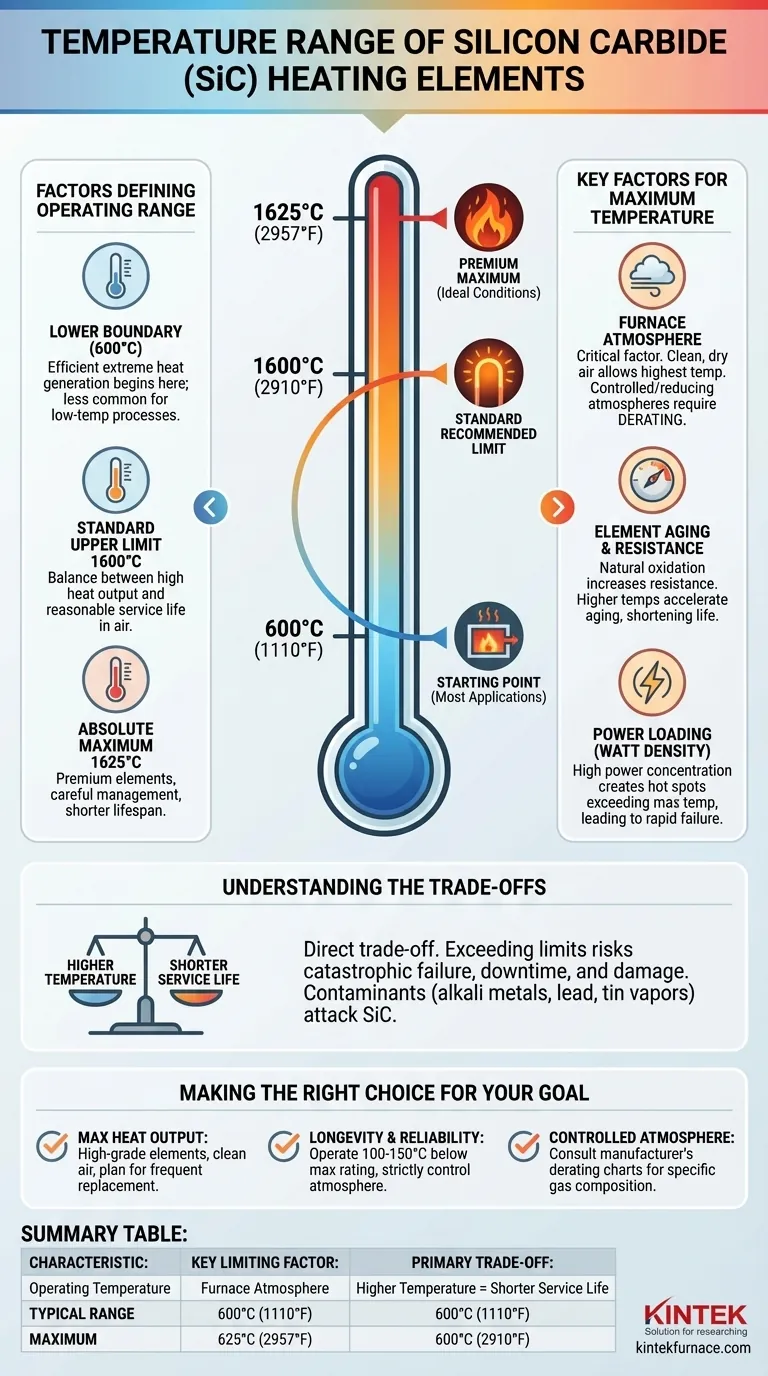

In practice, silicon carbide (SiC) heating elements operate in a temperature range from approximately 600°C (1110°F) up to 1600°C (2910°F). While this is the typical range, certain high-grade elements can be pushed to a maximum temperature of 1625°C (2957°F) under ideal conditions.

The maximum temperature of a silicon carbide element is not a single, fixed number. It is a dynamic limit determined primarily by the furnace atmosphere, the element's age, and its power loading, all of which directly impact its service life and performance.

The Factors Defining the Operating Range

To effectively use SiC elements, you must understand what governs their performance at both the low and high ends of their temperature spectrum.

The Lower Temperature Boundary

Most applications for SiC elements begin around 600°C (1110°F). While they can function at lower temperatures, their primary advantage is their ability to generate extreme heat efficiently, making them less common for low-temperature processes.

The Standard Upper Temperature Limit

For most standard applications in an air atmosphere, the maximum recommended element temperature is 1600°C (2910°F). This provides a good balance between high heat output and a reasonable service life.

Pushing to the Absolute Maximum

Some premium SiC elements are rated for operation up to 1625°C (2957°F). Operating at this level requires careful management of the furnace environment and will typically shorten the element's lifespan.

Key Factors That Determine Maximum Temperature

The catalog temperature rating is only a starting point. Real-world performance is dictated by the specific conditions of your process.

Furnace Atmosphere

The single most critical factor is the atmosphere inside the furnace. The highest temperatures are achievable in a clean, dry air atmosphere.

Controlled or reducing atmospheres (like nitrogen, argon, or forming gas) can react with the silicon carbide at high temperatures. This requires you to "derate," or lower, the maximum operating temperature to prevent premature element failure.

Element Aging and Resistance

SiC elements are not static components. Over their operational life, they slowly oxidize, which causes their electrical resistance to increase.

This aging process is a natural and expected part of their lifecycle. However, running the elements at higher temperatures will accelerate this aging, increase resistance faster, and shorten their useful service life.

Power Loading (Watt Density)

Power loading refers to how much power is concentrated over the element's surface area. Excessively high power loading can create localized hot spots on the element.

These hot spots can easily exceed the material's maximum temperature limit, even if the overall furnace temperature is within range, leading to a rapid failure.

Understanding the Trade-offs

Choosing and operating an SiC element involves balancing performance goals with practical limitations. Misunderstanding these trade-offs is a common source of problems.

Temperature vs. Service Life

There is a direct and unavoidable trade-off between operating temperature and the element's lifespan. An element consistently run at 1600°C will have a significantly shorter life than the same element run at 1450°C.

The Cost of Exceeding Limits

Pushing an element beyond its recommended temperature for a given atmosphere doesn't just reduce its life; it risks catastrophic failure. A broken element can cause significant downtime and potentially damage the product or furnace insulation.

Contamination Risks

Certain chemicals and metals can aggressively attack silicon carbide at high temperatures. Vapors from alkali metals, lead, or tin can create low-melting-point compounds that corrode the element, drastically reducing both its maximum temperature capability and its lifespan.

Making the Right Choice for Your Goal

The optimal operating temperature depends entirely on your process priorities. Use the manufacturer's data sheets as your primary guide, but consider these principles.

- If your primary focus is maximum heat output: Use high-grade elements in a clean air atmosphere and plan for a more frequent replacement schedule.

- If your primary focus is longevity and reliability: Operate your elements at least 100-150°C below their maximum rating and strictly control furnace atmosphere and cleanliness.

- If you are using a controlled or reducing atmosphere: You must consult the manufacturer's specific derating charts for your exact gas composition to determine a safe maximum temperature.

Treating the maximum temperature as a guideline influenced by your specific conditions, not as a fixed target, is the key to a successful high-temperature process.

Summary Table:

| Characteristic | Typical Range | Maximum (Premium Elements) |

|---|---|---|

| Operating Temperature | 600°C - 1600°C (1110°F - 2910°F) | Up to 1625°C (2957°F) |

| Key Limiting Factor | Furnace Atmosphere | Power Loading & Element Age |

| Primary Trade-off | Higher Temperature = Shorter Service Life |

Need a high-temperature furnace solution tailored to your exact process requirements?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements—ensuring optimal performance and longevity for demanding applications like those using silicon carbide heating elements.

Contact our experts today to discuss how we can design a furnace system that balances extreme temperature performance with reliability for your specific goals.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions