocking New Capabilities Through Environmental Control

Concurrent with advances in temperature control was the development of precise atmospheric control. This capability transformed the tube furnace from a simple oven into a self-contained, highly specific reaction chamber.

Achieving High-Purity Atmospheres

Many advanced materials are highly reactive with oxygen at elevated temperatures. Modern furnaces address this by incorporating vacuum systems capable of reaching levels as low as 10⁻⁵ torr.

Furthermore, integrated gas mixing systems allow for the introduction of specific inert gases, like nitrogen or argon, to create a protective, non-reactive environment. This is essential for preventing oxidation and enabling processes like annealing and certain types of chemical vapor deposition (CVD).

Mastering Gradients with Multi-Zone Heating

While single-zone furnaces are designed for maximum temperature uniformity, advanced applications sometimes require a controlled temperature gradient. Multi-zone furnaces, which feature two or more independently controlled heating sections along the tube's length, were developed for this purpose.

This capability is crucial for transport experiments, where a substance is moved from a hot zone to a cooler zone, and for specialized CVD processes where different temperature zones facilitate distinct stages of a reaction.

Ensuring Uniformity and Repeatability

The classic cylindrical chamber, combined with advanced heating elements and insulating materials, is inherently designed for uniform heat distribution. Modern furnaces achieve a temperature stability of ±1°C, ensuring that every part of a sample experiences the same thermal conditions. This precision is the foundation for achieving consistent and reliable results.

Understanding the Trade-offs

The evolution of these features has introduced a spectrum of choices, each with its own considerations.

Cost vs. Capability

A simple, single-zone furnace for general heat treatment is significantly less expensive than a multi-zone system equipped with high-vacuum pumps and a digital gas-mixing controller. The required investment is directly tied to the complexity of the process you need to perform.

Operational Complexity

With greater capability comes greater complexity. A furnace with 30-segment programming, vacuum control, and multiple gas inputs requires more user expertise to operate safely and effectively than a basic model. Proper training is essential to leverage its full potential and avoid damaging the equipment or the sample.

Safety and Design

Modern furnaces incorporate features like a double-layer cooling shell to keep the exterior surface temperature below 50°C, even when the interior is at 1500°C or more. This dramatically improves operator safety and makes the units suitable for placement on a standard laboratory bench.

Making the Right Choice for Your Goal

Selecting the right tube furnace means matching its evolved capabilities to your specific application.

- If your primary focus is general heat treatment or educational use: A robust, single-zone furnace with a reliable digital controller is often sufficient.

- If your primary focus is advanced material synthesis or CVD: A multi-zone furnace with high-vacuum capability and a precise gas control system is essential.

- If your primary focus is industrial process development or quality control: A furnace with advanced programming, preset curves, and integrated data logging for process validation is critical.

Understanding this journey from a basic heater to a precision instrument empowers you to select the exact tool needed to achieve your scientific or industrial objectives.

Summary Table:

| Evolution Stage | Key Features | Typical Applications |

|---|---|---|

| Early Models | Basic analog controls, single temperature setting | General heat treatment, educational use |

| Modern Systems | Digital multi-segment programming, vacuum/gas control, multi-zone heating | Semiconductor manufacturing, nanomaterial synthesis, CVD processes |

| Advanced Capabilities | High temperature stability (±1°C), data logging, safety features | Aerospace ceramics, industrial quality control, transport experiments |

Upgrade your laboratory with KINTEK's advanced tube furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Tube, Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your specific applications and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability